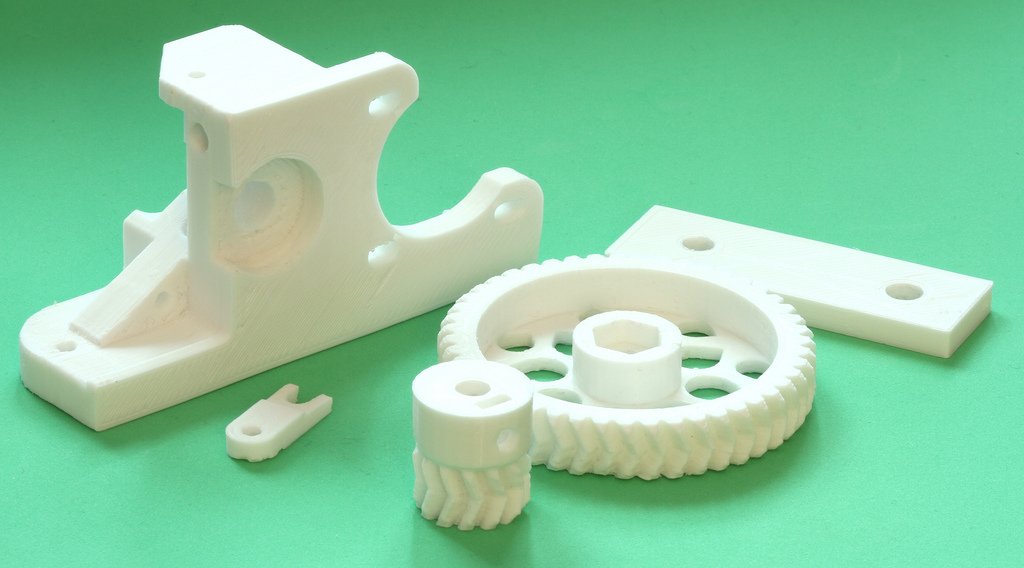

There are many types of 3D printing filaments that can be used for the purpose of making gears. Each filament has its own properties and behaviors. There are different types like Nylon, ABS, PLA, PETG, and others.

Most 3D printers come supplied with 1 type of filament so you will have to invest in others if you want to experiment with other filaments for different purposes like printing gears.

Selecting an appropriate material for your 3D printed gears is not as simple as looking at the mechanical properties since there are several other factors to consider, including ease of printing, finish quality, and cost.

In this article, I look at my favorite materials for 3D-printed gears. I’ve been experimenting with different 3d printing materials to make different types of gears and here is my conclusion.

Best 3D printing Material/filament for Gears

Basically, each and every thermoplastic filament has its pros and cons. Nylon has the best strength, PETG has the best low-temperature performance, ABS has the best impact strength and PLA is somewhere in between. Choosing between those materials is a trade-off based on your specific needs.

Generally speaking, Nylon is going to last the longest, ABS will survive slightly longer than PLA, which will in turn survive slightly longer than PETG.

Nylon is the best filament to print gears with because of its strength, resistance to high temperatures and because it doesn’t require any lubrication for the gears to work properly. PLA is a close second in terms of strength, but it can’t withstand high temperatures and will deform when it reaches 45°C-50°C. ABS and PETG are not recommended for gears.

1. Nylon

I would say if you want something that is not very brittle and is easy to print with then stick with Nylon. It is a bioplastic made from renewable sources that looks like silk and feels like silk when printing with it. It’s slick to the touch, strong, and flexible.

Nylon’s low friction coefficient, high melting temperature, and high inter-layer adhesion make it the ideal material for 3D printed gears.

However, Nylon’s great affinity for water can be problematic, as this can create inconsistent results Extrusion printers apply the material in a similar manner to a hot glue gun and the problem is that nylon absorbs water like a sponge, which causes it to swell and create all kinds of issues while printing.

Nylon filament absorbs moisture from the air, which causes the filament to swell. Between 1% and 3% water content can cause the material to fail when printed, and between 5% to 8% it begins absorbing into its 3D printed part.

This causes problems not just during the printing process, but significantly reduces the lifespan of the finished product and makes it unsuitable for outdoor use.

Given these strengths and flaws, nylon is still an excellent candidate for 3D printing gears.

Now let’s look at the three most commonly used materials in 3D printing; PLA, ABS and PETG.

2. PLA

For 3D printing, there are many great things that can be said about PLA. Let’s start with the fact that it has a low cost, coming in at $20/Kg per spool, and once you factor in the cost of electricity, since you don’t need an extremely high printing temperature like you do with ABS, PLA ends up being a fantastic filament overall.

It has excellent flexibility and still maintains good strength and wear characteristics, which is why I consider it to be a much better material for gears than ABS and PETG, but not as good as Nylon.

However, PLA can’t handle high temperatures and will start to deform even when left outside in the sun during the summer.

So, take that into account when deciding what filament to use; If the gears will be exposed to high temperatures, then consider Nylon, if not, then PLA will work wonders!

3. ABS

You have probably tried your hand at making gears with ABS, only to find that the material itself isn’t that well suited for gears.

On the one hand, since it needs to be printed at a very high temperature, with a heated bed and in an enclosed printer (generally), it might take you a couple of tries until you get your gears to print correctly since ABS is very prone to warping because of its high printing temperature.

Not only that, but if you compare two identical gears made out of PLA and ABS, the one made from ABS can’t withstand the same forces that PLA can.

In fact, try it yourself: Print a couple of gears with each material, and using pliers apply force on the gears. You will notice that the one made from ABS crushes easily, while the one made from PLA is almost indestructible.

Lastly, ABS produces toxic fumes while printing, which is another reason not to use it, at least not for gears.

4. PETG

PETG is generally a bit cheaper than ABS, and a bit more expensive than PLA.

Both PLA and ABS are cheaper, sturdier, and more rigid than PETG, which in and of itself is a good material for some things, but it isn’t the best choice for general gear design.

After reviewing data on its material properties, I am putting PETG at the bottom of my list. While it is a ductile material it is also softer, more flexible, and less scratch-resistant than either ABS or PLA, which makes it a worse choice for gears.

PETG is also hygroscopic, just like Nylon, and needs to be pre-dried before use to avoid any potential issues. Another common complaint about PETG is that it is brittle. One of the reasons for this is its lower glass transition temperature since it starts softening at 80°C, while ABS, for example, can tolerate temperatures of up to ~100°C, and nylon up to at least 120°C

So, since it’s not that great at withstanding high temperatures but it also suffers from a couple of other issues, I wouldn’t recommend PETG for gears over Nylon or PLA.

Lubrication of 3D Printed Gears

Lubrication reduces friction and wear. Now, I don’t have a good way to measure wear rates so I can’t say whether lubricating plastic parts make them last longer or not, but I can tell you from experience that in some cases, plastic parts will last longer if they are lubricated.

If you’re using teeth-bearing plastic gears rather than more robust spline-type, lubrication can reduce wear and noise and improve efficiency as well.

However, the commonly used methods of ‘smearing’ a surface with grease or oil to ward off wear and friction are less than ideal for inexperienced people as they often use the wrong kind of grease for PLA, ABS, and PETG.

The first step in choosing a proper lubricant for gears is to figure out which type of plastic you’re working with. Different types of plastics respond to different types of lubricants. A rule of thumb is that plastic filaments are often petroleum-based and will be compatible with a petroleum-based lubricant.

Nylon and ABS are polymers that are derived from petrochemicals, so they will be OK with the right oil-based lube.

PLA and PET, on the other hand, tend to have a more plant-based chemical makeup. As such, these tend to respond better to less viscous vegetable oils. By changing the type of oil or grease you use, you can tailor the performance of your printer to fit your needs.

White lithium, PTFE, and silicone-based lubricants are well suited to general use. They are the best picks for longevity without needing frequent reapplication.

However, nylon, in general, has very acceptable results and you don’t need to add any sort of physical lubrication to the gears.

I made a couple of gears that have been operating for over 3 months now with no lubrication of any kind without a single gear failure.

3D Printing Stronger Gears

While the most important factor in terms of strength is the material itself, there are a couple of print settings that might also help you achieve a stronger part.

Make Sure the filament has been heated up enough

In Fused Deposition Modeling (FDM), the printed layers have to bond together into a solid part; The first layer fuses with the last layer, and so on, and higher temperatures usually result in a better “melting together” of the layers making them stronger.

Increase Infill Overlap

Infill overlap is the area of the perimeter that overlaps with an infill layer. The overlap is necessary in order to achieve better strength between the infill and the perimeter.

Increasing your layer height will usually make it easier to achieve a good bond between an infill layer and the perimeter. However, if you choose to do so, you should avoid an exponential increase in your layer height because it can lead to curling on smaller parts.

Disable or Reduce Cooling

Layer adhesion is extremely important and the key to achieving it is to keep the printing temperature and the previous layer’s temperature high enough. This is harder to achieve when every layer is being actively cooled.

Cooling is a controversial topic in 3d printing and opinions of it range from “cooling is essential for high-quality prints” to “cooling doesn’t improve print quality at all”.

As far as I know, cooling is a big deal for 3D printing. It allows parts to be made without defects, and many difficult shapes are only possible because of cooling. But there’s a trade-off associated with cooling, which is surface quality in exchange for strength.

If your goal is to achieve maximum strength, reduce the cooling or completely disable it.

Optimum Layer height

One of the most important ‘rules’ of 3D printing speeds is that with increasing layer height, the speed is increased, while strength and quality of 3D prints decrease.

The tighter the layer height the better layer adhesion, and therefore less open space for weak spots to form in your print.

What infill should you use for Gears?

The first time I ever thought about printing gears, I was certain that 100% infill would yield the strongest gear overall.

But that wasn’t the case and the gears I printed with 50% infill were just as strong as the ones I printed with 100%.

In short, there is no need to go over 50% infill, at least not in my own experience.

Comparison Table

| Filament | Gear Quality | Nozzle Temperature | Heated Bed | Warping Risk | Ease of Use | Cost |

| PLA | Great | 180°C – 230°C | Not required | Low | Easy | $10 – $25 |

| ABS | Poor | 230°C – 250°C | Approx. 100°C | Moderate | Intermediate | $15 – $25 |

| PETG | Poor | 230°C – 250°C | Approx. 100°C | Low | Easy | $15 – $20 |

| Nylon | Best | 230°C – 260°C | 80°C – 100°C | Moderate | Intermediate | $50 – $65 |

Conclusion

Nylon is the obvious choice for all the reasons I mentioned, but most of us don’t have Nylon ready to go.

However, PLA yields fantastic results and creates strong and reliable gears and luckily, it’s a material that every maker tends to have available and ready to be printed with.

So, if you have access to Nylon, use that one. Otherwise, PLA will do just fine!

I hope this information was useful!

Have a wonderful day!

Check out our recommended products section

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

Error processing API data.

Great article. And here I was thinking PETG was going to be my best option. PLA it is then. What diameter nozzle and layer height would you suggest for a gear with a 41 DP?

Thanks.

John

I print gears with PLA at 225 nozzle temperature and .2 layer height.