By now, everyone has heard of 3d printing and how it is disrupting multiple industries and creating new opportunities every day. The most popular technologies used by the maker community are fused deposition modeling (FDM) and Stereolithography (SLA) printers. Nonetheless, more demanding requirements oftentimes ask for more expensive and industrial-grade machines, such as PolyJet printers.

We might wonder what they are, how they are used and how epensive they are!

PolyJet printers work by jetting droplets of photopolymers layer upon layer. Each layer gets instantly cured under UV light and, by doing so, the object is systematically built up. PolyJet printers allow for multi-material printing, enabling models to have more than one technical profile. Due to the inherent advantages of PolyJet printing, it is used in the aerospace, automotive, fashion, railway, and medical industries.

What is a PolyJet 3d printer?

Names in the 3D printing world can be confusing, and oftentimes there will be two or more names for the exact same technology or product. A good example is FDM (Fused Deposition Modeling) and FFF (Fused Filament Fabrication), which refer to printing with thermoplastic filament.

PolyJet or Poly Jet is no different when it comes to names because it functions on the same principles as the Material Jetting (MJ) printers. The company Stratasys developed their own liquid jetting technology and called it Poly Jet because it links to the technology.

This printing method uses photopolymers as a building material, and the technology jets photopolymer droplets onto the build platform, which are cured by UV light. The process is extremely fast, and accuracy levels are of the best in the 3D industry.

The company 3D Systems named their printers using this technology, MJ printers or MultiJet printers. Here again, the name is directly linked to an aspect of the technology as it uses multi jets to spray or accurately deposit the liquid photopolymer material on the build plate.

As you can see, the names used in 3D printing may initially sound confusing but are, in actual fact, quite logical. The reason for the industry not conforming to a common name for a specific technology type has a lot to do with branding association and marketing. The more attention a company can muster around their products, the better their bottom line will be. It’s very similar to a game of Survivor where Outwit, Outsmart, and Outplay have a fourth dimension, “Outname”.

Photopolymer Jetting 3D printing falls under or is a subclass of the material extruding/jetting category. Material jetting uses technologies that jet liquid photopolymer material from a print head subjected to and cured by UV light. Not all but most material jetting processes make use of photopolymers as the build material.

Stratasys is considered a world leader in FDM (FFF) printing technology, and their acquisition of Objet in 2012 also led to PolyJet and PolyJet Matrix printers. PolyJet printers are capable of multi-material and multi-color printing, which deliver high-quality prints.

How does a PolyJet printer work?

In many ways, PolyJet 3D printing is similar to inkjet document printers. The difference is that Polyjet printers print 3D models, giving them that extra dimension. This is achieved by printing layer upon layer, much the same as FDM printing.

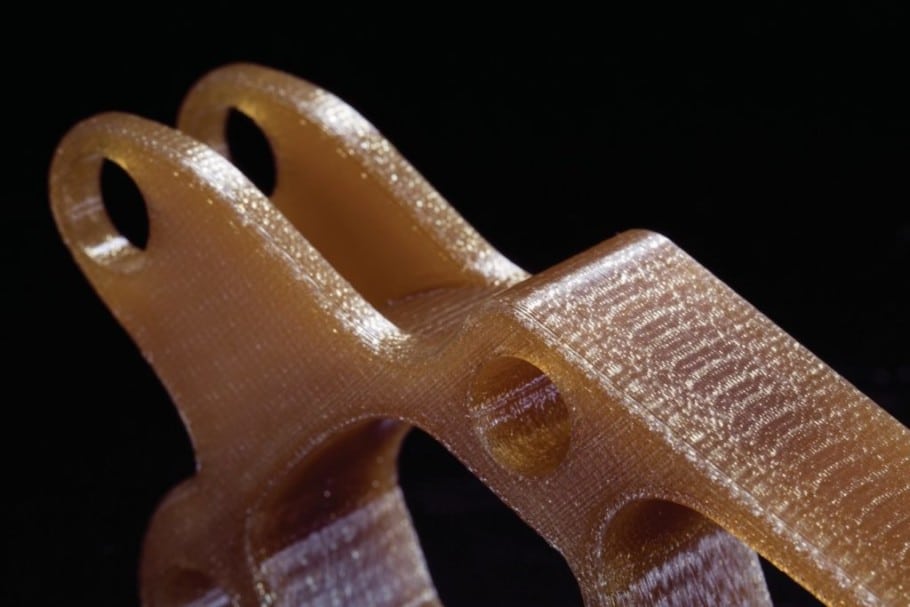

Each layer deposited is cured under UV light, and in this way, the print is systematically built up. On completing a print, it can immediately be handled and utilized without the need for further post-curing, which is a great time saver.

Print supports are still required for overhangs and other geometrical design elements that require support until the curing process is complete. A specially designed gel-like material is used where support is needed, and once the print is complete, the supports are easily removed by hand, washed with water and finally emersed in a chemical to remove the remaining support material.

There are numerous advantages to PolyJet printing that include print speed, outstanding precision, and quality, as well as a large variety of print materials that can be used simultaneously, as is the case with Stratasys’s Objet Connex 3D printer.

PolyJet printers work on the same principles as material jetting 3D printers. Before printing commences, the photopolymer material in the printer’s material reservoir must be heated to the optimum temperature to ensure the correct printing viscosity.

Printing begins with the carriage moving across the X-axis of the build platform. During the movements, the print head will selectively jet the resin in very fine droplets onto the build platform, and they will be immediately cured or hardened with UV light.

With the technology of multiple print heads, supports are printed at the same time using specific support material that is easily removed afterward. After each layer is complete, the build platform will move down a notch, and the process is repeated until the print has been completed. Bio-resins are among the wide range of material choices.

With PolyJet technology, finished prints are sprayed with pressurized water to remove support material and dunked into a chemical solution to dissolve the last bits of support material. MultiJet printers use paraffin wax for their support material which needs to be melted away in an oven.

It is always intuitive and nice to see a printer in action in order to fully understand how it works, so take a look at the following video!

Is PolyJet similar to FDM?

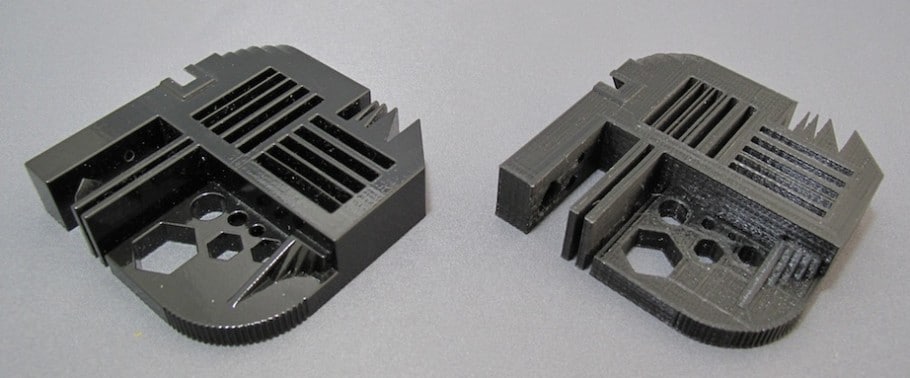

Although PolyJet and FDM printers both build a print layer by layer, the process used in each differs greatly. FMD printers use thermoplastics as a material, while PolyJet uses liquid photopolymers.

In FDM printing, the thermoplastic filament is wound on a spool and fed into the print head, where it is melted and extruded as a layer and will cool and solidify. Each layer goes through the same process until the print is complete. In PolyJet printing, each layer of jetted liquid resin is cured by UV light, and the layers build up to form a completed print.

Is PolyJet similar to SLA?

PolyJet is similar to SLA printing in that they both use a liquid resin that is cured by UV light, but the processes are very different. SLA prints the design upside down using a resin vat or bath to print the model from, while PolyJet printers spray tiny droplets onto a build plate and built it up that way.

Both printing methods print layer by layer, but PolyJet printing has distinct advantages over SLA printing. For starters, it is not restricted to only resin type, and the support material is washed off with no need for a time-consuming post-production process. On a print volume scale, PolyJet is capable of higher print volumes due to the dried cured finish.

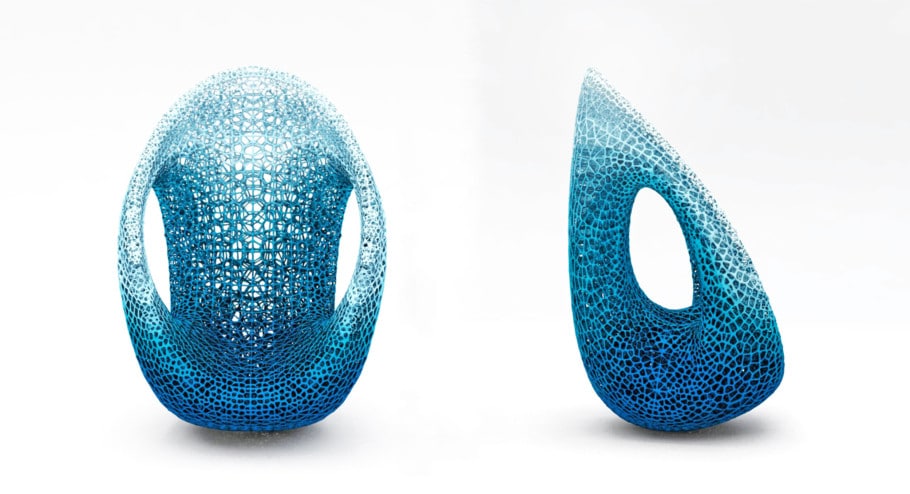

The biggest advantage that PolyJet has over SLA is the multi-material usage that has the ability to alter the structure of the final product. Where SLA produces a uniformed print that is set in its rigidity, PolyJet combines different materials in the print to allow for a certain area to be rigid while other areas can be more flexible.

What materials do PolyJet printers use?

The range of photopolymer materials used with PolyJet printers is wide-reaching with many different applications. Listed below are a few applications that have added value to the medical and dental industry.

- BoneMatrix: Models that mimic porous bone structures, fibrotic tissues, and ligaments.

- GelMatrix: Detailed vascular structures.

- Med610: Surgical guides for dental implants or other orthopedic procedures.

- Med620: Accurate try-in models for dental work

- Med690: design durable crowns and bridges.

- VeroFlex: design eyewear frames.

It is interesting to see how the different materials mimic the true-life function of the part created. In dentistry, it is possible to create a softer denture frame that is like soft rubber, limiting the direct pressure on the actual gum tissue below. The ability to create strong, durable prosthetics that take on the feel of actual tissue and bone structures is phenomenal.

Advantages and disadvantages of PolyJet 3D printing

As is the case with everything in life, there are advantages and disadvantages. Since 3d printing is a subset of life, it should therefore also have its pros and cons. Leaving the nerdy wording aside, lets go through tem!

Advantages

- PolyJet prints are accurate up to 16 microns and have a smooth surface finish that compares very well to injection molding. The print process allows for the printing of multiple parts at the same time without any loss of speed.

- Designs can be created and printed in full color, and different materials can be used on the same print as well. This is made possible thanks to the use of multiple jetting print heads.

- The curing process with PolyJet technology is instant, and prints can be used right away.

- PolyJet technology allows for superior print detail, and print supports are easily washed off once the print is complete.

- There are currently more than one hundred print materials to select from, and the number is growing continuously.

Disadvantages

Despite the many advantages, the mechanical properties tend to fail Polyjet printing to a degree as they are oftentimes worst than FDM and SLA printed parts. PolyJet prints are susceptible to heat and sunlight and will lose their strength over time. Of course, this depends on the materials used and, since there is an enormous repertoire of options, most use cases can be properly addressed by correctly choosing the material

The other negative is that Material Jetting printers and materials can be very expensive and out of reach for many 3D enthusiasts.

Is PolyJet expensive?

The simple answer is yes, PolyJet is expensive. This could be due to the fact that material jetting is a relatively new addition to 3D printing and is predominantly used in professional settings. This should not put a damper on exploring the options that material jetting has to offer compared to FDM or SLA options.

If you want to acquire a PolyJet printer, you should expect to invest at least $35.000. Given that number, you should really know what you are going to use it for, since printing high quality PolyPikachu’s won’t make much financial sense.

Recommended alternatives for printing at home

Unless you’re willing to fork out $35.000, then you probably need to look elsewhere to get your hands on a 3D printer.

There are multiple printers currently on the market that won’t break the bank and that can produce really nice-looking models.

I own an Ender 3 Pro and it’s a fantastic little printer considering it cost me less than $200, but you can also invest in a Prusa MK3S+ which is a much better printer, but it also costs just a little more (a “little”).

Lastly, if you’re more of a Resin printer fan, consider the Elegoo printers, such as the Elegoo Mars 3 Ultra 4k, which is an amazing printer for creating your own high-detail miniatures.

Applications of PolyJet 3D printing

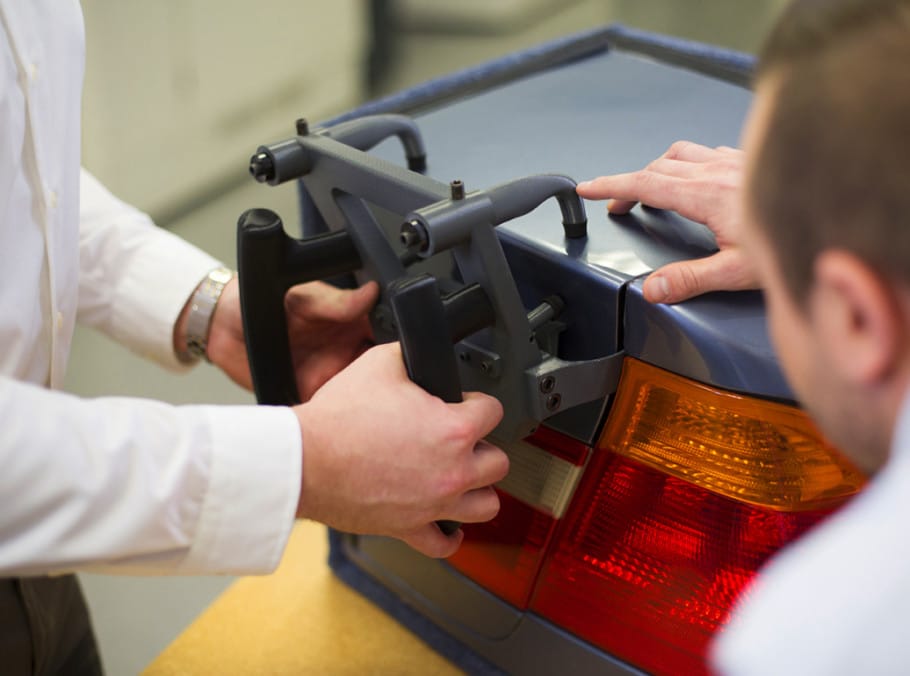

As stated, the application of PolyJet printing technology is wide-reaching and is sought after in professional settings as it copes well with intricate detail and delicate features regardless of the design complexity.

In the US, Polyjet printing can be found in the automobile, architecture, industrial and educational sectors. The medical industry shows strong support for PolyJet printing of prosthetics and joint replacements as well as in dentistry. Dental applications are common in developed countries but not as much in emerging economies like India, so there is great potential for both US and worldwide growth.

PolyJet in the Healthcare industry

Dentistry has embraced material jetting technologies because it has allowed for the clear aligner market to be upscaled. The ease of printer operation and the speed of printing means that on-demand requests can be met.

Aerospace

Enormous savings have been made possible with the use of PolyJet technology, and one such example is the saving of $3.8 million by the U.S. Department of Defense with a further expected saving of over #15 million in the next 10 to 15 years.

With new aircraft designs constantly on the table, prototype parts are essential, and there is no easier way to create them to specification than with using material jetting technology.

Automotive

The automotive industry has benefited greatly from 3D technologies, and the inclusion of material jetting as an option for rapid prototyping, tooling, jigs and fixtures, and production parts has greatly benefited the industry.

Railways

With PolyJet technology, the production time for customized production-grade parts has been reduced by up to 95%, which in any industry means efficiency and effective response in presenting solutions that are safety compliant.

Art & Fashion

Art and fashion have become a collaboration with 3D printing technologies where companies like Stratasys bridge innovation with a creation that encompasses not only technological advancements but also reflects philosophical and cultural dimensions. One such development is jet printing with chocolate which is just one of many applications for PolyJet technologies.

Conclusion

By now, you should not only have a good understanding of PolyJet printing but also have an aggressive desire to own one. While you save at least $35.000, I personally recommend getting a hobby-grade FDM or SLA printer to get your toes wet in the overwhelmingly huge 3d printing world. Not only will you find out if you are interested in this industry, but also might learn that you don’t need a state-of-the-art industrial-grade machine to fit your needs.

Check out our recommended products section

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

Error processing API data.