If you’re thinking about getting into 3D printing, then you generally want to evaluate the costs firsts, unless you’re loaded in which case, good for you! Go buy the most expensive printer you can find as well as every type of filament and get to printing.

For the rest of us mere mortals, the cost of owning a printer, and I’m not just talking about how much the printer itself would costs, as well as getting new filament in order to continue printing, needs to be assessed.

In this article, I’m going to list the different types of filaments and their prices, and I will also include resin, so people interested in printing with resin don’t feel left out.

Ok so, let’s get this thing goin!

How expensive is 3D printing Filament?

You can expect to find PLA filament for $10 on the low end up to $25 on the higher end for a1Kg Spool, ABS and PETG can be found for $15-$25 per spool, ASA for $30-$50, Nylon for $50-$60, Polycarbonate for $30–$60, and TPE for $80-$100.

Now, let’s start this list off with the most used and beginner-friendly filament, which is PLA.

PLA

This is the most common type of filament that you’ll come across. It’s rigid and doesn’t require a heated bed to print, so it’s great for many types of projects. PLA (or polylactic acid) filament comes in a range of different colors and finishes – including glow in the dark, rainbow, glitter, and silk.

There’s very little flexibility with PLA and you’ll generally find it prints between 180°C and 230°C. You don’t need to worry about warping as much with this filament when compared to some of the others on the list, and it’s very beginner friendly.

It’s also fairly cheap, as there are many manufacturers vying for their slice of the most popular filament. You can expect to pay between $10 – $25 per kg spool; filaments with special finishes will be on the higher end of the scale whereas basic colors will fall closer to the bottom.

ABS

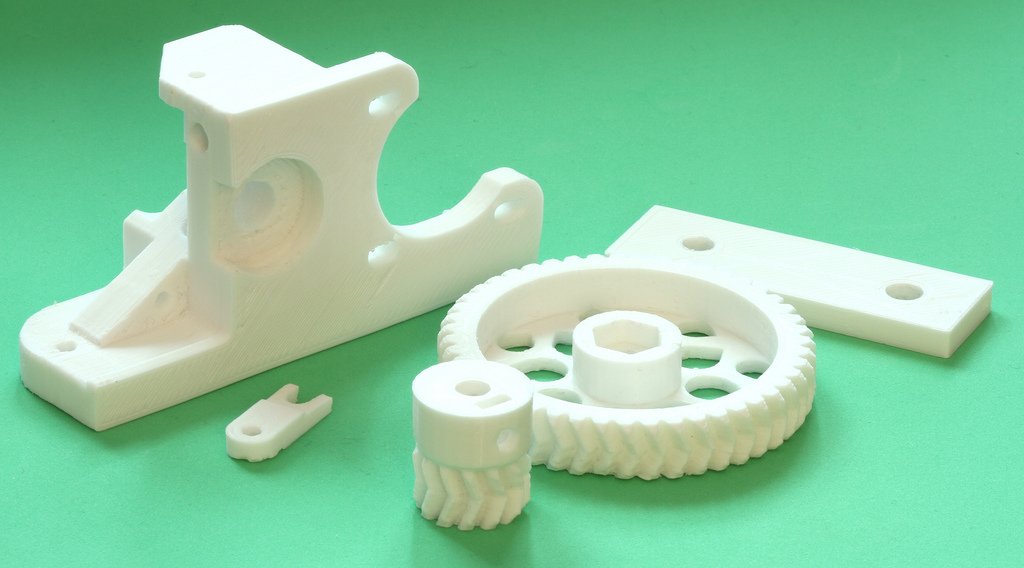

ABS, or acrylonitrile butadiene styrene, follows PLA as the second most popular type of printing filament. Materials-wise, it can be better to print with and lead to a higher quality final product, but it’s a little more complex to print with. This can deter some beginner printers who opt for PLA instead.

This material is more durable than PLA and the final print can withstand higher temperatures, however this means that you require a higher print temperature and there can be warping as it cools, and lots of it.

You’ll want to go with a higher nozzle temperature for ABS, up to 250°C, and you’ll also want to heat the bed to around 100°C. Print the first layers slowly in this material and check for warping before picking up the speed as the print progresses. Many experts advise using an enclosure for this type of printing since this will prevent warping, and it will also help slightly with the fumes that ABS generates while being printed since they can be toxic.

ABS is also an inflexible material and comes in a range of different colors and finishes. It’s similarly priced to PLA at around $15 – $25 per kg spool.

PETG

This is the same plastic that’s used in a variety of manufacturing processes, so it’s a reliable option! PET is used in the manufacture of many plastic items; PETG is a close relation to this plastic that’s been slightly modified to make it easier to use at home.

It’s less brittle than the previous types of filament that we’ve discussed, so it can be used for different projects. It’s simple to print with minimal warpage to worry about, though you’ll want to use a heated bed to ensure adhesion.

You’ll find that the material can be quite sticky as it dries so it’s not great to use for supports. Some printers even find that this material sticks to the bed a little too well, so be patient and use your spatula gently to get your print off the bed.

The bed and nozzle temperatures for this material are similar to ABS, though it’s a little easier to print with. If you’re struggling to print with ABS then you might want to switch to PETG to make the process simpler. It’s a durable material, though it can be prone to becoming scratched over time.

PETG has been coming down in price recently and now rivals ABS in cost. You can expect to pay around $15 – $20 per kg spool.

Nylon

This filament is a favorite for many printers, as it combines some of the best traits of ABS, PLA and PETG together. It’s strong but also slightly flexible, which means it’s perfect for a wide range of applications. The flexibility given by this material will depend on the thickness of the print; thinner prints will be more flexible whereas thicker prints will be more rigid.

One feature that users love about nylon is the ability to dye it – before or after printing. You can use clothing dye to add pigment to the finished project or to create a multi-colored filament. There are different types of nylon, as they’re graded with different numbers. Nylon 618 and 645 tend to be most used by home printers.

Nozzle temperatures for nylon should be between 230°C and 260°C and on the bed, you’ll want to go for a maximum of 100°C. There is a risk of warping with this material, so take precautions to reduce this as much as you can.

A kg spool of nylon will cost around $60 – $80; it’s more expensive than many of the other filaments on the market so ensure you’ve tested your design and require these properties.

ASA

ASA is very similar to ABS, with one small difference that makes it more suited to outdoor applications. There’s enhanced UV protection inherent in this filament, so it can withstand stronger sunlight for outdoor prints.

Using a nozzle temperature of between 220°C and 250°C and a bed temperature of around 100°C will yield the best results with this material. It’s relatively simple to print with and the risk of warping is minimal.

As with ABS, adequate ventilation is required when using this material as hazardous fumes can be created during printing.

ASA is relatively inexpensive, with a kg spool costing from $30 – $50.

Polycarbonate

This transparent material is one of the strongest filaments that you can use in your printer. It’s extremely durable and resists scratching; it even resists temperatures up to 110°C. There is some flexibility within this material, which allows it to bend slightly under stress instead of shattering.

As polycarbonate is heat resistant, you’ll require a high nozzle and bed temperature to print with it. The ideal nozzle temperature is between 270°C – 310°C, so check that your printer is able to achieve these temperatures before you buy. Setting the bed temperature to 90°C – 110°C will give the best results.

This material can be somewhat difficult to print with and the print can warp during production. In terms of cost, you can expect to pay around $30 – $60 for a kg spool of polycarbonate.

HIPS (High Impact Polystyrene)

HIPS is very similar to ABS with the primary difference being that HIPS uses Limonene as a solvent. This means that you can use HIPS as a support material which can then easily be dissolved by placing your print in it. This is a good alternative to sanding away regular support material.

It’s a fantastic material to print with if you have a dual-extruder, since using HIPS as the support material makes it extremely easy to create cool prints that would otherwise be impossible.

HIPS, in terms of printing difficulty, is very similar to ABS but is much less likely to warp, and it’s ideal for printing in conjunction with ABS because it has a similar strength and stiffness profile to ABS which means they complement each other well.

Additionally, HIPS and ABS need to be printed around the same temperature, 230°C, and the bed temperature needs to be set to approximately 90-110°C.

You can find a 1Kg Spool of HIPS filament for between $20 and $60.

Flexible Filaments (TPU, TPE, Soft PLA)

If you want to make flexible items, like moulds or rubber seals, then you’ll want to use one of these flexible filaments. When printed, they act almost like rubber and are very durable. If you want to step up production of a model or design, then you can use this material to create a mould and then cast your design in resin, concrete or other material.

TPE is the generic, umbrella term for these materials and stands for thermoplastic elastomers. TPU is the easiest flexible filament to use and you don’t need a heated bed to get started printing either. There’s not a lot of warping to worry about with this filament and it’s simple to snip any stringing off the final product.

TPU prints at 210°C – 230°C and a kg spool will cost between $80 – $100.

Soft PLA can be cheaper to buy but it’s more difficult to work with. As it’s more flexible, it can be more suited to your application but the flexibility of the material can mean that it acts out during the printing process.

Bonus: Resin

So far, we’ve discussed filaments but if you’re using a resin printer, you’ll be topping it up with this material instead. Many users prefer this kind of printer, especially for intricate model figures. The level of detail that these printers can offer is difficult to replicate using a filament printer.

A liter of resin will cost around $80 – $90, depending on the quality and manufacturer. When working with resin, it’s essential to take the proper precautions to protect your skin and lungs. Gloves and face masks should be worn at all times when handling uncured resin.

Resin prints aren’t as prone to warping, but they do require some clean-up and curing after printing. These prints won’t be flexible and you should be aware that once resin is opened and in the tank, you should use it up before it starts to degrade.

I did write an in-depth article comparing the costs of printing with filament and resin, since you don’t only need to take the printing material’s price into account, but a couple other factors as well, so make sure to read that one as well!

Overall filament comparison

| Filament | Nozzle Temperature | Heated Bed | Warping Risk | Ease of Use | Cost |

| PLA | 180°C – 230°C | Not required | Low | Easy | $10 – $25 |

| ABS | 230°C – 250°C | Approx. 100°C | Moderate | Intermediate | $15 – $25 |

| PETG | 230°C – 250°C | Approx. 100°C | Low | Easy | $15 – $20 |

| Nylon | 230°C – 260°C | 80°C – 100°C | Moderate | Intermediate | $50 – $65 |

| ASA | 220°C – 250°C | Approx. 100°C | Low | Intermediate | $30 – $50 |

| Polycarbonate | 270°C – 310°C | 90°C – 110°C | High | Difficult | $30 – $60 |

| HIPS | 230°C – 250°C | Approx. 100°C | Low | Intermediate | $20 – $60 |

| TPE | 210°C – 230°C | Not required | Low | Easy | $80 – $100 |

Reduce the cost by extruding your own filament

Whether you’re a beginner or an expert when it comes to 3D printing, you will have failed prints. With so many pitfalls that can cause your prints to be less than perfect, you may want to investigate recycling your filament. A filastruder will take your failed prints and recycle them back into useable filament – which can save you some cash!

It’s important to note that you shouldn’t mix filament types when recycling, otherwise you’ll get an unpredictable spool of filament with unknown optimum temperatures and properties, making printing with it less than ideal.

Conclusion

Unless you need a specific material for a very specific purpose, like printing models that can be left outdoors in the sun and the rain, then I’d mostly recommend going with PLA simply because how easy it is to print with and how affordable it is.

Most other filaments tend to be more expensive and may also be a lot harder to print with, like ABS.

ASA or PETG can be used to print models that are going to be in contact with sunlight since they are UV resistant. Basically, only get a specific filament if you need to, but in most cases stick to PLA.

Check out our recommended products section

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

Error processing API data.