Tree supports are essential when printing complex 3D models, and if you’re using Cura, then you should know how to work with tree supports and what settings to use for optimal printing quality.

In this article, I will provide you with a basic overview of what supports are, and more specifically, what tree supports are, their pros & cons, and how to use them in Cura.

So, without further ado, let’s get started.

Basics of Supports in 3D Printing

FDM and FFF printers work by printing layers of thermoplastic and each new layer has to go on top of the previous one, and in this method the bottom layer is supporting the newly printed one.

This all works very well until a piece needs to be printed that doesn’t have any type of support underneath it, and that’s where supports-, and more specifically for the sake of this article, tree supports come in.

Supports are structures that are not part of the print itself that let you deal with overhangs and bridges with ease, with the only downside being that you end up consuming more material and having to do extra work to remove them later on once the print is finished.

Why are supports needed and when should you use them?

Before we go into the nitty-gritty of why supports are needed and when they should be put into use in 3D printing, we first need to establish what supports are in general.

Support systems in 3D printing are structures used to hold certain 3D models in place while printing which, once the print has finished, are detached from the model.

It’s important to note that not all 3D models need a support system, but rather those that have physical tilts of 45° and above.

Now that you have a better idea of what support systems in 3D printing are, let us examine how to know whether or not you need to use them or not in your prints.

When should you use supports in 3D printing?

The first thing you have to consider when deciding whether or not to use a support system has to do mostly with the angle of the overhangs, as well as the use of bridges.

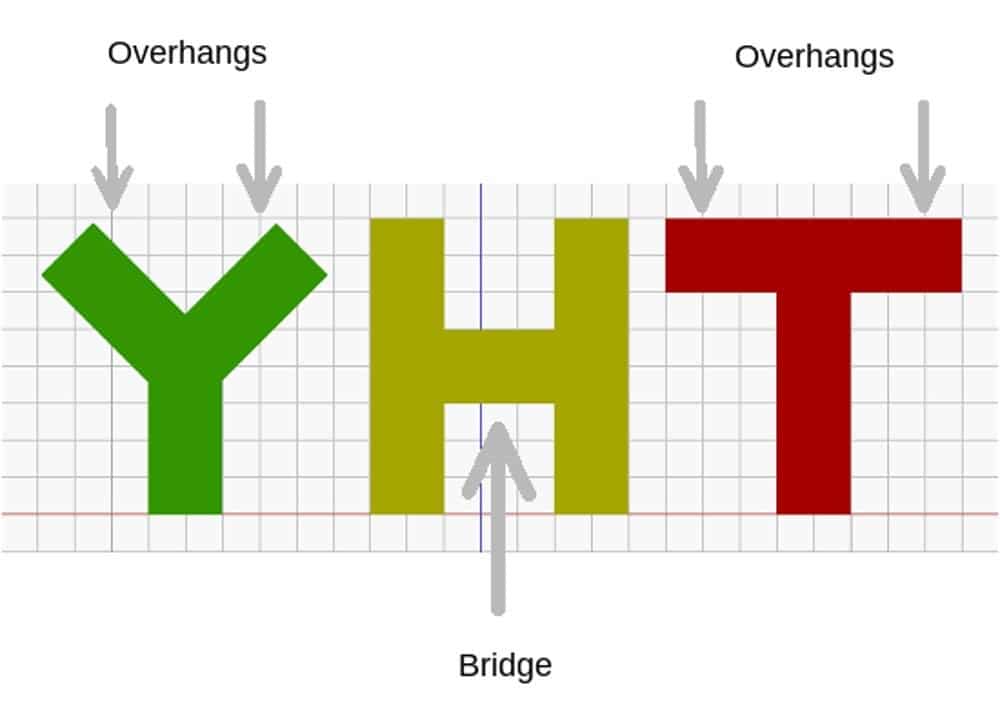

Overhangs are parts of the print that need to be printed in the air without having any structure underneath to hold/support them.

A clear example would be if you’re printing the letter “T” vertically, since there no structure supporting the horizontal parts (arms) of the print, and in this case, to have a successful print, additional supports will be needed.

Something similar happens with Bridges, since these are just horizontal structures that are connected to two vertical lines, like a model of the letter “H”, for example.

Overhangs and bridges are usually measured in degrees through the Z-axis above the overhang:

Structure “T” for example, has an overhang of 90° while the structure “Y” has an overhang of 45°.

Now, when asking yourself if a particular model needs a support system, you should consider this; If a particular model has immense and multiple overhangs of 45° and above, you will most likely need a support system, and if the angle is closer to 90°, you will absolutely need a support system for printing.

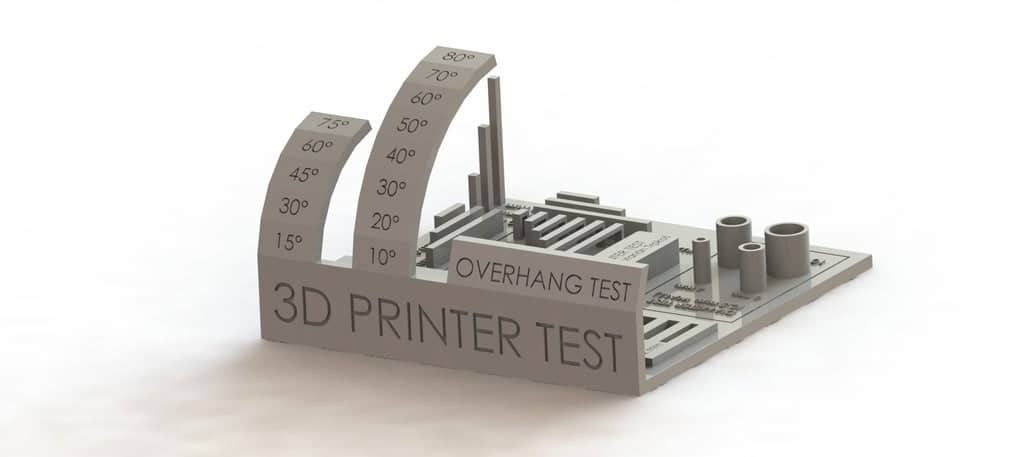

One thing you could do is check how well your specific printer does at dealing with this issue since not all 3D printers are equal and the results may vary between them.

Basically, some models with a 45° overhang may look good on some printers even without a support system, while on others it may be virtually impossible to print them correctly.

What you can do is test your 3D printer by printing an overhang test which will show you exactly at what angle your printer can no longer print properly, and this should give you an accurate representation of when to use supports and when you may print without them; If the print fails at 60°, then you know that supports will be absolutely necessary from that point on.

Another thing you might want to consider is adjusting the printing speed:

It is a general rule of thumb in 3D printing that slower printing speeds result in more smooth and detailed models, but this is not the case with support systems and overhangs; The faster the printing speed, the better the overhangs and bridges turn out on your prints.

What does this mean? It simply means that if you prefer slower printing speeds, you will probably need to rely on some sort of support system because there is not enough speed to avoid wobbles around the overhangs and bridges.

There are many 3D support systems available today, but the one we’ll be focusing on today are tree supports since these are the ones that generally work the best.

Tree Supports

Once you made certain that a support system will be needed, then it’s time to figure out what type of printing support you should use since there are a couple to choose from, like Tree Supports, Linear Supports, Dissolvable Supports, etc.

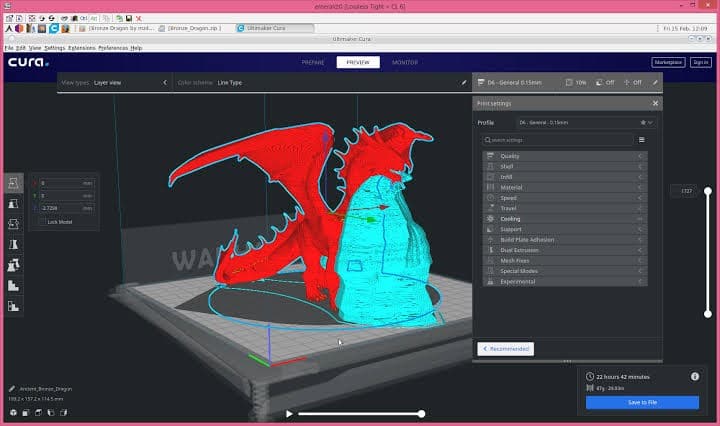

The support system that is generally used is the Tree support system since it’s unique in its approach as well as being very versatile; it has a tree-like aspect, hence the name, that supports the 3D model with its trunk and branches.

The idea behind this system is to make sure that the support branches are only attached to the overhang pieces that need to be supported.

Now, why do we recommend tree supports?

While supports may be useful in helping you achieve a better print, they need to be removed once the print is finished, which can cause damage to the print itself, or leave marks.

Tree supports are designed to only attach to the parts that strictly need to be supported, and the advantage here is that removing tree supports usually doesn’t cause as much damage as removing other kinds of supports, and this means better prints for you!

Benefits of Tree Supports

I already mentioned that tree supports tend to be superior in most situations than the other types of supports out there, but what are all the actual benefits of using them?

Cleaner surface

When using tree supports, the “trunk” of the tree does not touch the 3D print, and since the branches come out from the main structure, they are contacting only the overhanging structures that actually need support.

This means that there will be no -or very few- marks and imprints left on the print (only where the support branches where making contact), and the model itself will come out looking great.

This support system is very good for printing “letters” and figurines.

Less filament usage and minimized printing time

You do not need a lot of filament to print tree supports since you can use more infill density to make the base of the trunk stronger, but then print the hollow part with a low infill density, and this also applies to the branches themselves.

The interesting thing about creating tree supports in Cura is that it will take a while to calculate the settings with all the specifications needed for making them, but once that’s done, printing the 3D model will be quicker and use less material than if you had used another type of support.

When should tree supports be used?

You should use tree support systems when the overhang angle ranges from 45° to 60°, or higher. In essence, you are considering the relative geometry of your models here. As stated in the introductory section of this article, if your models have overhangs of 45°, you should consider using a tree support system.

If the overhang is closer to 90°, then you absolutely must use the tree support system to get good results. Also, if your model(s) is one that has complex and delicate details, you should use tree support for better detailing.

Settings of Tree Supports in Cura

Let’s start with the basics and then move on to the recommended and advanced settings you should use.

Where can you find the tree support mode?

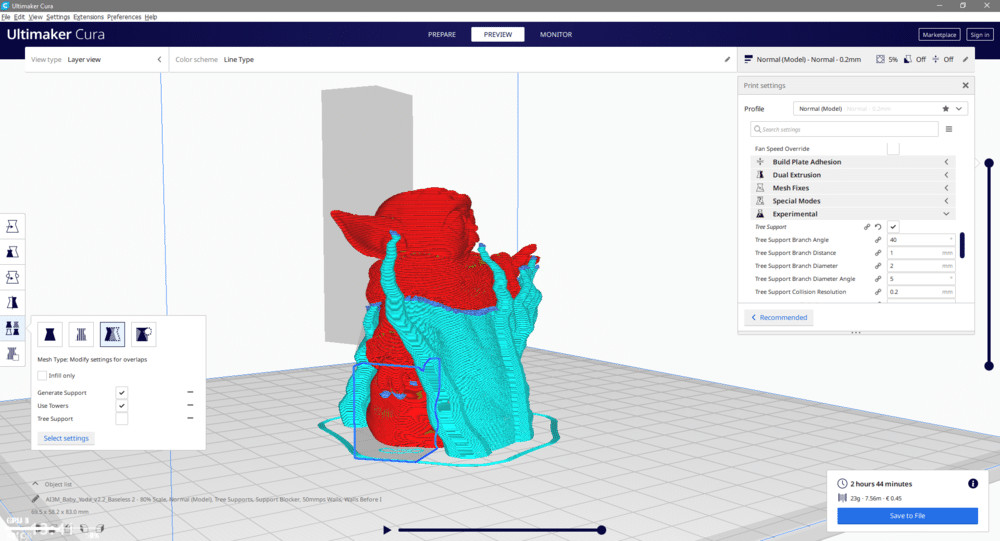

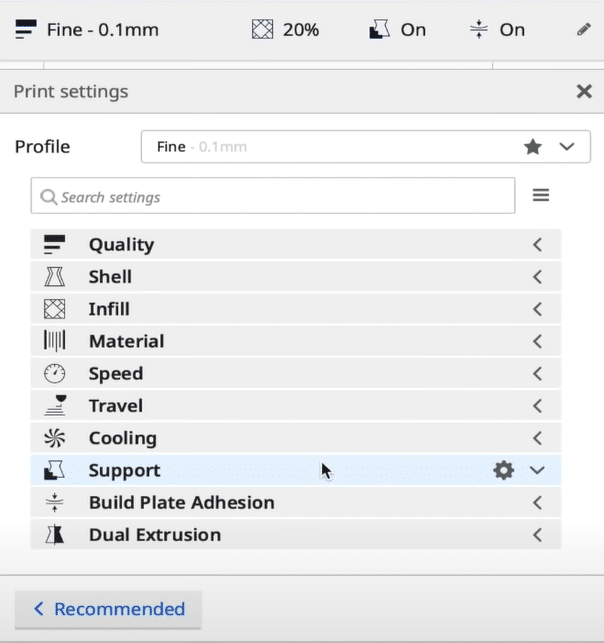

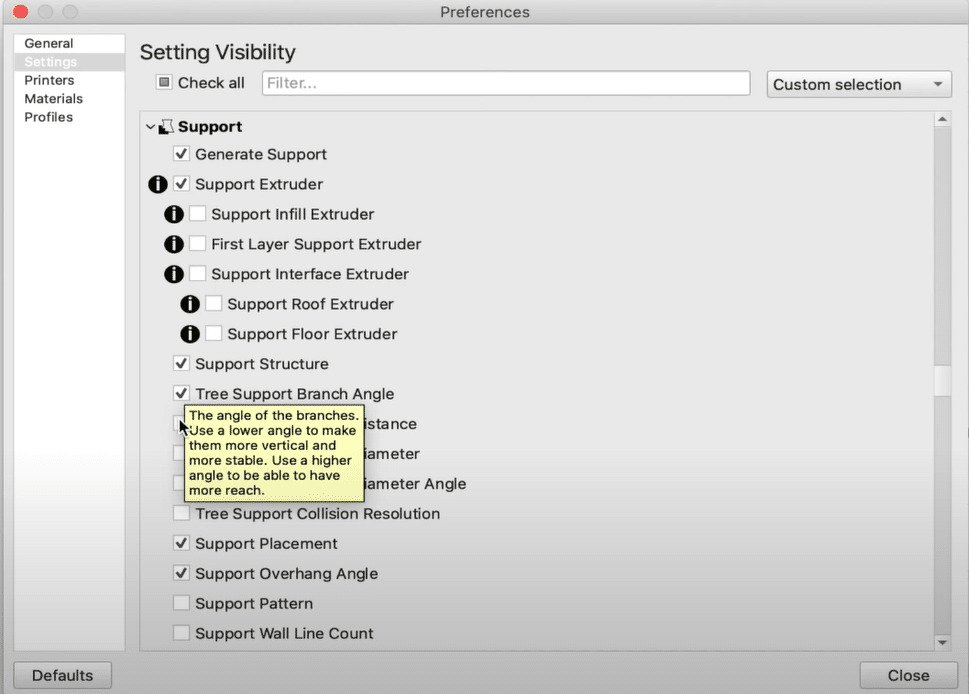

To access the tree support settings in Cura you need to go to print settings and then hover your mouse over “Supports” and then click on the “Gear” Icon.

Next activate the Cura “Support Structure” as well as all the different Tree Support options available if you want to be able to control the parameters of the supports with more detail.

Tree Support Settings

The settings that make up the tree support system are the branch angle, branch distance, branch diameter, branch diameter angle, collision resolution, wall thickness and the wall line count. In the slicer settings of a 3D printer, there is always a particular setting for all tree support systems. Here are the recommended settings.

Recommended Settings

Branch angle: This is the angle at which the branches will “grow” from the main trunk. A lower value makes them more vertical while a higher value means more strength and distance. A recommended value is 45° to 50°.

Branch diameter: A recommended setting for this is 2 to 3 mm since the trunk diameter must be of a higher value than the branch diameter.

Disable regular support settings: You must always turn off the regular support settings when you want to use tree supports. Otherwise, your 3D printer will generate both the regular- and the tree supports.

Disadvantages of tree supports

The tree support system is so effective and reliable to the extent that the downsides are almost non-existent. The only thing that comes to mind is the extra time consumed during slicing since your CPU will take a bit more than usual to slice the tree support design.

Conclusion

Tree supports will not just help you print better models, but they will also make the whole process faster and consume less material.

Even though there are a host of other 3D printing supports, the tree support system is the better alternative out of all of them, at least in most scenarios.

If you want detailed 3D prints, consider giving tree supports a shot.

Check out our recommended products section

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

Error processing API data.