When we buy a 3d printer, we think about the benefits that it can provide us: create our own parts, print collectible figures, spare parts for a broken mechanism, among others. We do not think that having a machine melting plastic in our home could affect our health in a serious way.

Today we can find 3d printers in schools, homes, and workshops, and they are not required to comply with particular security measures related to the emissions they cause. Many people, including children, may be exposed to high concentrations of small particles or toxic fumes.

Although ABS and HIPS present higher degrees of toxicity and usually contain high doses of Bisphenol A than other filaments, safety measures should be implemented regardless of the thermoplastic being used. The 3D printing process itself liberates toxic fumes as well as particles into the air, making it very important to regularly ventilate the area and not cohabitate with a working 3D printer on a regular basis.

Main concerns about the impact of 3D printing on health

Even though FDM printers have been among us for over a decade, many people claim that 3d printing might be harmful as it emits toxic particles that stick deeply in your lungs. Prolonged exposure to these particles is being evaluated by researchers in order to determine the level of danger we are exposed to when printing, both in the short- and long term.

During the first months of the COVID-19 outbreak, the sale of 3d printers grew steadily partly thanks to the implementation of this technology to manufacture face protection elements or respirators that were scarce at the time.

Many people went from having one to having multiple 3d printers in one room, which dangerously increases the emission of toxic gases as well as particles in an enclosed space. Social containment measures such as quarantines or curfews also made people spend more time inside their homes, furtherly increasing their exposure to those emissions.

According to various studies, nanoparticles called UFP (ultrafine particles), much smaller than tobacco smoke, are released during 3D printing. These particles enter through the respiratory canal and lodge in the deepest areas of the lungs where they can generate lung inflammation.

At this point, it must be clarified that not all thermoplastics used in 3d printing have the same level of toxicity. Filaments are made up of polymers with different characteristics, which break down into substances that can be more or less harmful.

I researched the level of toxicity and impact on our health of each one of the most popular thermoplastics used in 3D printing, so let’s briefly discuss them!

ABS

Abs (acrylonitrile butadiene styrene) is a hard plastic that is widely used in the plastic industry due to its low cost and excellent properties. Since it is composed of acrylonitrile, a highly toxic product, its use must be carried out under strict emission control conditions.

In addition, it emits bisphenol A, a potentially carcinogenic substance banned in some countries. Unfortunately, when it is used in desktop 3d printing, it requires an environment with little ventilation, since air currents can make it difficult to use or generate warping or cracking problems. This makes ABS one of the most dangerous materials to print with.

You should also find out if your ABS brand includes BPA (Bisphenol A), which may have serious effects on our health.

Avoid regularly printing with ABS while you are in the same room since the long-term effects could be serious.

PLA

PLA is currently the most used material in 3d printing mainly due to its ease of use. As it is derived from corn and can be biodegradable (under specific conditions) many people consider it safe.

However, the coloring agents and additives that manufacturers use could make it dangerous. It also emits high levels of UFP (ultrafine particles). It is highly recommended to renew the room’s air after every print, in order to decrease the UFP concentration.

Nylon

Nylon filaments have great durability and thermal resistance, so they are often used for printing mechanical parts. They also emit high amounts of styrene, a hydrocarbon linked to an increased risk of cancer and other diseases.

In addition, Nylon can release particles of caprolactam, an irritating compound known for causing severe damage to the respiratory system. As it needs higher levels of temperature than most 3d printing materials, it emits massive amounts of UFP.

PETG

PETG is composed of PET plastic to which glycol is added. Its chemical stability is very high, so it does not emit unpleasant odors or toxic fumes.

It is used in the manufacture of containers for drinks. However, UFP is also emitted when printing with PETG. Remember that the lack of unpleasant smell does not mean the substance isn’t toxic, as many people think.

HIPS

This material, which is often used as a support material in multi-extruder 3d printers, emits, like ABS, a compound called styrene. This compound is classified as a carcinogen by the International Agency for Cancer Research. In combination with ABS, a dual extruder printer can emit high levels of toxic fumes in a very short time. A proper ventilation system is strictly required.

As is the case which ABS, you should always find out if your HIPS spools contain BPA. We previously mentioned it and also said that it could have serious effects on our health. Because of the importance of this topic, we will dedicate an entire section to BPA.

Are 3d printing fumes toxic?

Not all filaments used in 3d printing emit toxic gases. For example, PLA can be used in environments where people work for long periods of time. Others, such as ABS, must be used in environments where the concentration of toxic fumes does not exceed the maximum allowed values.

Being exposed to these fumes causes irritation to the eyes and respiratory tract, as well as nausea and headaches. The emission of these gases can be reduced by installing a particulate filter system with activated carbon, or by increasing the ventilation in the room or workshop.

Many filament manufacturers provide their customers with a safety information sheet on the use of their filaments. It is highly recommended to check these details on the manufacturer’s website before using a new brand or material. Even different colors of the same material and manufacturer may have different levels of emissions due to the chemical composition of the pigments.

How severe is the exposure to fumes and particles in the long run?

As FDM technology is relatively new, conclusive data about its long-term effects are not yet available. Papers have been presented and their conclusion indicates that desktop 3d printers emit huge amounts of nanoparticles and their size varies between 40 and 300 nm. This size is small enough to penetrate even the innermost sectors of the respiratory system, causing severe irritation and inflammation.

Due to the toxicity of some gases emitted, there is a real risk of developing chronic lung diseases such as asthma, COPD or even cancer. Some especially susceptible individuals should work with 3d printers using additional security measures, like gas masks with appropriate filters.

Other factors that modify the values of emitted nanoparticles are the brand and type of filament, the color, the printing temperature, the use of a heated bed, etc. In general, it is recommended to set the printing temperatures as low as possible, as far as safety is concerned.

Is it safe to print indoors?

Even if filaments such as PLA or PETG are used, whose emissions are supposed to be less harmful, the environments in which 3d printers are used must be adequately ventilated, or a particle filtering system must be installed to ensure that the concentration does not exceed tolerable levels.

Another appropriate measure is to leave the room during printing time and renew the air at the end of the job.

What is BPA and how risky is it?

BPA (bisphenol A) is a synthetic compound added to many products, such as food containers, CDs and DVDs, sports equipment, or even baby bottles. It is widely used in the plastics industry, to the point that a study revealed that 90% of the US population has traces of this compound in their body.

Many reports have been published about the dangerousness of this substance and the results are often contradictory. The most severe reports indicate a direct relationship between BPA exposure and the risk of diabetes, fertility problems, cancer, and obesity. In addition, BPA could alter the neural development of children and teenagers.

In countries like France, the use of BPA is prohibited by health authorities. The international scientific community has not yet reached a consensus regarding the risks of ingesting or inhaling BPA.

Is it safe to print indoors?

Even if filaments such as PLA or PETG are used, the environments in which 3d printers are running must be adequately ventilated, or a particle filtering system must be installed to ensure that the concentration does not exceed tolerable levels. Another appropriate measure is to leave the room during printing time and renew the air at the end of the job.

Do 3d printing filaments contain BPA?

Some 3d printing filaments contain high doses of BPA, such as ABS and HIPS. During the printing time, tiny bisphenol particles are released into the air. The inhalation of these particles and their potential toxicity have not yet been sufficiently studied, so the use of additional safety measures is recommended when using these materials.

Although you should take precautions with all kinds of thermoplastics, only ABS and HIPS contain BPA in high doses.

One of the reasons that PETG is so popular among food-related utensils is that it is also BPA-free. This does not necessarily mean that you can print with this thermoplastic and apply it to your kitchen since the 3D printing process poses some issues itself that may not be food-friendly.

Is 3d printing food-safe?

Some materials used in 3d printing could be considered “food safe” due to their great chemical stability, as in the case of PETG or PLA, if the additives that are introduced during the manufacturing process are not taken into account.

Agglomerating substances or artificial colors could be toxic in certain concentrations, so each filament should be studied more deeply. In the absence of information in this regard, no material can be considered “food safe” until the relevant studies are carried out.

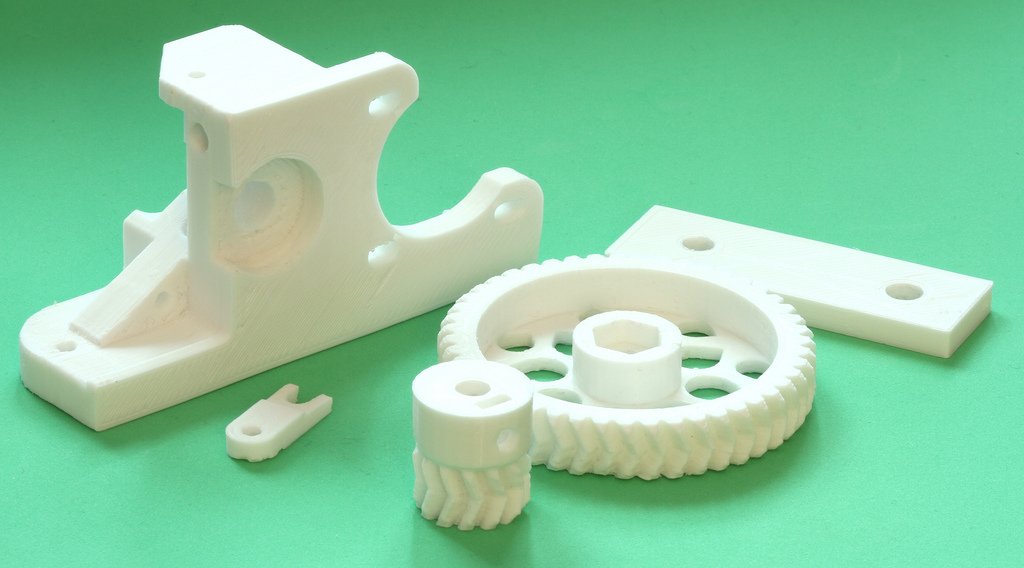

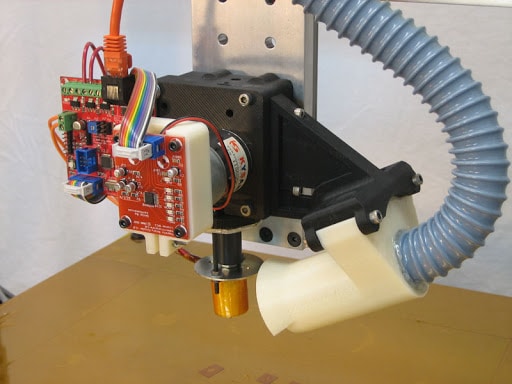

Besides that, some parts in a 3d printer’s extruder system might liberate small metal particles that end up in the printed object, altering its composition.

Another factor to consider is the stability of the polymers exposed to high temperatures. Filaments that are considered safe could release harmful substances upon thermal breakdown. Due to this, it is not recommended to consume beverages that were stored in containers made with 3d printing.

On the other hand, FDM 3d printing consists of layers of plastic of a certain thickness, which can have small holes and imperfections. Inside these cavities, food and moisture can accumulate in places where the object cannot be properly cleaned, creating an ideal environment for the growth of bacteria. If 3d printed objects are used in contact with food or drinks, they should not be reused under any circumstances.

An alternative that could solve this problem is to carry out a post-process that eliminates cracks and fills the spaces between layers in the object, with a resin approved for food use, but no studies have yet been carried out to approve the use of this technology or methods in food.

If you want to dig a little deeper into this topic, you can check out my article on the safety of filaments for printing cookie-cutter. Although it talks specifically about these utensils, the information provided here can be safely extrapolated to other uses.

You may have noticed that we only talked about FDM printers so far. In order to not exclude our SLA comunity members, lets go through the most relevant considerations that you should keep in mind when using this technology!

Is 3D printing with SLA toxic?

SLA technology is very different from FDM. Stereolithography uses a liquid resin as a consumable material, which is hardened (cured) by a laser. The process achieves a much higher dimensional accuracy than conventional 3d printers, which is why it is used to make more detailed parts, or objects with a very small size that could not be made by FMD.

The drawback in the use of this technology is the high toxicity of the resin when it is in a liquid state and when curing during printing. When it comes into contact with the skin, it sometimes produces an instant irritation reaction. Some people don’t notice this reaction for several days. If the contact is prolonged for a long time, the skin can develop allergies or even increase the sensitivity of the body to the resin or UV lights.

Cases have been reported of people who worked with resin without using protection for some years. Now they can’t be in contact with it as even the smell of the resin gives them a headache.

As 3d printing resins are much more toxic than filaments for FDM printers, their use must be carried out in controlled environments where additional security measures are established. Latex gloves and eye protection must always be worn when handling liquid resin.

Is SLA food safe?

Once cured, the resin becomes hard and relatively stable. However, with daily use, a piece printed with resin interacts with chemical compounds present in food and can release toxic substances. For this reason, an optimal level of safety in the use of this material on objects that come into contact with food cannot be guaranteed.

There are resins for use in biomedicine, which are classified as “biocompatible”, but this certification is given for very specific uses in medicine and dentistry. Their use is not recommended in applications other than the original one for which they were developed.

One way to use SLA 3d printing in the food industry is to make negative molds for vacuum forming. With these molds you can thermoform approved plastics for use with food. In this way, the food does not come into contact with the resin mold but with the safe plastic one.

3d printing is still under analysis, and long-term conclusions about its health impact are yet to be made. As long as we don’t have enough information, it’s better to stay safe and prevent damage by increasing security measures.

Check out our recommended products section

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

Error processing API data.

What precautions should be taken with an ender 3 v2 to be safe?