Recycling used filament spools is an ongoing challenge for 3d hobbyists. This is mostly because not all spools are recyclable. Some spools have a recycling symbol, while spools that do not carry the recycle symbol are used in alternative creative projects or simply thrown away.

Most filament spools are made from polypropylene, a recyclable plastic that can be discarded into normal plastic recycle bins. Empty filament spools can also be recycled by finding alternative uses, such as creating a turntable for printed miniatures, a spool drawer, and using them as wheels in go-karts, among other creative uses.

In order to reduce the creation of plastic spools, you can also buy cardboard spools or recycle your spools by buying only spool-less filament.

You can also opt to recycle your used spools into filament, which can be a cost saver if you print on a larger scale. However, if you want to recycle your spools into filament, you will have to know the spool’s material properties and take into account that they may contain dyes, adhesives, and other additives that will make it virtually impossible to control the quality of the filament.

Companies like Terracycle have stepped up to reduce plastic pollution and have a global presence to deal with 3d printing waste, including used spools. You can either arrange collection or send the empty spools off to them.

Some companies offer incentives to consumers who send their empty spools back for recycling, but this initiative has not gained much traction due to the costs involved.

How to avoid accumulating Plastic Spools over time

To keep plastic pollution in check, it is important for every person to play their part. Used spools contribute a great deal to plastic pollution, even if they are made of biodegradable materials. The amount of time required for the whole biodegradable process is lengthy, and it is compounded by more and more waste being added to the mix.

Being more conscientious about plastic pollution means you have to take a more proactive stance in reducing your carbon footprint. Here are some ways you can make an immediate difference:

Buy cardboard spools

Cardboard spools are a great alternative to plastic ones, but they do present some challenges and, as a result, are not sought after. Cardboard spools tend to flange around the edges even with the internal corrugated support structure. This poses problems during printing as the filament tends to catch on the flanged areas and interferes with the tension in the filament feed process.

Another problem is storage with cardboard buckling under pressure from other spools’ weight packed on top of them. High humidity levels also weaken the structure of cardboard, as does general handling of the spools.

Print the spools

Printing your own spools and buying spool-less filament is another good way to reduce your plastic waste. Printing a dismantlable master-spool offers you the convenience of buying spool-less filament and self-loading the filament onto the master-spool.

This may seem like the answer, but spool-less filament will not always run off the spool with ease. Strands of filament often get pinched into the windings that disrupt the filament flow off the spool.

Filament getting tangled up can cause a lot of frustration and, at times, may even cause the spool to jam. So, although it’s an ingenious concept, it’s not the perfect solution.

Return the Spools to the manufacturer

Returning used spools to the manufactures is not always a practical solution due to cost implications. Some manufacturers introduced incentive-based returns, which essentially means that for every “X” number of returned spools you will get free filament as a reward.

As good as it sounds, most manufacturers stopped doing this since it’s not really financially viable.

Ideas for reutilizing the spools

For hobbyists who have a slow accumulation of empty spools, there are ways to create a new use for what many would consider waste. All you have to do is put your thinking cap on and design a functional use for your growing pile of empty spools.

Think about this as a challenge. You have a pile of empty spools, and you have a 3d printer that can be used to create unique parts if necessary. Put the two together, and you have practical solutions to extend the use of your plastic trash.

You can use them to make Lamps

You can use an Empty Spool to create a simple lamp, and if you really want to take things to the next level you can use a lithophane as the lamp shade!

Now, if you don’t know how to make curved lithophanes, then you can use this tool and simply select “curved” in the settings.

Make a small stool for your kids

The spool size is perfect for making a stool that will suit toddlers and young children. The top can be fitted with memory foam covered in an array of colored waterproof material and mounted onto the spool, which serves as the base of the stool. You can, of course, paint the base any color of your choice or even include a fitting design.

The stool will be sturdy but still light enough for kids to carry it or move it around. The round shape is an added bonus because there will be no sharp corners to cause injury.

Alternatively, you can also put your 3D printer to use and print the structure that will hold the spool stool together.

You can download the design files from Thingiverse (link here). It is compatible with spools that are 60mm high with a 67mm hole.

Create a turntable to showcase your Prints

All you need to do for this great idea is neatly cut off one side of the spool and use a press-fit bearing the size of the core for a tight fit.

Fasten the top of the press bearing to the cut off side of the spool and slip it into place, so you have a spool with a spinning side.

You can then cut out a top for the spool using and glue it into place. Here again, you can color or add designs to have your turntable match its environment. You can print a smaller but thicker base and have your design taper down from the top to the base if you like.

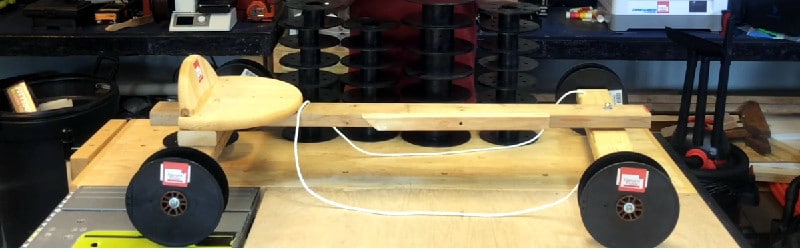

Use them as wheels for toys

Creating wheels for a kid’s go-cart is an easy way to repurpose your empty spools. You will have to drill holes on both ends of the spool to attach the rod that holds the “spool wheels” in place, and away you go. If you want the wheels to last a bit longer, you can include press bearings into them to reduce fiction.

Just check out this amazing go-kart, empty filament spools sure are useful!

Make a Filament Spool Drawer

Making a drawer for small items is a great repurpose concept for the handyman, and it’s a space saver. You will have to measure your spool and print trays that will rotate out from the circle. You can build a column of spools that can independently rotate on a central axis.

This will make storing your small items like nuts and bolts in one place much easier. The drawers will not be transparent, and this may put some people off, but if you are the more organized type, then neatly printed labels for each draw will solve that problem.

There are many other projects that you can repurpose your empty spools for that will help to reduce plastic waste. If you have quite a few spools piling up, you could get creative and make wall clocks or use them to make funky table legs or light fitting.

You can even create a shadow board for your garden tools, or you could create miniature windmills and other decorative gift items.

Check out this awesome design that you can download from Thingiverse (link here)

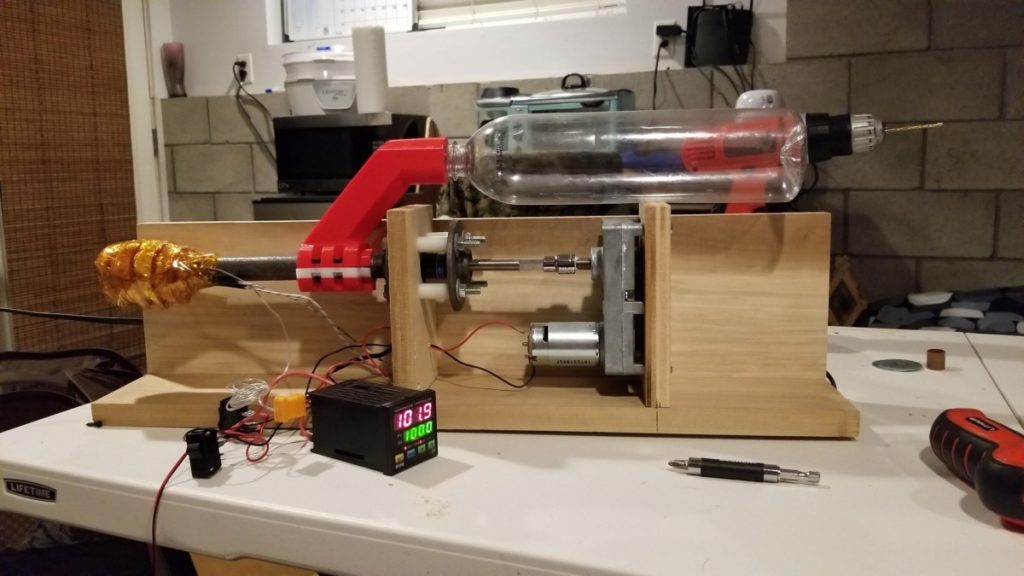

How to recycle filament spools into new filament

Filament spools made from thermoplastics such as ABS can be recycled, but printer temperatures may have to be recalibrated to get the optimum temperatures for successful printing.

First, you will have to cut the used spool into small pieces that are then ground up into small pellets that are compatible with a filament extruder. The pellets are then fed into the extruder, melted, and extruded as filament.

A Filastruder kit is relatively inexpensive and is compatible both with ABS and PLA and will set you back a few hundred dollars.

The kit is easy to assemble and can be used with a Filawinder Kit to wind up the new filament with a guide path and tension sensor to ensure the spool is neatly wound up and will not jam when printing.

If you are doing a lot more recycling, then investing in a Filabot extruder like the Filabot EX6 will be more fitting for your purpose. It is considered a professional extruder and costs in excess of $9000. The price might be a little steep, but it can handle a wider range of materials thanks to the 4-zone temperature control system that can be independently controlled, but it’s definitely not aimed at hobbyist makers.

Conclusion

By now, you probably have a good idea of what you want to do with your empty filament spools.

If you can’t recycle them into new filament or use them for other projects, please consider sending them over to a recycling plant or to any filament manufacturer to avoid unnecessary waste creating.

Have a wonderful day!

Check out our recommended products section

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

Error processing API data.