The most probable cause that brought you to this article is having a 3d printer that is currently unable to properly feed filament. So let’s make this intro short and go straight to answering the following question: how do you fix a 3d printer that is currently not feeding filament?

The main causes that lead to a 3d printer not feeding filament are a clog along the extrusion path, a damaged PTFE tube, incorrect retraction settings, unwanted filament tension, too high (or too low) extrusion temperature, a clogged nozzle or worn-out driver gear.

I know, this list of issues is not very helpful if we do not address each cause individually, and that is exactly what I’ll do in this article! As is the case with most troubleshooting articles, the readings are of a reactive instead of preventive nature. That’s obviously the way it should be, but I’ll also give tips and tricks to avoid these issues in the future. It’s not that I don’t want you to come back to our blog, but I really think that we have lots of more interesting and happier articles for you to read!

Common causes of 3d printer not feeding filament

Extrusion path clogged

To properly feed the filament, your 3D printer needs to have a clear extrusion path. Any obstructions here will mess with the flow rate of the filament. To fix this problem make sure your filament has a smooth and clear path, this means checking all the way from the filament spool to the extruder nozzle. Ideally, the filament spool should be close to the extruder nozzle and the filament should be coming at a curved angle.

PTFE tube may be damaged

If your heatsink is not working properly it could lead to heat traveling outside the melting zone. This heat can damage the PTFE tube jamming the filament. Check the PTFE tube ends for any signs of deformation. If necessary, replace the PTFE tube with a higher quality one for better insulation and higher temperatures.

The tube I just linked is the blue Capricorn tube that comes with a tube cutter as well as a couple nozzles, and this tube is much better than the standard white/transparent PTFE tube that comes with most printers, such as the Ender 3.

Incorrect retraction settings

The retraction settings let you control the length and speed at which the filament will retract into the extruder nozzle when changing the extruding location. This is done to avoid leakings while the nozzle moves to a different spot.

If you are retracting too much filament or the retraction speed is too high, the back and forth movement could grind the filament making it harder for the drive gears to keep moving it. Start with a 40mm/s speed and 5mm retraction length, if you see signs of stress in the filament lower those settings.

Filament tension

If the filament tension between the drive gears and the spool is too high, the drive gears will need to work harder to move the filament resulting in the gears eating the filament to a point where it messes with the normal feed flow.

Extruder temperature

If the extruding temperature is too low the filament will have a harder time going through the nozzle. Try increasing the temperature by 5-10 degrees as it will allow for easier filament flow. Always check your filament spool for the recommended melting temperatures. Too high temperatures can also be a problem, melting the filament before time thus jamming the system.

Worn-out drive gear

In some cases after a lot of work, the teeth of the drive gear can get worn out and stop properly feeding the filament. Check them to see if you need to replace them and if necessary get a new extruder hot end. For years of good 3D printing get a high-quality hot end.

Clogged nozzle

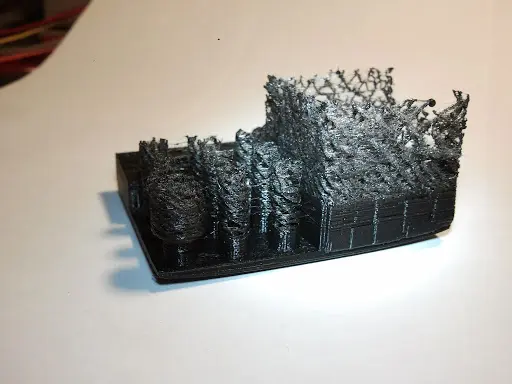

If you notice that filament is not going through the nozzle or that it is coming out stringy, it might be due to a partially or fully clogged nozzle. Over the lifetime of a 3D printer, you will need to make sure to maintain a clean nozzle to ensure quality 3D prints. As your 3D printer melts the filament and pushes it through the tiny nozzle, some leftovers might get stuck there and eventually jam the system.

Since this is a common issue and most probably the cause of your printer not feeding filament, we will go into further details and explain some tricks to avoid this problem in the future. Additionally, I’ll also explain step by step how to solve it.

Causes that lead to a clogged nozzle

Bad printing temperatures

If your printing temperature is too low, the filament will not melt properly thus making it harder for the drive gears to keep the filament going. At some point, the pressure will be so high in the extruder that the drive gears will start stripping the filament and the filament left in the nozzle will solidify and become a plug.

On the other hand, if your printing temperature is too high, the heat can spread out of the melting zone and start melting the filament before it should have. This effect is called “Heat Creep” and when this happens, the drive gears will have a hard time pushing the softened filament. Eventually, the drive gears can not keep up and the nozzle gets clogged. To prevent this always check the recommended temperatures for the material you are using.

Dust and dirt in the filament

If there are dust or dirt particles in your filament, they will burn as the filament goes through the melting zone. These burnt particles can stick to the inside of the nozzle, alter the proper filament flow, and eventually fully clog the nozzle. This issue is difficult to address, you should try your best to keep the filament clean. Store it in a plastic bag after the package was opened.

Nozzle too close to the print bed

When the nozzle is too close to the print bed, the filament will not be properly extruded as there isn’t enough space. This will cause the filament to be smeared all over the print bed as the nozzle travels. The lack of space between the nozzle and the print bed will produce retrograde extrusion. This means the filament will go back into the nozzle and the extra pressure this generates will likely cause a clog in the nozzle.

As a rule of thumb, the height should never be bigger than the nozzle diameter. A good starting point is to use a quarter of the nozzle diameter as the height. If you are using a 0.4mm nozzle, you can calibrate your printer by using a sheet of paper. The distance between the print bed and the nozzle should be enough for the paper to be placed between them, although relatively tight. This is the most common “calibrating tool” used since it normally has a 1/10 millimeter thickness.

Low-quality filament

Low-quality filaments can be problematic as these filaments don’t get a rigorous test before they go to the market. They can present different diameters at different points, the thinner parts can be difficult for the drive gear to grab, and the thicker parts will take longer to melt.

These variations in the melting point create an uneven and unclean flow of the filament which can lead to clogs. You can use a caliper and check different spots on the filament for diameter changes if those values show big differences you should change your filament.

I wrote loads of posts regarding the different filaments out there and what each one of them is generally used for, and much more.

However, here’s a quick list of the filaments/brands I’d recommend:

How to unclog a nozzle

There are a few different methods that you can use to unclog the nozzle. These vary depending on how clogged the nozzle is. Try the following methods.

Unblock a partially clogged nozzle

- Brass wire brushing: The first method you should try is to use a brass wire brush to clean the outside of the nozzle.

- Cleaning filament: Cleaning filaments are specifically made to clean the nozzle. Print with them using the recommended settings on the package. As it goes through the nozzle it should carry with it all the leftovers that were clogging the nozzle. You should be doing this every time you change filaments as it will help to prevent any clogs.

- Manually push the filament: Heat the nozzle to the proper temperature for your filament, then manually push the filament through the nozzle until some of it is extruded. In some cases, the extra force provided is enough to eliminate the obstruction.

Unblock a fully clogged nozzle

- Guitar string/Needle: You can use an acupuncture needle or a high E or B metal guitar string to clean the nozzle. The needle/string needs to have a smaller diameter than the nozzle to avoid damaging it. Heat the nozzle to the correct temperature for the filament you were using and then gently push the needle/string through the nozzle to break the blockage. The next time you extrude filament it should come out with the particles that were clogging the nozzle.

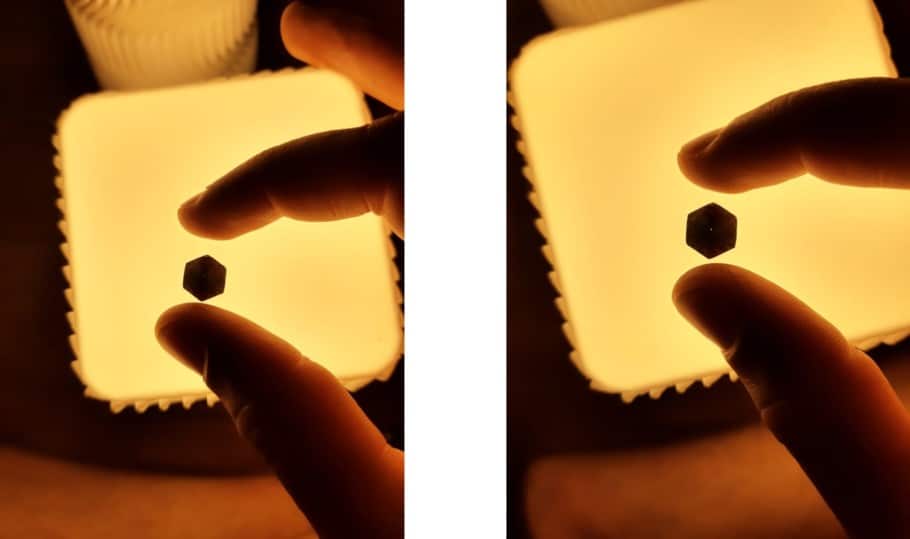

- Atomic/Cold pull: For this method, we recommend using Nylon or ABS as PLA is more fragile. Heat the nozzle up to 250 degrees celsius for at least 5 minutes and then push your chosen filament through the nozzle until it starts oozing out a little. Let it cool down to room temperature so the filament solidifies and then heat it to 120 degrees celsius. Pull out the filament with a steady and firm jerk, you should see the dirt particles in the filament. Repeat the process until the filament comes out clean and the tip of the filament preserves the shape of the nozzle.

Source

- Acetone: You can try using acetone to free the nozzle from obstructions. Remove the nozzle from the printer and place it in a recipient, then pour acetone until the nozzle is fully submerged. Leave it there for 24 hours, shake the recipient every few hours to help dissolve the obstructions. You can even use a needle while this is going on to see if it helps to break the blockage. After 24 hours, take it out and make sure to dry it with a towel so there aren’t any acetone leftovers.

- Heat gun: Last but not least you can try to melt the obstructions with a heat gun or a blowtorch. Remove the nozzle from the printer and hold it with pliers against the heat gun. Avoid direct heat if you are using a blowtorch as it can melt the nozzle. Check against a light source to see if the nozzle is clear of obstructions. Use a needle if it is still clogged.

Conclusion

By now, I hope you were able to solve your issue. I think I’ve gone through most of the issues you can come across that lead to having this annoying issue. If your problem still persists, there’s no shame in reaching out to a local 3d printer expert that services 3d printers for a living. He will surely be able to fix your printer and let you know what caused the issue in the first place. If you are like me, you will surely ask him a ton of questions in order to know how he solved the problem!

Check out our recommended products section

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

Error processing API data.