More often than not, we can be relatively confident that our 3D printer is well calibrated and ready to print incredibly good looking objects at our high quality standards. Suddenly, we decide to print a new object with a spool of filament that has not been used in a while. To our surprise, we notice that the outcome is well below our usual expectations.

So, can a spool of filament go bad and lose its properties? What are the most probable causes of this problem?

If the filament is not stored in a sealed container with silica gel it will absorb moisture which makes it brittle, as does exposure to UV light since it can also turn the filament brittle and prone to breaking, and the spool can also get tangled if not properly secured to the holes of the spool before storing it.

In summary, here is a table of causes that can render a spool unusable, its consequences and its solutions.

| Cause | Worst Filament | Best Filament | Consequences | Solution |

| Exposure to UV light | – PLA – ABS | – PETG – ASA | Filament gets brittle and prone to breaking | No solution |

| Exposure to moisture | – PLA – ABS – PETG | – HIPS – ASA | – Poor adhesion to build plate – Bubbles in nozzle – Heterogeneous results – Start and finish of extrusion get delayed – Nozzle stops extruding | – Dry in oven at 40°C for 3 hours – Use a blower dryer – User an Air Purifier |

| Tanglement in spool | – Affects all | – Affects all | – Nozzle stops extruding filament | – Always secure the tip of filament in the spool holes after usage. |

| Spool holder friction | – Affects all | – Affects all | – Nozzle stops extruding filament | – Place spool on objects that are less prone to generate friction. |

How long does filament generally last?

If the filament is stored in a dry and relatively cool place and kept in its packaging to prevent moisture, you can expect your filament to keep its properties for at least 2 years. This holds true for most popular thermoplastics, like PLA, ABS, and PETG. The exception to this rule is Nylon, which generally stops working as well after 12 months of shelf life.

Keep in mind that the filament’s printing quality can be kept for much longer than 2 years, but you will need to use it in order to find out, but generally avoid purchasing filament spools that have been sitting on a shelf for two or more years.

Regardless, there are too many variables involved, so it’s almost impossible to know definitively how long any given spool of filament will last you.

The lifespan of filament depends on a lot of factors, like the filament’s local atmospheric conditions, its exposure to sunlight, temperature, and humidity), and the initial quality and type of the thermoplastic.

PLA

Typically, PLA Filament has a shelf life of about 2-3 years. This means you can buy it, store it in a cool, dry, and dark place in its original packaging (to prevent moisture), and still be able to print with it almost 3 years later. Keep in mind that after 2 years the print quality may start to degrade.

PLA filament can last a long time before it begins to get brittle and show signs of wear, but certainly avoid PLA spools that have been stored in a hot garage or out in the sun since PLA doesn’t like heat or being exposed to UV light.

On the other hand, PLA stored indoors at room temperature can last for a couple years without a decline in quality.

ABS

ABS filament has a similar shelf life to that of PLA, meaning that, if not exposed to moisture, it can last up to two years once its been taken out of its packaging.

ABS is a stronger and more durable material than PLA. Because it has a higher glass transition temperature (105°C compared to the 60°C of PLA), it can better withstand the heat.

Although it is less prone to water absorption than other thermoplastics, it is still a good idea to be on the safe side and keep your ABS spools in friendly environment. By this I mean to keep it inside its packaging with multiple silica gel bags, not in direct sunlight, etc.

Nylon

Nylon’s great affinity for water is problematic, it absorbs water like a sponge, which causes it to swell and bind up the printer nozzle which can create inconsistent outputs.

In only a few days, it can absorb between 1% and 3% moisture, and this high water content will cause the material to fail when printed.

In technical terms, Nylon is a thermoplastic that has the property of being hygroscopic. It is a fancy way of saying that it loves to absorb moisture.

For this reason, if Nylon is left in the open, its lifespan will be reduced significantly in a matter of of days. It is also unsuitable for printing products that are meant for outdoor uses. Most Nylon brands have a maximum shelf life of 12 months.

It is worth noting, however, that all filaments are more or less hygroscopic and will absorb moisture. However, they can only absorb a certain percentage of it and that’s it. This obviously isn’t ideal for printing with the filament since moisture can create all kinds of problems, but if you don’t mind your print swelling up slightly, then you can certainly leave printed models outside and once they have absorbed some moisture, they won’t absorb any more.

PETG

PETG is a co-polyester, it has two main components: PET and glycol. It is stronger and more durable than PLA as well as a little bit more flexible; PETG filament has a higher glass transition temperature which means it doesn’t deform as easily as PLA when subjected to low forms of heat (in a car, for example).

Store PETG filament in an airtight container to keep it away from moisture. Storage temperature is also critical. PETG filament can last a long time if it is stored in a cool place, but if the filament is exposed to heat, it will become brittle and crack, especially when simultaneously exposed to moisture.

Most PETG filaments can be stored for 2 years or more before it becomes brittle and cracks. You should keep it in a cool place and away from moisture or direct sunlight to make sure it retains its qualities as long as possible.

Now, where PETG differs from the previous filaments as well is that it’s UV resistant, making it a great filament overall for outdoor use.

How to tell if a filament has gone bad and what causes it?

The bad news is that there’s no clear way to tell if a filament spool has gone bad. The good news is that 3D printers will not be damaged in any way by using old filament, so you can always try and print a test quick test object to check the overall quality of a spool.

People recommend the following three tests to identify a bad filament:

- Stretch test: It’s not a fully reliable method since PLA can be a bit more flexible before breaking down. This method also requires that you have a bit of faith in your own powers of observation. I consider this to be a waste of time since it does not yield conclusive evidence.

- Stress test: An even less reliable way to examine PLA filament for signs of degradation is to leave it hanging vertically for some time before testing. Also do not recommend it.

- Print a small object: this is by far the best way to test the current quality of a spool of filament. Print a small object with your usual settings and check if the output is as good as you would expect. If you hear popping noises during the extrusion, you can be certain that you are dealing with moist filament.

As you may have noticed, I’m clearly not a huge fan of the first two recommendations that are usually tossed around. Why would you perform tests that give you a hint of the quality if you have a quick and easy way to test the very thing you are trying to measure!

How does moisture affect filament?

Moisture accumulated in a spool can lead to very low-quality prints and even breakage. If your filament is coming off your spool stretched out and stringing, it could be an indication that your filament is not sufficiently dry.

The consequences of printing with wet filaments are numerous, and it is one of the main causes when obtaining bad results.

Just read through the list of possible consequences of wet filaments. You certainly would like to avoid this!

Wet filament may lead to:

- Finding holes on the top layers of your parts

- Bubbles on the tip of the extruder

- Poor adhesion to the build plate

- Very heterogeneous outcomes when printing the same model

- Start and finish of extrusion is delayed, leading to poor quality

- Nozzle randomly stops extruding filament

Why does moisture have such a big effect on printing quality? What exactly happens?

Foaming

The foaming phenomenon is the main reason for filament expansion. It is bad for your prints. It makes the layers weaker and can make the print look like a slice of Swiss cheese. It is caused by two factors: evaporation of absorbed moisture, and excessive retraction.

Foaming is the process by which the polymer molecule is broken down into a gaseous state. Polymer molecules are large and can unravel easily. As a result, they lose strength when wet and can even break into separate sections. The energy required to disrupt these bonds makes the filament swell up and expand.

Hydrolysis

Hydrolysis is another process that happens at an atomic level: As the polymer soaks up water, it degrades by breaking some of its chemical bonds. This turns the polymer into a monomer.

When you’re using your 3D printer, a filament with low moisture content is very important. Bubbles in the print turn even the most beautiful design into a jumbled mess. Proper filament drying ensures that your designs come out clean and beautiful.

How to fix filament that has absorbed humidity?

Probably the simplest, most cost-effective way to gradually equalize humidity across a filament is to desiccate it using some kind of oven.

A regular kitchen oven is the fastest way of drying filament spools. Heat can evaporate a lot of water from the it which will help you get rid of excess moisture and make your 3D printing experience trouble-free again.

Kitchen ovens will do a good job but before using them, however, you must consider that they are not designed to heat filaments, so you must be extremely careful not to melt them and definitely set the temperature way below the glass transition temperature of the filament.

In order to properly dry a wet spool of filament, set the oven to 40°C (104°F) and leave it there for about 3 hours. Every now and then check how the process is coming along, especially to make sure that the temperature isn’t too hot and melting the filament.

Remember that the glass transition temperature, the temperature at which PLA starts to become malleable, is only 60°C (140°F). If your oven reaches or exceeds that temperature just for a few minutes, you can be certain that the spool is ruined for good.

Although I tend to use the oven as my go-to solution for drying wet filaments, I should also mention other techniques used by the printing community:

Food dehydrators also work well since they are essentially designed to suck all moisture out of food, and they will also do this to the filament.

Lastly, there are a couple products out there specifically designed for drying filament called, you guessed it, filament dryers and they are a fantastic way of keeping your filament moisture free, plus you don’t run the risk of melting the filament like you would when using an oven.

How to properly store filament?

In order to stop moisture from being absorbed by your filament, most suppliers ship their filaments with a tiny bag of silica gel. Silica gel is a desiccant, i.e. a product that absorbs moisture from its environment.

You should store all filaments in an airtight container or ziploc bag with those silica packets, or you can simply fill up a small storage container will silica beads, rice, etc. and simply put the filaments inside of it.

Common ways of ruining your Filament (and how to fix it)?

So far, we’ve been mostly preocupied with humidity, wich is the most probable way of ruining an unused spool. Needles to say, there are many other ways by which we can ruin our filaments, so let’s go through each one of them.

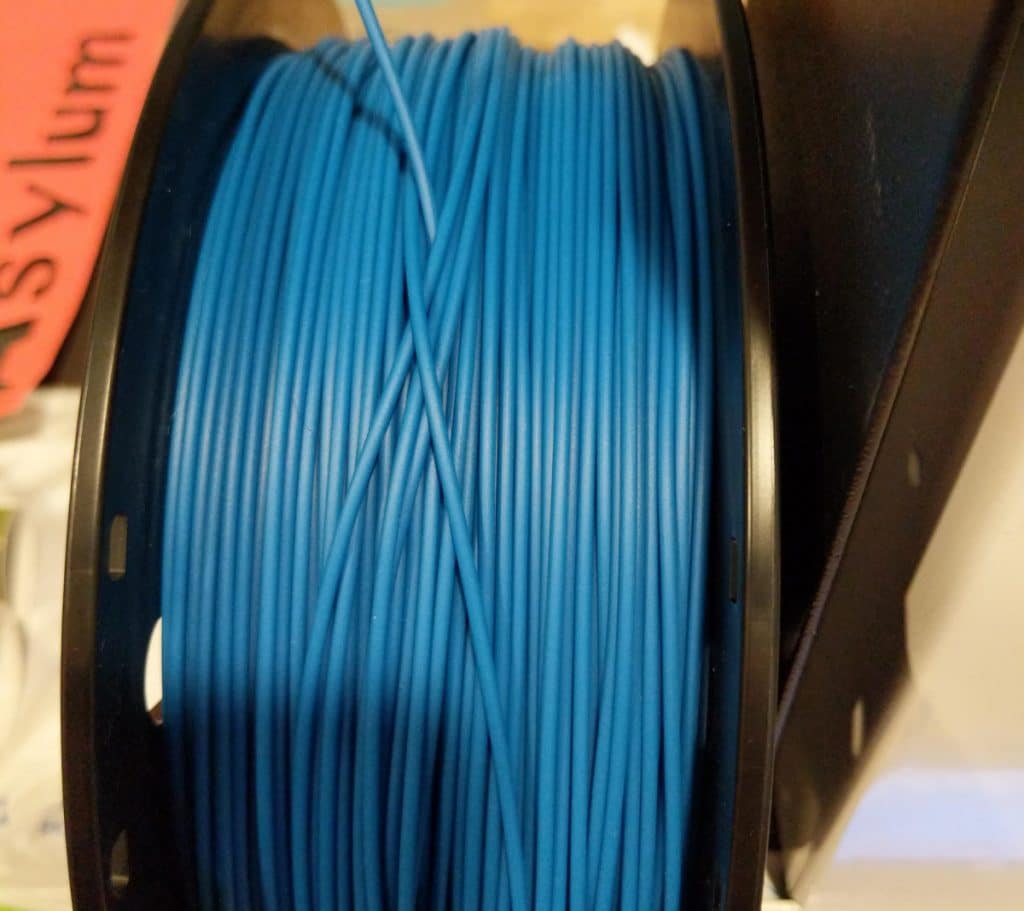

Tangled filament spool

Seriously, it’s the most common issue I encounter as someone who makes a decent portion of their income 3d printing. The operation of FDM printers is simple. Every printer gets the plastic filament from a reel, which in turn is connected to a spool holder. The printer pulls out the filament from the reel and melts it into a thin string with a hot nozzle.

The plastic filament is actually winded on a plastic or metal spool in the form of circular coils. 1 KG spool can have up to a hundred coils. One end of the filament is tied to the spool and the other end is fed to the printer.

Whenever your going to store the filament, make sure to insert the loose end into the holes available on the side of the spool to keep it from tangling.

If your printer receives its filament from a tangled spool, it will most probably be unable to keep pushing the plastic through the nozzle, it will jam halfway through the print the entire progress will be lost. This is quite an irritating, time-consuming, and costly mistake.

However, tangles are quite easy to avoid. All you have to do is never let the loose end of the filament be free. If it is not in the printer, it should either be in your hand or secured tightly to the holes present in the rims of the spool.

If, however, you find that your filament has tangled up, simply start unwinding it from the spool manually and then re-wind the filament yourself and stick the end into one of the holes so it stays nice and tight.

Keep your filaments away from children, animals, or irresponsible adults!

Having a pet, toddlers, or an irresponsible adult visitor in the house poses a particular problem for 3D printer owners.

Filament is cool to the touch, it looks like a shiny cable, it makes cool whirring sounds when it moves, and it has a delicious color. You have probably seen what children or pets can do if they get their hands on a dull-looking roll of toilet paper, now, imagine what they will do to a shiny cool looking roll of filament. Therefore, its best to keep your filaments away.

Sun Damage

As we’ve already established, most filaments are not UV resistant, and exposure to the sun will probably damage them over time.

Sometimes, your filaments may look fine but you can actually feel or see that the PLA or ABS material feels softer or brittle, thinner, and more pliable. And worst of all, it could potentially have deformed to the point where it’s so brittle that it could easily break off or snap.

Sun damage mostly happens while the filament is being transported or stored near a window. It is certainly easy to avoid this issue.

The spool is either too loose or too tightly held by your printer’s spool holder

A very common problem with 3D printing is when the spool holder has such friction that the spool can not move easily while printing, causing issues like weak layers, poor adhesion, or even clogs and jams.

To avoid this, make sure the spool holder can move freely and at the same time not cause any hindrance to the rotation of the spool when the printer pulls from it.

Not using a filament guide

A filament guide almost always consists of a Teflon tube. Using it to feed the filament to your printer can help keep your filament from getting tangled up and gives you a little more peace of mind while you are working.

It can be very helpful for improving the quality of your prints by making sure that the 3D printer is extruding the filament straight and keeping it from getting tangled.

Conclusion

Having gone through each one of the possible problems, we can conclude that most of them are not only avoidable but quite easy to prevent.

Be sure to implement these recommendations in your usual printing flow and always take a few extra seconds to properly store your filaments.

Check out our recommended products section

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

Error processing API data.

Hello, please how to choose the right PLA filament for my 3D printer, i mean is there any advice to follow for the right pla ???