If you have been introduced to the 3D printing world fairly recently, you already know about all the most relevant slicers. You may have also noticed that among them, there is a slicer that stands out because of its price tag.

Considering that most free and open-source slicers available today have made incredible advances and improvements in the last couple of years, it may not be as obvious if it is convenient to pay for a Simplify3D license.

Therefore, in this article, we will focus on comparing the most popular slicers, their pros and cons, and answer: is it still worth it to buy a Simplify3D license?

Simplify3D still has some advantages over the remaining slicers, with the most important one being the possibility to work with multiple processes. Cura and PrusaSlicer have come a long way and are more than enough for most use cases, but if you run a 3D printing shop, it is arguably still worth paying for a Simplify3D License.

I will treat every aspect in detail throughout the article, but here is a quick summary of the current state of Simplify3D compared to Cura and PrusaSlic3r:

| Simplify3D | Cura | PrusaSlic3r | |

| Cost | $149 | $0 | $0 |

| Discount | -25% for Makerspaces -25% for Robotics Teams -25% for University students and faculty | Free | Free |

| Free Updates | 1 year | Always | Always |

| Operating Systems | -Windows -MacOS -Linux | -Windows -MacOS -Linux | -Windows -MacOS -Linux |

| Supported printing technologies | FDM | FDM | FDM and SLA |

| File Support (STL/OBJ/AMF/3MF) | Yes | Yes | Yes |

| Advantages | –Processes -Sequential prints -Faster slicing -Manual supports | Most frequent updates –Plug-ins -Experimental settings | -Bridge Detection –Conditional If-statements |

| Disadvantages | –Expensive for hobbyists -Slow update cycle | ||

| Website | Link | Link | Link |

Lets cover each item individually, shall we?

Simplify3d advantages

A few years ago, it was more than clear that Simplify3D was the best slicer on the market. We just knew it as a fact and there was no debate about it. As years have gone by a few popular slicers, like Ultimaker’s Cura or PrusaSlic3r have made incredible improvements and most advantages of S3D do not hold true anymore.

Obviously, in order to stay competitive and charge a hefty sum of cash for software with good free alternatives, Simplify3D still offers a few features that can be important for a specific niche in the 3D printing community.

Among the advantages that Simplify3D still has over its competition, we should mention the superiority in slicing speed, manual placement of supports, and the option to have different processes for the same printing job.

Other articles older than this one may also list a few advantages that were true in the past but not anymore. I will also list those advantages that Simplify3D had in the past in order to let you know that you should now ignore them!

Slicer speed

Simplify3D still delivers G-Code in record times when compared to what the same STL file with similar settings takes to process on PrusaSlicer or Cura.

I personally performed a few tests a couple months ago and confirmed that S3D was nearly three times faster than Cura at slicing the same model with almost the same settings. Having said that, I have to admit that I am able to waste a few seconds every now and then in order to preserve $149.

Taking into account how fast computers are nowadays and how little time it takes to slice most objects that I tend to print, most hobbyists probably will not base their decision on this almost trivial advantage.

In summary, Simplify3D can slice objects faster than Cura or PrusaSlic3r but it is not a relevant advantage for most users.

Manual placing of supports

I cannot think of any modern slicer that does not create automatic supports for overhangs. It is nowadays a necessary feature and its absence would render any program useless.

As is the case, most slicers allow the user to set the maximum overhang angle, support pattern, and density. Simplify3D, Cura and PrusaSlic3r are obviously not the exception.

Nonetheless, it is in the manual placing of supports where Simplify3D still shines brighter than the rest. By using the “Manual Placement” tool, you can add or remove entire support sections in an almost automagical flow. I am still surprised about how easy and intuitive it is.

The good news for us hobbyists on a budget is that Cura’s most recent version already includes a somewhat similar feature, and the guys at Ultimaker choose to name in “Support Blocker”. PrusaSlic3r also added similar features.

Although Cura and PrusaSlic3r also offer manual support setting tools, Simplify3D’s manual placement is still superior and more intuitive to use.

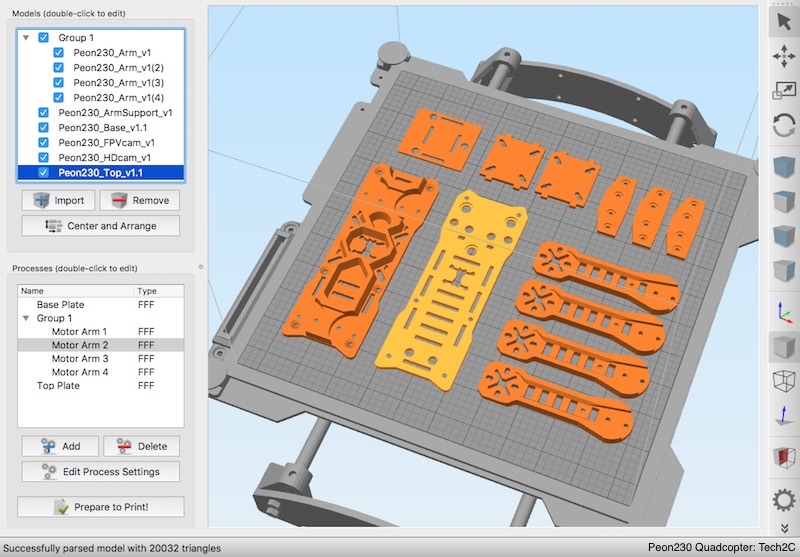

Processes

If you never used the Simplify3D before, you may not even know what processes are! S3D allows users to set different settings for different objects on the build plate, and to set different parameters for different object sections. For example, you can set different layer heights for the same object.

This may seem trivial at first, but it is a very powerful feature whose value cannot be overstated. Imagine printing a huge print that is overall very simple but has a few incredibly detailed sections. In Cura, you can set a coarse layer height and obtain a fast print at the expense of losing those small details. You could also choose to print the entire object at a very small layer height and end up with an awesome print that took years to finish.

Simplify3D offers a third option in accordance to the famous meme: Why not both!

In S3D we could set a layer height of 0.25mm for most of the print and lower it to 0.1mm or even 0.05mm only for those layers where detail is of the essence. If you already sliced a few objects and printed a few files, you have to admit that this option is just great*.

*PrusaSlic3r recently introduced this options and I use it arguably too much.

Update: Cura now also offers a similar feature that allows you to adjust specific parameters in different parts of the same print.

Sequential printing

This feature should technically be covered in the processes section, but I choose to treat it separately because of the subjective importance that I assign to this awesome option!

Simplify3D is the only slicer that, if positioned properly on the build plate, lets us print multiple objects in a sequence instead of in parallel.

Imagine the improbable scenario in which a client asks you to print 20 Benchy’s for tomorrow. Being the reckless rogue printer that you surely are, you copy Benchy 19 times, start the print and go to sleep.

If everything turns out fine, you will wake up with 20 nice-looking boats. It could also happen that, in mid-print, a single layer shift occurred. Congratulations, you are the proud owner of 20 failed prints, a missed deadline, and a disappointed client.

Just imagining that scenario probably gave you goosebumps, so instead, you chose to stay up all night and start 20 prints in order to make sure you can deliver.

Simplify3D lets you place multiple objects on the build plate and, if properly placed on the surface, the exported G-Code will make your printer print them one at a time. Hence, the term sequentially!

If, god forbid, a layer shift or some other nasty thing happens during the print, it will most probably only affect one of your objects instead of the entire batch.

In our previous ludicrous example, we would place 24 Benchy’s and go to sleep. If you own a regular printer like myself, you will wake up with about 21 successes and 3 failures. You not only met the deadline, but you also get to keep an entire Benchy to yourself*.

*I checked the math. I think (guess) I’ve got it right.

Another major argument in favor of sequential printing is that it eliminates that ugly stringing caused when moving from one model to the next.

I think I went on too long with this sole feature, so here is the “too long, didn’t read” snippet:

Simplify3D allows you to print multiple objects sequentially instead of in parallel like we are used to. By doing so, we diversify the risk of failure and, instead of having all our objects on the build plate be a binary success or failure, we will get almost all right (most of the time). It also gets rid of the stringing caused when moving between the parts.

Disadvantage: Plugins

As you may be aware, Cura is an open-source software maintained by Ultimaker and an awesome community of developers. In contrast, Simplify3D is a close development lead by a single company. Both models have their advantages and disadvantages.

Lets avoid getting into the open-source debate and just talk about the consequences. Because Cura is open source, it has lots of very useful plugins that you can add or remove from your installation. This is, simply put, awesome!

Just to give you an example: if you hate converting imperial units into their metric counterparts, you can simply install the “Barbarian Units” plugin and never face that problem again. Also, if you are too lazy to position an object in such a way to minimize the need for support, just install “Auto-Orientation”.

You get the gist. Simplify3D on the other hand does not have a community of developers that add their custom snippets and scripts to serve specific needs.

Ultimaker’s Cura has more than 280 contributors, and you can also become one by cloning the repo and solving tickets: Check out their repo!

PrusaSlicer also has a beautiful community of more than 280 coders. Seven of them work at Prusa. Check out their Git Repo.

Does simplify3d improve printing quality?

It used to be the case a few years ago that by simply using Simplify3D you would get better-looking pieces. I guess that the engine that converted STL files into G-Code was more sophisticated and powerful.

As of today, it is really up to debate if this assessment still holds true. Some folks still say that Simplify3D yields better results than Cura or PrusaSlicer. The remaining nerds will state that a fine-tuned open-source slicer will yield identical results.

I personally do not have a strong opinion on this topic but, having heard from both parties, we can conclude that Simplify3D slices better than or equally as good as any other slicer in the market. To date, there is no one who is willing to say that Simplify3D outputs worse G-Code.

Is simplify3d a one-time purchase?

Simplify is indeed a one-time purchase that does not require a periodical renewal. The license also includes one year of free upgrades in order for the purchaser to stay up to date with the latest versions.

This may seem good at first, but one year of free upgrades is actually one major drawback.

The 3D printing world still is a new and dynamic market with exponential improvements and radical paradigm changes. In this space, it is a clear necessity to have an updated slicer installed on your computer.

While Cura and PrusaSlicer will let you benefit from their constant updates, Simplify3D only lets you do that for a single year. After that, you will hold software that gets more outdated every month.

It is strictly true: Simplify3D does not require periodic payments. Nonetheless, because of what I have said before, the company is implicitly charging a yearly subscription for those who do not want to be left behind technology-wise.

I should also mention that you could choose to try the software for two weeks and ask for a total refund if you do not think the software is worth the price. That is actually a nice offer because it is more than enough to make an educated decision.

It is also worth mentioning that you only need one license per computer and not per printer. Technically, you could run an entire printing farm with just one license.

Conclusion

If you are a newcomer to the 3D printing world, most free and open-source slicers are excellent and will be more than enough for most use cases. More probable than not, you will not feel impaired because you do not have a Simplify3D license.

Simplify3D still has some advantages over the remaining slicers and the most important one is the possibility to work with multiple processes. You can set different parameters for different objects on the build plate and even different layer heights to the same object. This feature alone is more than enough to buy a license if you are in charge of a printing shop.

Check out our recommended products section

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

Error processing API data.