As a newbie to 3D printing, this is the question that may have been bothering you for months. You’re always on the lookout for materials to print your models with and have tried polylactic acid (PLA), Acrylonitrile butadiene styrene (ABS), Architectural Acrylic (aka shiny glue), and more.

But you keep wondering, how long does 1 kg of filament last? How many meters of filament are there in a 1kg spool? How much filament do you need for an average Print? How many models can you print with a 1Kg spool? How can you make Filament last longer? And what factors can affect it?

Luckily, in the following article, I will answer all of these questions.

| Filament Weight | Density | Thickness | Length | Price |

|---|---|---|---|---|

| 1Kg | 1.25g/cm3 | 1.75mm | 330m/1080ft | $20-30 |

| 300mm | 110m/360ft | |||

| 3Kg | 1.25g/cm3 | 1.75mm | 990m/3240ft | $55-70 |

| 300mm | 330m/1080ft | |||

| 5Kg | 1.25g/cm3 | 1.75mm | 1650m/5400ft | $90-110 |

| 300mm | 550m/1800ft |

Now, before we start, let’s keep in mind that the filaments for standard desktop FDM 3D printers are usually available in 1kg, 3kg, and 5kg rolls called “Spool”.

A standard 1kg filament spool costs around 20-30 US dollars. But it can cost significantly more in countries with high import taxes.

Now let’s answer one question before we get into the post itself: Why are these filament spools sold in Kgs instead of Meters/Feet? Well, the answer is simple, the length of filament inside a spool depends on two factors, i.e. the density of the material and the cross-sectional area, or diameter of the filament.

Let me show you how to calculate the length of a 1kg filament spool with an example. Suppose you have bought a PLA filament spool of 1kg which has a density of 1.24g/cm3 with 1.75mm of diameter. It will contain 252.13 meters of filament (there are many calculators available on the internet that can perform these calculations for you). If the price of the spool was $25 then it would have cost 9.9 cents per meter.

Now, without any further ado, let’s get into the post itself!

How much filament do you need for an average Print?

Or in other words, how many times can I print a single object with a 1kg spool?

The easiest way to answer is to calculate (in grams) the weight of the object (including its supports, brims, rafts, and skirts) you are about to print because you can only print exactly 1kg of material from a 1kg spool.

Let’s assume that the custom iPhone case you are printing and selling on the internet weighs 11.8 grams. Then you can print 1000/11.8 = 84 iPhone cases if you utilize all of the filament without wasting it.

Similarly, let’s suppose the custom necklace you are making costs 5 grams then you can print 1000/5 = 500 necklaces. This will only help those people who wish to print the same object multiple times to either gift it to their friends and family or sell it online.

Random Tip: If you are printing multiple objects of the same size, it is better to print them as multiple parts and then assemble them.

For example, if you want to print earring shaped pendants (1.25 inches in diameter circle), don’t print one ring with a wall thickness of 0.8 mm, because when you turn it sideways or drop it, its shape is going to be distorted; instead, design each earring as a pair of circles with a shared hole on the rim and join them

How to check the amount of filament the print will need in the slicer software?

Slicing softwares tell you the estimated print time when you load an object’s design file (although it is never accurate), they also tell you how much filament will be needed in grams to print the object (this is usually quite accurate).

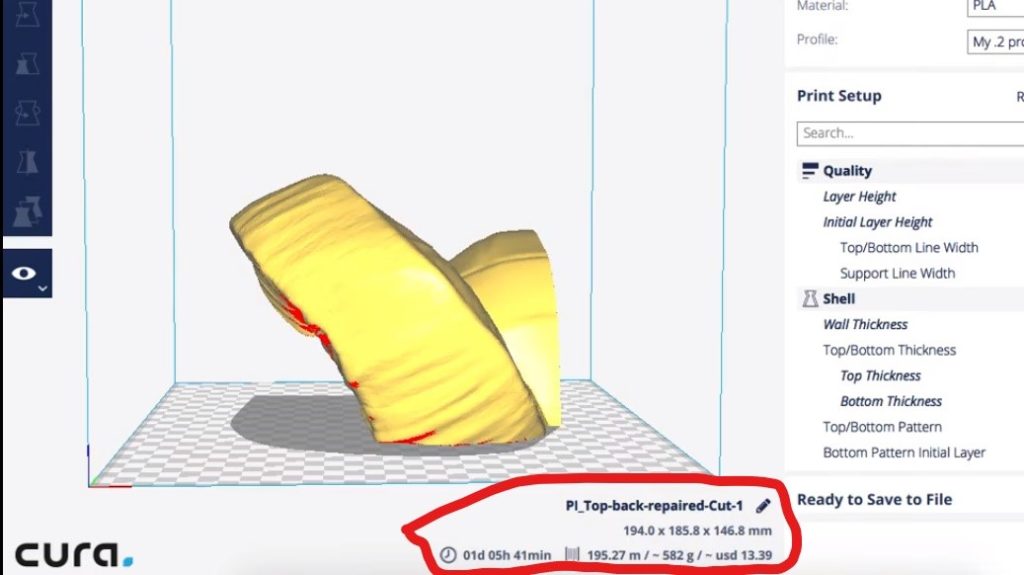

In the figure below, you can see that Cura is telling me that, to print my object it will consume 582 grams which is more than half a kg. For me, it is always a red flag, and I avoid printing objects that need anywhere near 500 grams.

The reason is that it will take a lot of time usually 1 or 2 days (if you have a decent quality printer it won’t be an issue to start a print and leave the printer to finish it on its own) but the problem is that the print may need you to change spools midway and a lot can go wrong while doing this.

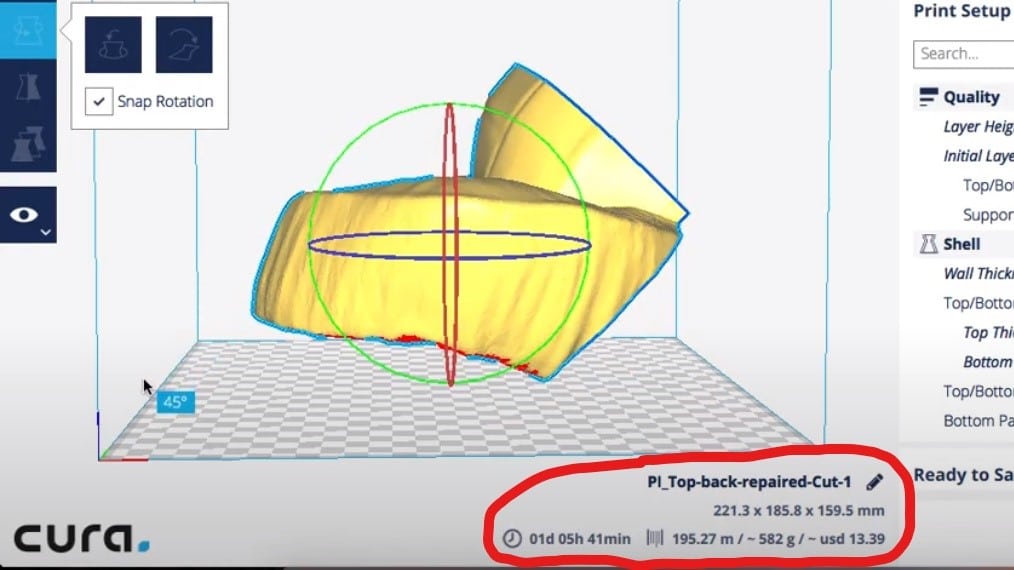

I’m usually able to overcome such issues by making a few small changes in my design or sometimes by even changing the orientation of the object in the slicing software. As you can see below, when rotating the object horizontally, the number of grams needed to print this object dropped from 582 grams to 452 grams.

By making such a small adjustment, I was able to save almost 130 grams! You must be wondering how is it possible.

Well, it is simple, by printing the object horizontally instead of vertically, it will need a lot less support. I did simple calculations, I had bought this 1kg spool for $30, and by making this small adjustment, I was able to save $4 and that’s more than 1/10th of what I paid for the spool.

How can you make Filament last longer?

There are four ways you can do that, so let’s discuss each of them in fine detail.

- Reduce the Size of the 3D Models

- Reduce the use of Brims, Rafts, and Skirts

- Reduce the use of Supports (if at all possible)

- Reduce the Infill

1) Reduce the Size of the 3D Models

Every time makers are printing something huge without carefully thinking why they need to print it that big there is a gradual decrease in details when you increase the size, but there will be a ten folds increase in material cost, time consumption, and many other things as well which make it hard to continue 3D printing larger objects

Either don’t print as often or don’t print large size object. There is no point in printing large objects, smaller ones also look just as good, if not cooler. If you think that people get impressed by seeing large-sized prints, don’t forget that they also get impressed by seeing finer intricate details on smaller objects as well.

I will say it again, there is no point in printing large objects and they should only be printed when you need to print a 1:1 prototype or part. Therefore, try to control the temptations and always ask yourself, do I really to print it this big?

2) Reduce the use of Brims, Rafts, and Skirts

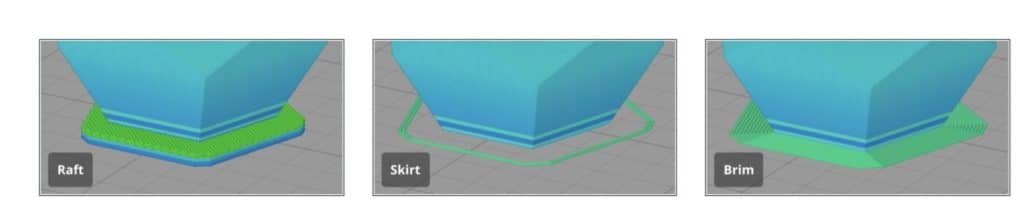

A Skirt is a routine of filament extrusion that you can set in your slicer to perform right before the start of your printing job. It consists of an outline that surrounds your print and is aimed at ensuring that the extruder is properly primed and that a constant flow of filament is extruded when the object starts printing.

A skirt also helps the user in determining if the machine is well-calibrated. If you are not satisfied with the quality of the lines being placed on the build plate, you can adjust the bed before it affects your object.

A brim consists of a skirt that is attached to your model. It is useful for enlarging the surface of the first layer, thus improving the adhesion of the model to the build plate. It is attached to the model is also its main disadvantage, since you have to be careful not to damage the model when removing the brim.

Finally, the raft is a latticework that gets printed beneath the object. By doing so, your model will only be in contact with the raft and not with the build plate. This feature is mainly used as a way to avoid warping when printing with ABS. It takes some time to print and consumes a nontrivial amount of filament, so only use it when necessary.

The main advantage of skirts is that they don’t consume as much filament as rafts and brims. On the other hand, and in contrast to brims and rafts, skirts do not improve your layer adhesion. Since they are not attached to the object, they do not make the bottom surface larger.

To be clear, I’m not saying that you should avoid using these features at all costs. In fact, I always use a skirt of 3 lines on my default profile. Also, when I’m concerned about the object getting loose because it only has a small contact surface, I don’t double guess whether to add or not a brim.

The main takeout of this recommendation is that you should properly choose when to use a raft, a skirt, or a brim based on the specific object you are about to print.

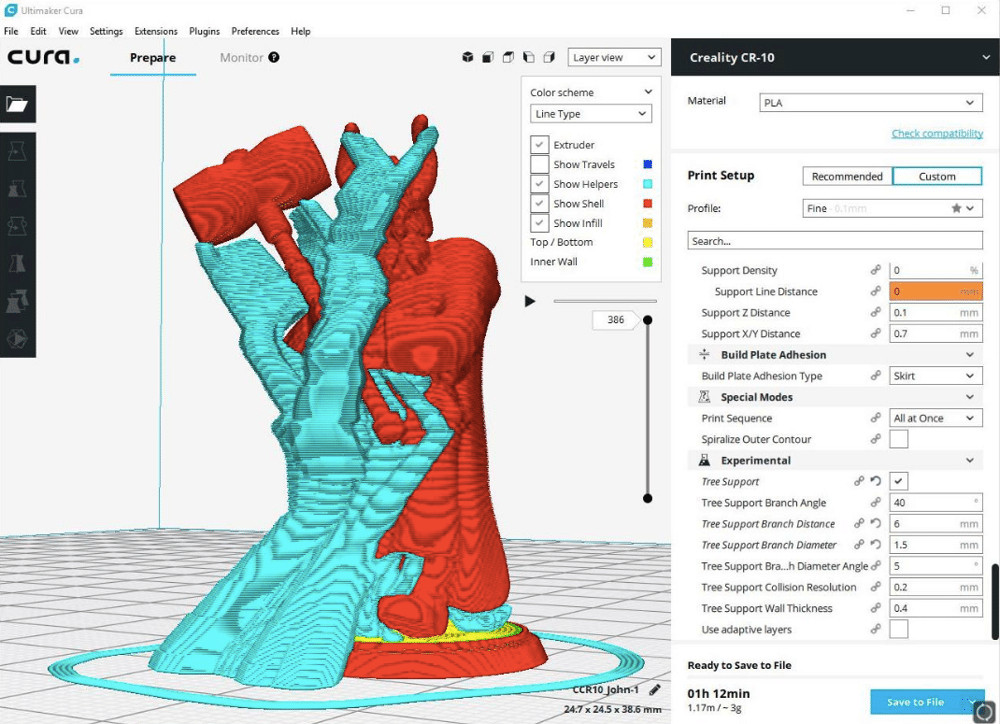

3) Reduce the use of Supports (if at all possible)

Those new to 3D printing often fail to recognize the importance of supports. They serve as a foundation for parts that are difficult or impossible to print otherwise and can even improve the quality of an advanced print.

Not everyone can design awesome 3D designs and manage to save on filament costs; it’s an acquired skill that takes time and experience to master.

A lot of 3D models on Thingiverse have too many supports because the Thingiverse search hardly takes into account how much printing material is wasted on them. But there is no reason why you should not make simple adjustments that can save you time and money.

It’s not even that difficult, as you saw in the example above, I was able to save $4 worth of filament by just rotating my design from vertical layout to horizontal layout in the slicing software.

Slic3r and other Slicing software allow you to customize the thickness of the support material. This is a very effective method to reduce how much material is needed, or in some cases prevent you from needing support material entirely.

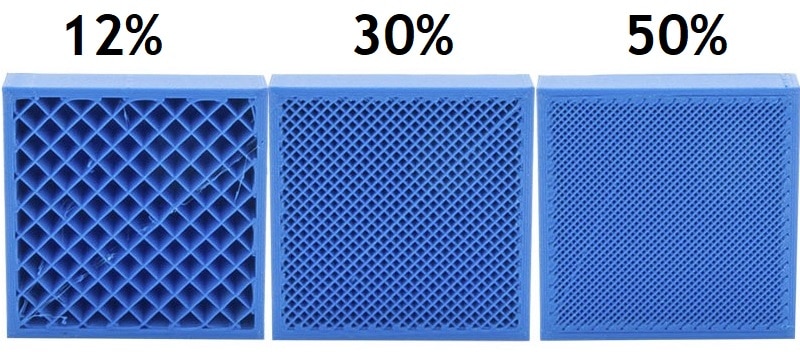

4) Reduce the Infill

Infill is the amount of material used inside a model. When you select the infill percentage, this is how much of that percentage of material will fill in the gaps between the walls outside the print.

While it’s technically possible to print with 100% infill, we did find that there are some benefits to printing with less. For starters, any parts that need support – tools or other objects with overhanging pieces – will often print better at lower infills. When it comes to infill percentages, many experts advise against using anything over 50%. Some even encourage you to stick with 20% infill and below.

But it’s no secret that low-cost printers have trouble printing high-quality parts. With a large amount of infill, you’ll get more strength and durability out of your machine but you’ll also sacrifice overall print time.

For most applications, percentages above 50% are not necessary. However, if you are looking for strength and durability, a 60%-infill build should be enough to support your needs.

These recommendations are made to ensure that you get a strong and stable print without adding too much weight. This is particularly important when you’re printing large models, as they typically need quite a bit of infill to stay sturdy.

The main problem when trying to decide what infill pattern to use, but the honeycomb and hexagon patterns are usually good picks to do this.

The honeycomb-shaped infill is the fastest and least material-intensive pattern.

To make a hollow clear figure, we can use infill to create space while keeping a solid outer shell. Essentially the honeycomb infill is the strongest and a good choice if strength is important for your model.

For miniatures or models where strength may not matter much, the hexagonal infill pattern might be the best one to go with.

Check out our recommended products section

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

Error processing API data.