There is an infinite number of hobbies and interests that can lead you into 3d printing, and one of the most popular is motives is that you might want to print your own miniatures. It does not matter if you want those miniatures for your nightstand or for tabletop games, miniatures have one thing in common: the quality of your miniature’s details is a primary concern.

You might already be somewhat familiar with SLA and FDM, two of the most common 3D printing technologies. If you don’t know what they are and what differentiates them do not worry, we will explain both methods in detail. By doing so, we will also discover if FDM or SLA is more suitable for printing miniatures.

An SLA printer yields finer details than the ones you can expect to obtain from an FDM printer. In cases like miniatures, where accuracy is a major concern, SLA printers are a better option. Nonetheless, having an FDM machine can be an advantage because it tends to be more price and cost-efficient. Additionally, FDM printers usually have a greater build plate, allowing the user to print a broader range of objects.

Let’s break down every major concern that you might have when it comes to choosing between both technologies. We will compare them in terms of output quality, the versatility of use, materials cost, and the cost of acquiring one.

Comparrison Table: FDM (filament) vs SLA (resin)

| FDM | SLA | |

| Printing Speed | Faster | Slower |

| Cost of printer | Cheaper | More Expensive |

| Materials | Cheaper | More Expensive |

| Buildplate | Bigger Surface | Smaller Surface |

| Materials Variety | Wide | Wide |

| Resolution | Much Lower | Much Higher |

| Precision | Little Lower | Little Higher |

| Handling | Easy | Difficult |

| Postprocessing | May sanding or acetone | Already Smooth |

| Min Layer Height | 0.1mm | 0.05mm |

| Supports (angle) | Greater than 45° | Always requires supports |

| Supports (bridges) | Greater than 10mm | Not required |

| Min. wall width | 0.8mm | 0.5mm |

Output quality of SLA and FDM

While FDM printers work by depositing lines of molten plastic on top of each other, SLA machines cure liquid resin by means of a very precise laser. This allows SLA printers to generally obtain higher quality prints and in a more reliable and repeatable way.

In a nutshell, when it comes down to the overall quality and reliability of your prints, SLA is the clear winner.

It is also useful to discuss the main parameters that relate to overall quality in order to further expand on this important topic.

Layer Height

There are multiple ways by which we could talk about quality and detail. For simplicity, let us start with layer height since the possibility to print miniatures with smaller layer heights translates directly into finer details, therefore we should always keep this parameter in mind.

With popular high-quality hobby FDM printers like the Ultimaker 2 or the Prusa I3, we can expect to get great prints with layer heights as low as 0.1mm. Although this layer height is impressive, SLA printers can easily go as low as 0.025mm. Simply put, SLA printers can print up to 4 times smaller layer heights than FDM printers, or even lower.

Accuracy, precision and tolerance for FDM and SLA

When it comes to measuring quality, it is also incredibly useful to differentiate these three terms. Let us start by quickly defining our three concepts so that we can proceed to check which one scores higher on each.

- Accuracy: by this, we try to define how close our print is to the real expected value. When in the 3d printing realm, the true value is none other than the dimensions that are specified on the CAD files. We can take a caliper and measure our print in different sections and compare them with their respective digital counterparts. The closer the measures are to the expected value, the more accurate our printer is.

- Precision: this measure is closely related to accuracy. It answers how similar different prints of the same model will be. In other words, if we print the same model a hundred times, the precision tells us the degree of uniformity that we expect within our batch. In statistical terms, it can be interpreted as the standard deviation.

- Tolerance: tolerance is defined by the user and consists of a threshold of acceptable precision and accuracy.

You can think of accuracy and precision in terms of shooting arrows at a target. If your arrows land close to the target, you will be recognized in town as an accurate bowman. If you want to be precise, you do not need to shoot near the target, but the arrows have to be close to each other. It would be technically accurate to depict Wilhelm Tell as both an accurate and precise archer.

Getting back to our matter at hand, let’s use these newly acquired definitions to compare SLA and FDM printers.

SLA printers are always going to be more accurate than FDM printers since they are able to print in lower resolutions. The optical spot size of an SLA machine is smaller than the nozzle diameter of the FDM counterpart. Additionally, during printing, a lot less force is applied to the object when using laser technology.

In fact, the main reason why people choose SLA printers is that they achieve finer details in their models. So, if your only determinant is the level of details that you can expect your miniatures to have, then definitely go for an SLA printer.

Keep in mind that FDM printers can also yield awesome miniatures, especially if you decide to install a nozzle with a smaller diameter.

Take a look at the following miniature printed using both technologies.

Yes, you may notice that both prints have been heavily post-processed and painted, but it also shows that you can get exceptional results with both machines.

Additionally, it is a non-trivial fact that the object on the left was produced with an Ender 3 FDM printer which usually goes for about $250. On the other hand, the Form 3 SLA printer used for the miniature on the right will set you back $3.500.

If your heart skipped a beat while reading that price tag, I should also mention that SLA printers are getting more affordable each year. A fine example of this is the Anycubic Photon.

Can FDM printers print miniatures?

Although not as detailed as SLA printers, FDM machines are perfectly capable of yielding great miniatures. All popular slicers like Cura, Simplify3D, or PrusaSlicer come with out-of-the-box profiles for different print quality.

If you want to take your miniatures to the limit, reduce the speed, use a smaller layer height, and try to print using slightly lower temperatures (without clogging your nozzle). To further enhance your objects, you can choose to install a 0.2mm diameter nozzle (assuming that you have a standard 0.4mm one).

Granted, your miniature will require some serious printing time, but the results are going to be incredibly rewarding.

Best filament for printing miniatures

This section completely assumes that you decided to go for an FDM printer and that you want to know which filament is best for this use case. The most popular filaments are polylactic acid (PLA) and acrylonitrile butadiene styrene, better known as ABS.

Briefly, PLA is better for printing miniatures in most cases because of how easy it is to print with since it doesn’t require the use of a heated bed or a high level of expertise.

ABS, on the other hand, while it can yield higher levels of detail, but requires more expertise to be printed properly and it generally suffers from warping.

Also keep in mind that if you want to print your miniatures in ABS, your printer will need to have a heated bed and an enclosure. Although these tend to be a bit pricier, it is also possible to build your own enclosure around your open printer.

Another alternative would be to get a generic enclosure that fits most printers, such as this one by Creality which not only works great but is also non-flammable, since this is a very affordable way of being able to print with ABS.

Heated beds are very common nowadays and you can expect most printers to come with one already out of the box. I definitely encourage everyone who is about to buy a printer to choose one that has a heated bed or to purchase an additional enclosure like the one I just linked.

I will not go into further detail, but if you want the full breakdown, you can check my article comparing filaments for miniatures. There, I also talk about post-processing techniques that you can easily pick up and take your models to the next level.

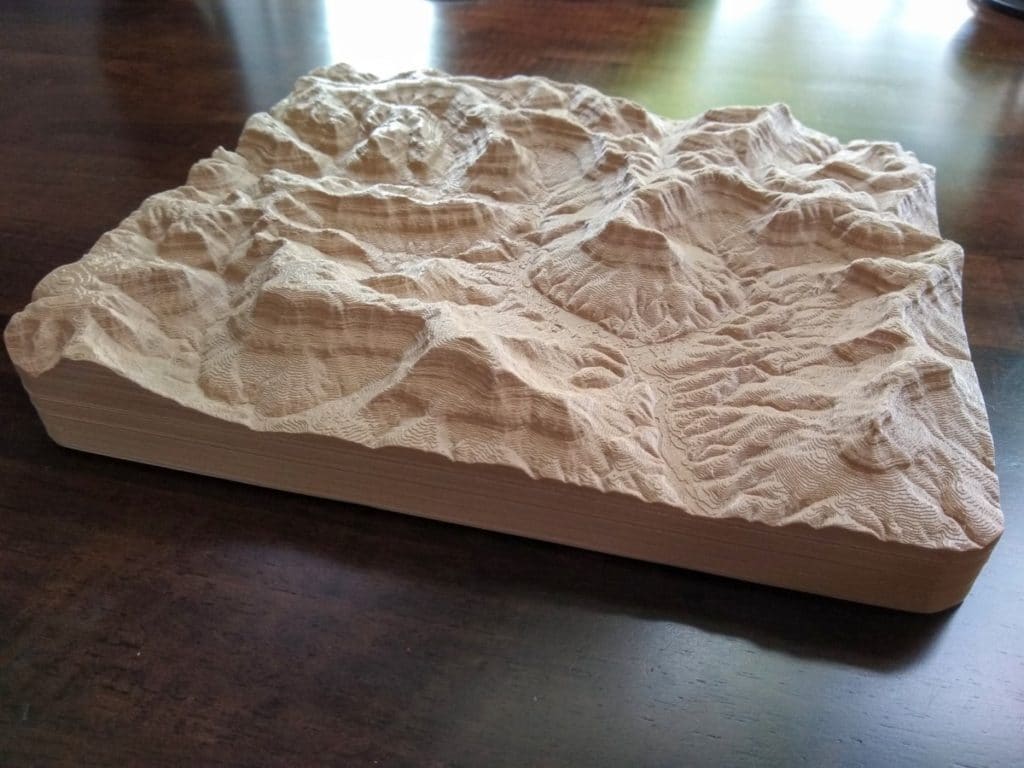

Filament vs Resin for printing terrains

Your interest in 3D printing might have started because you wanted to create your own miniatures, but you should always keep in mind that you might want to use it for other purposes in the future. You may even end up using your printer for the complete opposite purpose, which I guess would be to print a statue instead of miniatures.

It is not necessary to imagine such a ridiculous scenario. In fact, there is a non zero probability that your miniatures will also need some kind of terrain. Terrains, by definition, have a tendency to be a lot bigger and will thus consume a lot more material than the miniatures. Additionally, when producing larger objects, printing time may become an issue.

Although SLA printers can print everything, they are not the go-to option for printing terrains. Resin printers are more expensive, take more time to print, and have a smaller printing surface.

In cases where the level of details is not a primary concern, you should probably print with an FDM machine.

Cost of filament vs resin

Both filaments and resins come in different types and qualities, so we should take these numbers with a grain of salt. Nonetheless, the qualitative conclusion is that resin is more expensive than filament.

Let us proceed with an example. While a 1kg of PLA usually costs about $15-$20, a liter of resin will set you back around $50. You may have noticed that, although we are using the metric system, we are mixing units. It is quite dubious to compare one kg of material with one liter of another.

In order to compare apples to apples, we will take an object as an example. The most obvious file that comes to mind is the useless 3DBenchy*. It is widely used by the community (and myself) to troubleshoot 3d printers. Take a look at a bench in all of its glory:

*: 3DBenchy is so popular that it even has its own website.

I printed both of them on an FDM printer, but the small one is the regular size.

Using settings that are not out of the ordinary, a 3DBenchy (with 40% infill) will consume 13 grams of filament, while its resin counterpart is going to need 20mL. Let us now do some sophisticated arithmetic.

With 1kg of PLA, we will be able to print almost 77 3DBenchys, while 1litre of resin will yield 50 of them. In other words, a resin 3DBenchy costs roughly $1, in contrast to the $0.20 that an FDM one requires.

Of course, these numbers are just rough approximations that depend heavily on the settings of the slicer. Despite that, the enormous difference is so clear that we can safely conclude that resin is obviously more expensive than filament.

Conclusion

Having covered the main differences, as well as pros and cons of both types of technology, it is safe to say that, if you are only going to have one printer, you should probably choose to go the FDM route.

Although it will not yield perfectly detailed miniatures as an SLA printer would, it will still output amazing results if tuned properly for this purpose. Additionally, having an FDM printer will give you more versatility regarding the type and range of objects that you will be able to print in a time and cost-effective way.

I would recommend going with the Ender 3 since it’s incredibly affordable and prints really well, even better than most high-end printers (It has its fair share of drawbacks, but printing quality is not one of them).

Check out our recommended products section

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

Error processing API data.