If you’re new to the world of 3D printing, then you have probably heard about these two printer types; The Cartesian and the Delta 3D printers.

While both are FDM printers, meaning that they extrude plastic and create layer upon layer in order to create the 3D object, they are also quite different, be it in price, print quality, and just overall print speed.

In this article, I will be going over the difference between Cartesian and Delta printers, their pros and cons, and which one you should go for in most situations.

So, in short: Delta printers, while harder to set up and to troubleshoot, have a much faster print time than Cartesian printers and all of this at the cost of slightly worse print quality unless the settings have been dialed in perfectly. Cartesian printers on the other hand, are the best type of printer for most people since printing with them is easier and the overall print quality tends to be better.

Now, without further ado, let’s get started!

Main differences between Delta and Cartesian printers

In FDM 3D printing, there are two types of printing systems that are vastly different from each other due to their printing methods, and this means that they will produce different quality results and print at different speeds, and of course, I’m talking about Cartesian and Delta 3D printer.

Although Delta 3D printers also use the Cartesian coordinate system, they do not use linear-motion tracked movement in their filament layer depositions. Delta 3D printers have a round print bed and use three arms to control the printer head over the printing space. Their movements are coordinated through changes in the angles of the parallelograms, which is the core of their movements.

Print accuracy is achieved through the use of three print arms not weighed down by motors, so with the reduced inertia, the head response time is greatly improved, thus maintaining a respectable degree of print accuracy and high printing speeds.

Delta 3D printers need more height to be able to print properly, and printing large models in the horizontal plane can be a limiting factor of the technology. Additionally, Delta printers are, in essence, a bit more complex than Cartesian printers, which is why getting good results won’t be as easy, and troubleshooting issues may also be much more of a headache than with Cartesian printers. However, they can print at a much faster pace, which is worth considering.

Cartesian printers operate on an X, Y, and Z coordinate system to plot extrusion points, allowing for linear movement across the 3D print space. Their movements cover left to right, front to back, and up and down. They operate with a square moving print bed that, in most cases, moves towards the nozzle.

The weight of the moving parts of a cartesian printer is what limits it the most. The weight contributes to jerking movement at stops or direction changes and may cause the prints to detach from the bed.

Lastly, Cartesian printers print at a much slower pace than Deltas’ do.

Cartesian 3D printers

Cartesian 3D printers are by far the most popular printers thanks to their consistently good quality and ability to print detailed prints with smooth finishes.

How do Cartesian 3D printers work?

Cartesian printers print on a square print bed with linear axes. The print head moves on the X and Y plane, which in turn moves on the Z-axis to create a 3D model. The print coordinates are cartesian coordinates that are relayed to the head, telling it when and where to print. Although printing is slow, high-quality prints can be expected with smooth finishes.

Difference between Cartesian and CoreXY printers

On the right: CoreXY 3D Printer.

Technically speaking, most printers are rooted in cartesian technology principles, but some types of printers have introduced different design dimensions into their technology which gives them unique characteristics. You can view the technology behind a printer as its unique identity that originated from cartesian principles.

The exception might be Polar printers with their spinning bed, yet the technology is founded on the cartesian principles (more on these types of printers in a second).

The main differences between CoreXY printers and Cartesian printers are:

- The print speed; the CoreXY prints faster than the Cartesian printers.

- CoreXY printers use belts as opposed to Cartesian printers, which print using X, Y, and Z axes on a fixed print bed.

- CoreXY printers move at 45 degrees.

- The initial set up of the printers is much easier with Cartesian printers than with CoreXY printers

- The CoreXY is smaller in design yet is able to produce the same quality prints as a Cartesian printer.

Advantages of cartesian printers

Cartesian printers are easy to understand and are user-friendly. They are also affordable -some even selling under the $100 mark- and can print a range of different types of filament. Upgrading or repairs are inexpensive, and due to their popularity, there is an abundance of community support.

Disadvantages of Cartesian printers

They are rather large with a heavy frame, yet are somewhat handicapped when it comes to printing tall or vertical structures, and although they produce great quality prints, the process is slow.

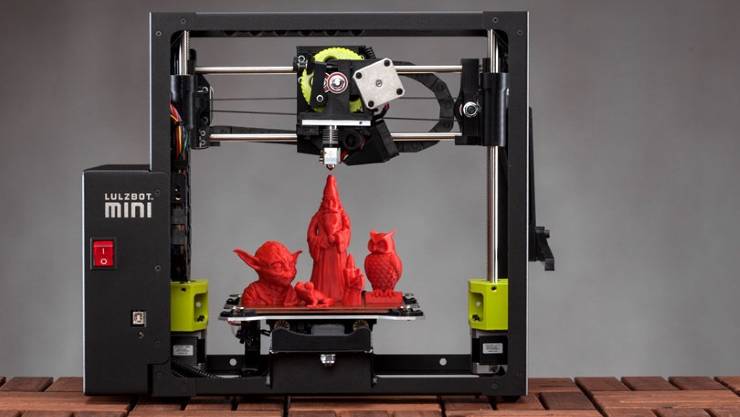

Examples of Cartesian printers

- Ender 3 (MY REVIEW | CHECK PRICE)

- Prusa i3

- MakerBot Replicator (not recommende | CHECK PRICE)

- Voxelab Aquila (CHECK PRICE)

- Advanced Creality Ender 5 Pro (CHECK PRICE)

Delta 3D printers

The Delta 3D printer was designed with fast printing in mind, which they clearly achieved, but the print quality was compromised to a certain extent, since the quality of a finished print is not as smooth as the one of a standard slow speed Cartesian printer.

The printer does, however, have a distinct advantage with accurate vertical printing, plus the printing height is usually not as limited as the one of Cartesian printers.

How do they work?

Delta 3D printers operate on a round print bed and use three arms to control the printer head over the printing space. The printer head is secured to three print arms that run on a rail system and are not inhibited by any additional weight from the motors, making the head easy to move and allowing for print speed and accuracy.

The wider the print area on the print bed, the poorer the detail and finish will be on the final product.

Bowden versus Direct drive extruders

Direct drive extruders allow for reliable printing by pushing filament directly into the printer nozzle, which allows for better extrusion, faster retraction, and requires a less powerful motor to feed the filament into the nozzle due to the short distance. An added benefit of using a direct extruder is its compatibility with a wide range of filaments, including flexible and abrasive ones.

The one downside to using a direct extruder is that it is mounted to the print head, which adds weight to it and affects printing speed, slowing it down. The extra weight can cause wobble and result in a loss of accuracy in the X and Y axes.

A Bowden extruder is mounted on the printer frame and controls the flow of filament that feeds through a PTFE Bowden tube into the hot end. The fact that the extruder is not mounted on the head means print quality is not compromised, and neither is the build volume. Bowden extruders are more compact than direct extruders taking up less space in the printer configuration.

Because friction will occur in the tube, it will naturally affect response time and may result in stringing, and in order to keep friction under control, a stronger motor is required to move the filament through the tube. The range of filaments that can be used is also cut short as the tube does not cope well with flexible and abrasive filaments.

Because Delta printers cannot support a direct extruder, there is no option but to use a Bowden extruder which, as we have seen, limits the filament types that can be used. Besides, a Direct extruder will slow printing down with the Delta printer, which defeats their whole purpose.

Advantages of delta printers?

The design and technology of the Delta printers allow for fast printing with good quality, especially with vertical or tall prints that do have too wide a base.

Another advantage is just how much cooler the printing process looks than on Cartesian printers (I know, this isn’t really an important factor, but looking at Delta printers go is much more entertaining than watching a Cartesian print).

Disadvantages of delta printers?

The wider the print area on the print bed, the poorer the detail and finish will be on the final product. It has been noted that square objects will not turn out as crispy sharp as they do with a Cartesian printer.

Examples of delta printers

- TEVO Little Monster

- Monoprice Mini Delta (CHECK PRICE)

- FLSUN QQ-S-PRO (CHECK PRICE)

When should you choose a Delta printer over a Cartesian one?

If you are looking to mostly print vertically dominant prints with a small foundation like miniatures, then a Delta 3D printer will suit your needs perfectly. Their circular print bed allows them to use the print space more efficiently, and they are also capable of printing higher prints more accurately.

Delta print heads are designed to be as light as possible to reduce vibrations and jerking with any change in movement. As a result, the print speed is increased substantially, which is the main objective of the design.

Cartesian printers tend to be more popular than Delta printers, and their wider use has made for a user-friendly service market: Spare parts are easier to find and are more affordable because of the demand volume. The great thing about Cartesian printers is that they operate on more rigid axes, which limits the room for error, but this comes at the cost of much lower printing speeds.

A reason why cartesian printers are more popular than Delta printers is that they are supplied already assembled (most of the times, especially the higher-end ones), whereas Delta printers arrive in kit form and have to be assembled first.

Note: If you’re reading this because you’re trying to decide what your first 3D printer should be, then no matter if you choose Cartesian or Delta, I’d recommend starting with one that you need to assemble yourself, like the Prusa Mini.

The reason for this is that building the machine yourself will help you understand the printer better, and replacing parts or troubleshooting some issues will be much easier than if you had bought it already assembled… Plus, it’s fun!

Which one is better suited for beginners and why?

Getting into 3D printing can be scary simply because there is so much new stuff to learn. For example; To be a good artist, you should at least study the artistic styles of the masters, and from that, you can develop your own style and medium to work with. 3D printing is no different, and only by experiencing the benefits and limitations of both Delta and Cartesian printers will you find your comfort zone.

Related: check out this article I wrote about whether or not it’s difficult to learn to 3D print.

Because Cartesian printers are easy to maintain and produce great quality prints, I believe -along with many other makers- that Cartesian printers are by far the best ones for inexperienced users.

This does not mean that Delta printers are inferior, but the Cartesian printers take first place when it comes to smoothly finished prints and ease of use.

Delta printers have their benefits too, and although they are somewhat limited when it comes to big horizontal sized prints, they make up for that on the vertical side of things, plus they can complete a print in much less time.

Choosing between the printer types depends on your budget and what you actually want to print. If you are looking to experiment with different filament types, then I strongly recommend a Cartesian printer because it can handle different thermoplastics with ease (usually). If budget and space are not an issue, then invest in both, which put you in a position to enjoy the best of both worlds.

But for most people, Cartesian is the way to go.

Which one can print at faster speeds and why?

Delta 3D printers dominate the printing speed charts because they are specifically designed for it. The weight of moving parts has been reduced, giving the delta head more agility with smooth, fluent movements. Furthermore, the printer head is stabilized by the three arms that run vertically on a rail system.

This, however, means that the printer might run into some issues more often than a Cartesian printer, and achieving a higher print quality will be slightly harder.

Which one is better suited for jobs where quality and high detail are important?

Cartesian 3D printers are better for quality and detail; They are capable of fine detail and precision printing, but the printing process is much slower than what you can achieve on a Delta printer.

Between Delta and Cartesian printers, Cartesian printers print great quality finishes that are smoother to the touch. Obviously, it all depends on the printer settings, but we presume that all the print parameters have been correctly set. The detail is something that matters immensely in 3D printing, and Cartesian printers do not compromise on detail, hence their extreme popularity and ever-growing user base.

There is a constant drive to improve print quality and finish. With a fine-tuned Cartesian printer, you can enhance your print quality by using a high-quality extruder and hotend combination. It won’t hurt to look at long-life precision nozzles so you can maintain the standards you set for yourself.

Other types of Fused Deposition Modeling 3D printers

There are a few different types of 3D printers on the market that are not as popular, mostly because of the technology used and the actual application of the printers. Let’s have a look at some of the less well-known 3D printers.

Polar Printers

Although Polar printers work on the same principals as Cartesian printers, they are not limited to a square grid with fixed axis. Instead, they depend on a circular grid and work on coordinates determined by angle and length. The big difference is that the print bed rotates to create the required angles, and the printer head moves up and down as well as left to right.

The main advantage of Polar printers is that they only use two motors to complete all the required movements, whereas Cartesian printers have three or four motors to perform the same functions. This puts the polar printer at an advantage as far as energy efficiency is concerned. Another advantage is that they can print larger objects using less space. The print quality compares to the one of Cartesian printers.

Scara Printers

Scara stands for Selective Compliance Assembly Robotic Arm, which is the technology behind these types of printers. Established in the 1980s, the technology based on Cartesian principals broke ground in 2013 with the introduction of the RepRap Morgan printer.

The unique mechanical setup of the Scara uses three motors, two of which operate the printhead on the XY plane while the third controls movement on the Z-axis. The Scara printers do not have an attached build plate, making the printer frame smaller than other printers.

Scara printers fit into industrial printing and have a relatively fast print speed; However, they lack precision and do not attract much community support because of that.

Belt printers

Belt Printers were first introduced in 2010 but only recently have affordable ones been hit the market. The idea behind a belt printer is to mass-produce the same print. With current models, the printer head is set at a 45-degree angle, and the print bed is in the form of a conveyer belt. The nice thing about belt printers is that if there is a printing problem with one of the prints, it will not carry over into the following prints. The most popular model of belt printers is definitely the Creality CR-30 (picture above).

Here is an interesting video on hobbyist belt printers.

Honorable Mention (Not an FDM Printer)

Resin printers

Resin printers work via a different technology that uses UV light to cure liquid resin and is outside the actual scope of this article, but I wanted to include them because if you’re looking to create highly detailed prints, then resin printers are by far the best ones.

However, they are more expensive, the printing material is also more expensive than filament, and resin is toxic, which means that safety precautions have to be taken. It is worth mentioning that in the last couple of years there have appeared affordable yet reliable resin printers, like the Anycubic Photon Mono.

Check out our recommended products section

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

Error processing API data.