We have oftentimes heard about different types of filaments for different applications. While PLA is great for easily achieving great-looking prints, ABS is cheaper and can better withstand high temperatures, PETG is usually better both in terms of tensile strength and impact resistance, and temperature resistance as well (compared to PLA).

Now, you might have also heard about PLA+ and may be intrigued about what it really is and what it is good for.

PLA+, as the name suggests, is mostly based on regular Polylactic acid, but also incorporates different additives geared towards improving tensile strength, temperature resistance, impact tolerance, to prevent moisture absorption, and improve the quality of overhangs, among others.

There is no consensus regarding the composition of PLA+, and each manufacturer tends to have its own formula that is usually not fully disclosed.

What is PLA+?

PLA+ is essentially a reworked version of standard PLA where additives or pigments have been introduced to the formula to enhance the characteristics of standard PLA. Judging from what is currently available on the market, PLA+ does not constitute a standard formula as the various vendors hold their “+” ingredients secret.

Each manufacturer has designed their own formula of PLA+, and because the process is a trade secret, PLA+ has fast become a manufacturer standard and not a universal standard like most other filament types.

This begs the question, does PLA+ still conform to its biodegradable standard, or has it been sacrificed for better print characteristics? The core ingredient remains standard PLA, but the additives will more than likely not conform with biodegradable standards.

Standard or normal PLA absorbs water and is gets brittle fairly quickly, but PLA+ has improved on these weaknesses and is stronger, less brittle, more durable, and has better layer adhesion.

PLA+ is seen by many as a filament that fits in-between standard PLA and ABS, which speaks volumes about the changed characteristics being more print-friendly and versatile.

PLA+ vs regular PLA

PLA+ is very similar to PLA in many ways; however, due to the altered manufacturer formulations, PLA+ does not have a standard or uniformed formula, so defining the differences has to be from the standpoint of standard PLA.

Manufacturers have tried to conform to standard PLA printing requirements while improving print quality in the process. Here are some noticeable differences between PLA+ and standard PLA:

- The surface texture of PLA has a coarser finish on the surface of the layers as well as the outer part of each layer.

- There is less stringing with PLA+ prints, and the overhang properties have been improved.

- The print temperature of standard PLA+ is slightly higher than standard PLA

- PLA prints tend to be more of a matte finish, whereas PLA+ has a glossy finish and looks more aesthetically pleasing.

- PLA+ tends to have a degree of flexibility, while PLA is more rigid and breaks under pressure. Numerous tests have been conducted on different PLA+ brands and standard PLA, which all confirm increased temperature resistance by up to 15 degrees C and it also performed better in tensile strength tests, as well as other tests.

Surface texture of PLA+ and PLA

Regular PLA tends to have a rougher finish on the final print. PLA+ offers a smoother and more glossy finish that can only be achieved with standard PLA when post-processed.

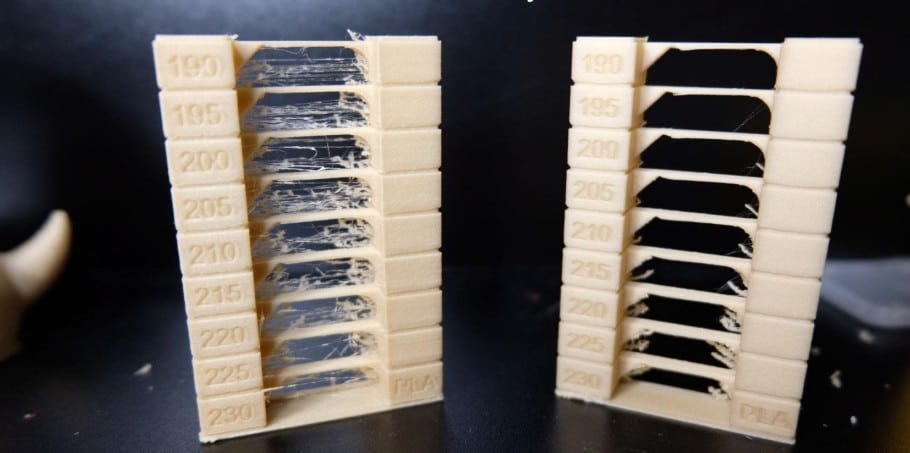

PLA+ vs PLA for overhangs

PLA+’s improved strength means you can expect improved quality with printing bridges and overhangs. It’s logical to assume that it will support its own weight better than with standard PLA because the material is stronger.

However, with printing overhangs, the results will not be consistent between manufacturers, so it will be up to you to either do some research or experiment independently. What you can generally expect from PLA+ is achieving angles of 65 degrees without your print deforming.

As we can see on the image above, the same part printed with PLA+ (on the right) features higher overhang quality. By this, we mean that PLA+ tends to allow for greater angles without the need of supports.

Printing temperature of PLA+ vs PLA

Due to the additives that make up PLA+, higher temperatures are generally required for printing; for example, eSun’s PLA+ recommends extruding at 205-220°C, whereas normal PLA is usually in the 190C°-215°C range.

You can see that the temperature difference is not that great, but it’s still big enough to affect the printing process and desired finish. A temperature of 215°C is a good starting temperature in the switch from PLA to PLA+.

As always, when changing to a new filament type (or brand), it is recommended to start tweaking the settings until you find the optimal parameters for that thermoplastic. When it comes to extrusion temperature, I recommend starting with higher temperatures and gradually lowering them in order to avoid clogging the nozzle.

This temperature tower from Thingiverse is an excellent way of finding the perfect temperature setting since it will print it region at a slightly different temperature and allow you to see the results for yourself.!

Reflection of PLA+ vs PLA

As stated, PLA+ has a glossier finish, and this can be observed across different manufactures.

Here again, you will have to do your homework to select a PLA+ filament that will produce the results you are after. But, some tests find standard PLA to be glossier than PLA+, so it seems tests must be conducted on specific manufacturer PLA+ filament to reach a conclusive finding which may still be viewed as subjective or biased for a number of reasons.

Impact strength of PLA vs PLA+

PLA+ can withstand more impact than standard PLA. In a test conducted to compare the impact strength of PLA+ and standard PLA, the results were not surprising at all.

Standard PLA absorbed an average of 5kJ/m² before it snapped clean through, while PLA+ registered an average of 20kJ/m2, four times as much as standard PLA.

With the PLA+, the test sample snapped but did not break all the way through.

Is PLA+ stronger than PLA

Strength tests to compare PLA and PLA+ in this dimension are not justified since they behave differently. While regular PLA tends to break at certain loads, PLA+ starts bending instead.

A strength test can be conducted against a specific print function. For example, printing hooks that are designed to carry a load. Both will fail but in different ways; the PLA hook will snap at its maximum load while the PLA+ hook will be stretched out and either partially break or simply drop the load from the stretching out of the hook. Nonetheless, generally speaking, PLA+ tends to have improved strength qualities.

PLA+ vs PLA price

PLA+ is seen as an improved version of standard PLA, and because of the cost of the additives and manufacturing processes, it is natural to presume (and correctly so) that the price will also be higher.

While regular 1kg spools of PLA cost between $15 to $20, PLA+ spools are in the $20 to $30 range. The price difference can, however, be justified if you weigh in the improved characteristics of PLA+.

Homogeneity of PLA+ and PLA

Printing with different PLA brands doesn’t generally require altering or modifying some parameters in the slicer to adjust to subtle changes in the composition of the thermoplastic, like pigmentation and purity, only in rare cases.

This is different for PLA+ as manufacturers introduce different additives to their “secret +” formula, which, as is common knowledge in the 3D printing community, differs from manufacturer to manufacturer. Each manufacturer manipulates standard PLA to improve certain characteristics.

This is why with PLA+ you’ll probably need to adjust the settings with each different spool you buy.

For this reason, if you are hooked on PLA+, finding a good, reliable manufacturer and sticking with them helps you in achieving consistency in your print quality.

Moisture Absorption of PLA+ vs PLA

PLA is one of the most Hygroscopic filaments used in 3d printing.

By definition, PLA+ is still predominantly made up of standard PLA so, although some manufacturers claim that their PLA+ is more moisture-resistant than regular PLA, you should question the claim and not use PLA+ if moisture resistance is important.

It will be better for you to consider using ASA if you are specifically looking at water resistance.

Does PLA+ withstand higher temperatures than PLA

The question is best answered by doing a comparison test using a print built from standard PLA and one built using the specific PLA+ filament of your choice. PLA+ is still considered a filament that is a work in progress.

A test was conducted with Polymaker material and Polylite PLA, and the results confirm that PLA+ is composed mostly of standard PLA ingredients.

Two bars with weights suspended on them were placed in an oven, and the temperature was monitored and slowly increased. At 60°C, both bars had become soft and unusable, and at 65°C, both bars simultaneously failed, which is what can be expected from standard PLA as it falls in with its glass transition temperature.

The result of the test indicates that PLA+ is no more heat resistant than standard PLA, but as stated, PLA+ is a work in progress, and the thermal qualities of PLA+ will more than likely improve in the near future.

There is a possibility that this has already been accomplished to a degree (excuse the pun) with the use of crystallization modifiers or other co-polymers that improve the heat-resistant properties of PLA+.

Is PLA+ easier to print than PLA

Tests conducted to compare PLA and PLA+ showed some rather expected results, yet some findings were surprising. Warping with PLA+ appears to be reduced, and this could be as a result of the first layer and subsequent layer adhesion, making printing with PLA+ a little easier, especially with parts that are prone to warping.

For both PLA and PLA+, the nozzle temperature is set to 215°C, but it is not necessarily the best temperature for some tough PLA filaments. During printing, standard PLA showed a bit more stringing, yet in other previous tests, it was the other way around. However, both materials did well with fine details on the print, and bridging was no problem either. The results are, to say the least, a little ambiguous.

I think it is worth mentioning that regular PLA is already the easiest filament when starting out, making it the most popular go-to choice for both beginners and pros. It should come as no surprise, that PLA+ is not consistently easier to print, since it is not a characteristic that is actively demanded by the community.

As we’ve seen in previous sections, most manufacturers focused (and succeeded) on improving other technical characteristics of PLA+. I should also go back and remind us that it tends to produce better overhangs, which I also translate as making it easier to print!

The tests showed that the performance of both PLA and PLA+ are very similar, and the advantages of PLA+ can be selected for specific print purposes.

If you want to try out some PLA+, or if you want to compare both PLA and PLA+ yourself, you can get a spool of each of one here: PLA+, Standard PLA.

Conclusion

Having gone through the most relevant dimensions by which we usually try to rank different filament types, I think it is safe to say that the applicability of PLA+ should not be understated. If you are willing a few extra bucks and came across a brand of PLA+ that yields great results, I would definitely suggest that you stick to it.

Maybe I have a low tolerance to frustration, but I really value a filament that yields good results in a consistent and replicable fashion. I’m also willing to spend an additional dollar or two in order to get my hand on such a thermoplastic. If you can relate to that, you should definitely consider trying out a spool of PLA+.

Check out our recommended products section

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

Error processing API data.