FDM and Resin printers are the two most common types of 3D printers currently available on the market for hobbyists and home 3D printing enthusiasts and, even though they both are 3D printers, they couldn’t be more different from each other.

Knowing which one to get is something I feel is extremely important since you want to get the right machine for your specific needs, since they work very differently.

In this article, we will go over what 3D printing is all about, the differences between FDM and resin 3D printers, which one is more suitable for each use-case, the costs associated with them, and more!

The short answer is: FDM printers use a plastic filament as the printing material which is melted and deposited to create the object layer by layer, while resin printers use a liquid resin which is cured, usually layer by layer, by an ultraviolet light which hardens it. Resin printers have a much higher print quality than FDM printers but this comes at a higher cost, both in terms of purchase price and cost of running the machine.

What is 3D Printing?

3D printing consists of a process that starts with the digitization of an object, which can be designed with the help of a computer aided design (CAD) software, which then lets you materialize that digital model via the use of a 3D printer, be it FDM, any of the resin printers, or any other kind of printer.

Once the design is created, you need to Slice it using a Slicer software, which is designed to “Slice” or “cut” the model horizontally into multiple layers and then outputs that information in the g-code format.

The printer can then use that information to print the model layer by layer, starting at the very bottom, printing that entire layer and then moving up to the next one, and so on.

FDM Technology

This technology, also known as FFF (Fused Filament Fabrication), consists in using a thermoplastic polymer filament which is pushed through a nozzle which is extremely hot, approximately 200 degrees Celsius, which then melts and deposits the plastic on a flat surface, known as a bed, layer by layer.

Resin printers – Photopolymerization in a vat

Resin printers work in a similar fashion to FDM printers, in the sense that they print layer by layer, but everything else is quite different: The process consists of a vat filled with photopolymer resin which polymerizes when exposed to ultraviolet light, solidifying and forming a thin solid layer.

The mechanism contains a laser that emits light, which is deflected by a mirror into the vat and draws the layer to be printed in two dimensions. It also has a platform that will move from bottom to top where the object will be “attached” to, similar to the bead of an FDM printer, only upside-down.

This technology is known as stereolithography, or SLA.

There are other technologies that use the same phenomenon of polymerization via the action of ultraviolet light, which are : Digital Light Processing, or DLP, and MSLA (Masked Stereolithography).

DLP is based on projecting the image of the part in its entirety. This projection is done through an array of moving mirrors that project the entire image onto the resin, making the whole process faster.

MSLA, or also known as LED-LCD, is an innovation of DLP technology where the mirror array is replaced by an LCD device, which has the function of blocking or allowing light to get through which will then solidify the resin.

Differences between filament and resin printers

As you may have seen in the brief description of both technologies, they work in completely different ways and use different materials as well: FDM uses filament which melts and sticks to the previous layer, gradually forming the model, while SLA, DLP, etc., use resin which is cured with ultraviolet light.

Now let’s look at the differences between print quality, the durability of the parts they produce, the costs of having one or the other, and more.

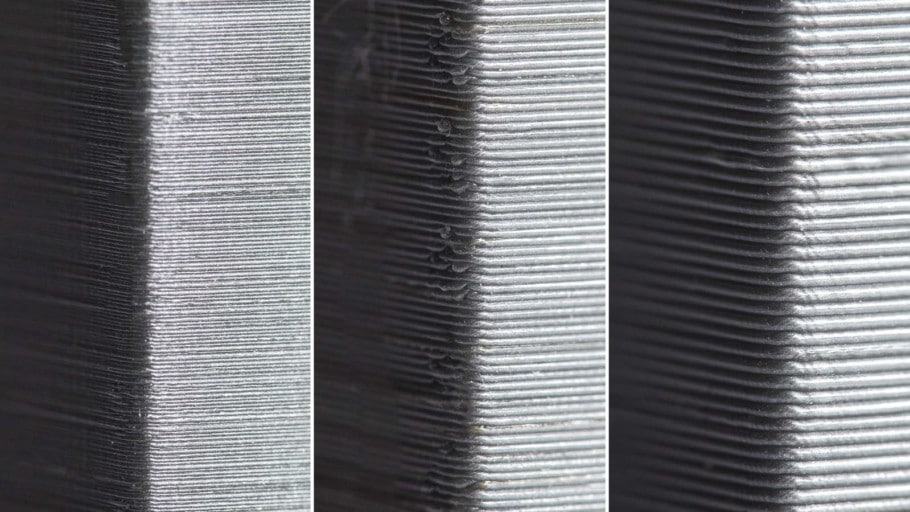

Print quality

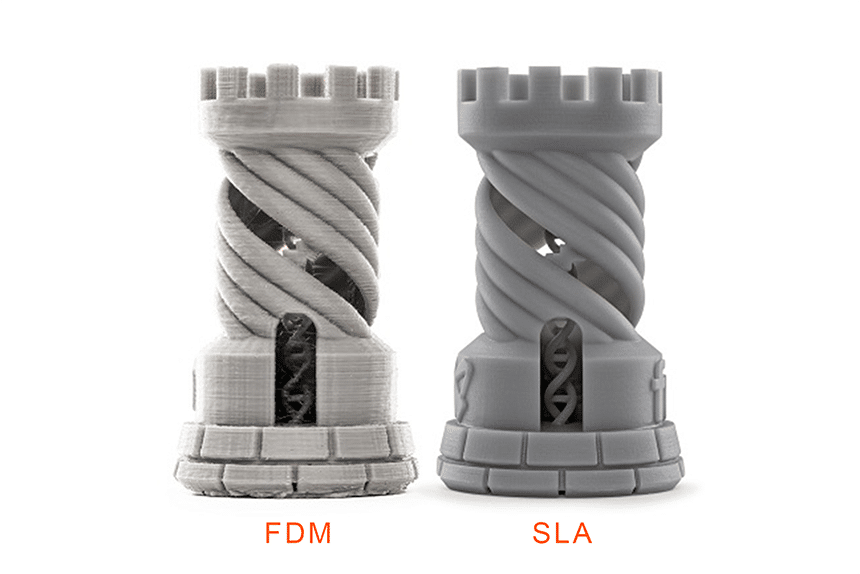

What immediatly stands out when looking at the prints created by resin printers is the quality and precision in the construction of the parts.

If we refer to the technologies described above, we can infer that, in the case of FDM printers, the layer thicknesses are lager in relation to those of resin printers and, therefore, they won’t be able to produce prints with as much detail, which is especially noticeable in miniatures.

The final product from the resin printer has a more uniform finish with no visible seam lines that are common with FDM printing. Print quality is one of the most important differences between the two technologies, and resin printers actually produce much higher resolution prints.

Materials and durability of the printed part

One of the strengths, so far, of FDM printing is the variety of materials available on the market since you can find hundreds of different filament brands, types, colors, and more, but with resin printing you’re much more limited.

In addition to this, and in relation to the material, the overall strength of the models that come out of a resin printer is quite lower, not to mention that resin will degrade over time when exposed to UV light, making the part even weaker.

Lastly, when printing prototypes, since resin printers are not as capable of printing large models as FDM 3D Printers, you might find yourself quite limited and having to split the model, or alter the design entirely.

Build volume

The volume of the part to be printed is also a limitation, since the resin printer has smaller dimensions and therefore smaller print volume.

It should be clarified that we are talking about the consumer market, i.e. those printers that are within the reach of the majority, and not those that are aimed at a professional market.

Printing speed

The printing speed is higher with resin printers because the layer to be solidified is printed at once, so if we print several models, resin printers will come out ahead of FDM printers as far as speed goes.

Just like with FDM printers, if you need to increase the print speed even further, then you could adjust the slicer settings to increase the layer height, as well as adjust other parameters, to get the print to complete sooner. Just remember that printing faster usually means lower print quality.

Post-processing

At the moment of finishing the print, in the case of FDM, the part is generally done and ready for use. Although it’s worth noting that in a few occasions it is necessary to remove some support material or sand to it to call it “finished”.

On the other hand, resin printers aren’t that simple: the unprocessed resin must be removed in an isopropyl alcohol bath and the print must then be cured in an UV light chamber (or you could leave it out in the sun). Lastly, more often than not, supports will need to be removed as well.

Maintenance

Resin printers are more compact and have fewer mechanical parts to adjust, unlike FDM printers, which have elements that suffer wear and tear with use.

For example, you might run into a scenario where the nozzle gets clogged and you need to unclog it, or the belts might need to be adjusted or replaced, a piece of filament might fall into one of the cooling fans and jam it, etc.

Resin printers with DLP or LED-LCD technology, the LCD screen may get damaged and the FEP film, which is part of the resin tank, may also need to be replaced every now and then.

Overall, resin printers are more expensive to maintain because the parts that need to be replaced, even though not as often as the parts of an FDM printer, are much more expensive.

Ease of use and security

Resin printers are easier to use because there is no need to adjust the different parameters of the printer itself (bed leveling, belt tension, etc.), but special care must be taken because the resin is liquid and very toxic, therefore, you must be extremely careful when handling resin and wear the required protective gear.

FDM printers, o the other hand, use a solid plastic filament, which means that there’s no danger involved. However, FDM printers, especially cheap ones, require consistent maintenance and you may also need to level the bed every 5 or 10 prints.

Both thermoplastic polymer and resins produce gases that in some cases can be toxic, such is the case of ABS, which requires working in ventilated areas.

Additionally, in the case of resin printers and like I just mentioned, precautions must be taken because the material is liquid and relatively toxic, so you must work with gloves to avoid skin reactions, wear protective eye-wear, etc.

Cost

I will divide the cost into three components:

- Acquisition cost.

- Cost of material.

- Maintenance cost.

The adoption of the technology is reducing its cost as it becomes more widely available because of the supply growth. FDM is leading the way in this regard and clearly the cost of acquisition is lower, although resin printers for home use can be purchased from $250-300 and will only get cheaper over time.

Filament is also relatively affordable at about $20 per 1Kg spool.

On the one hand, resin printers need isopropyl alcohol, in addition to photopolymer, for the final curing and finishing touches and, as I rpeviously mentioned, resin is much more expensive than filament, about 5x as much, and you need to add the Isopropyl alcohol to the mix as well, so now the price of running the printer is even higher.

Lastly, the cost of maintenance is higher for resin printers because the parts that need to be replaced are much more expensive than those of an FDM printer, such as the FEP sheet, which should generally be replaced every 20 to 30 prints or when it shows signs of wear.

FDM printers, on the other hand, do not really require preventive maintenance but because they have many mechanical parts and often suffer damage that requires a significant investment of time.

Which technology to choose?

Choosing what printer to go with isn’t that simple, although if you value print quality over everything else, then I would recommend going with a resin printer, but let’s think this through for a second:

Firstly, we need to be able to clearly identify the problem we have to solve, and secondly we need to know our functional, or non-functional, needs.

Here’s a practical example:

Suppose we want to develop functional electronic devices on a small scale, requiring some kind of container to house the circuit and, at the same time, some additional functional mechanism.

I would suggest putting together a list of criteria where we can then weight the importance of the characteristics that we want our model to have and give each of them a value to better determine what printer to get depending on the results:

| Criteria | Value |

| Printing Speed | 5 |

| Accuracy | 2 |

| Print Quality (Resolution) | 3 |

| Size | 5 |

| Cost | 1 |

This is just a starting point that lets you think more objectively about the pros and cons of the different technologies and that allows you to come to a more reasonable conclusion.

At least for now, resin printers offer a much higher level of detail when compared to FDM printers and then can even print batches much faster. However, all of this comes at a higher cost, having to deal with liquid resin, purchasing and using protective gear, using IPA, etc.

Conclusion

Both technologies have their pros & cons as well as some distinguishing features. Now, what if resin printers become cheaper, offer a larger print volume, and variety of materials? Well, I think that’s going to happen in the next few years and resin printers will slowly gain a larger share of the market.

Without going into an exhaustive analysis of the evolution of light-curing technology in a vat, it’s clear to see that these printers have slowly but surely made their way into the market and also become cheaper and cheaper, and I think that the future of resin printing looks quite bright.

Currently, in the professional market, there are printers such as the Form 3L that solve part of the limitations presented in this article, but these are not reflected in the lower cost models or for home use since they are more expensive printers designed for larger operations.

Now, even though the future of resin printers looks very good, I really think that, at least for most people interested in 3D printing, FDM printers are better as they do not require the same precautions to run as resin printers, since resin is toxic and you have to be very careful when using it.

Error processing API data.