In this article, I will be going over the different types of printers there are as well as their price range. I will be covering both FDM and Resin printers.

However, if you’re new to 3D printing you might not know the differences between an FDM printer and a Resin printer, so here’s some information that might help you out!

If you want to skip straight to the different printer types and their prices, click here.

So, are 3D printers Expensive? The average desktop printer will set you back between $200 and $1000 depending on the number of features it includes, the overall print quality and the materials it’s able to print with. The price of Filament ($20 for 1KG Spool) and Resin ($80 for 1000ml) also has to be taken into account when considering the overall printing cost.

Difference between FDM and Resin Printers

3D printing technology encompasses many types of products, but they generally fall into two categories: FDM and Resin printers. They use different materials and have diverse applications.

The Fused Deposition Modeling (FDM) printer is the most mature of the two and is usually cheaper. It works on the same basic principle as a hot glue gun; you feed it with a plastic filament, and it melts the plastic, which then cools and gets solid.

FDM technology was developed by S. Scott Crump, one of the founders of Stratasys, as a new technique for creating prototypes from 3D models. It is an additive manufacturing process, typically creating parts by laying down many thin layers of material until the full shape is formed.

It is a versatile and affordable technology that allows you to 3D print objects in almost any color and in a variety of engineering plastics. FDM is also ideal for rapid prototyping and producing end-use parts. It has many applications and benefits, it is most widely used in the consumer and enthusiast market as an affordable manufacturing technique.

Resin 3D printers and resin 3D printing are two of the newest advancements in the world of 3D printing. Having been around since 2009, this group of printers has increased in popularity, expanded their manufacturing capabilities, and improved greatly over the years.

The core technology for resin 3d printing was developed by Charles Hull in 1986 when he invented stereolithography. Hull improved upon a technique that had been around since 1980 by making it faster and more efficient.

Instead of using a raw filament of plastic, resin printers use a resin (also called photopolymer) that hardens into a solid when exposed to UV light.

In simple terms, they are advanced full-color stereolithographic printers in which basically, a light draws a picture on a tray of photosensitive resin, and then builds a picture up layer by layer until it has produced the whole object.

Both SLA and FDM are rapid prototyping methods. But the similarities end there: SLA and FDM are two different technologies that produce different kinds of results. There are also fundamental differences between the materials commonly used in each technology, as well as between the range of colors available with each method.

SLA provides high-precision, clean STL files in a small work envelope, while the second is more suited for rapid prototyping. Because the resin used in SLA printers has to be transparent for UV light to pass through it, the objects printed by SLA are transparent (they can be colored, but UV light needs to be able to penetrate them) but also somewhat flexible.

While accidentally touching the hot nozzle and flatbed of FDM printers can cause mild burns, the toxic resins used in SLA printers can cause you serious harm if they touch your bare skin or get into your mouth, nose, and eyes.

This is one of the main reasons that SLA printers are enclosed in a transparent casing and require ventilation, unlike FDM printers.

SLA printers are also a lot less noisy compared to FDM printers because they have fewer motors and moving parts.

The most significant difference between SLA and FDM is that the objects made with SLA are smooth and have a fine surface, produced directly by the liquid resin; while FDM printed objects have a rough surface that has to be manipulated by some tools after printing.

In general, SLA printed pieces look more like industrial injection molded parts than FDM printed parts because they do not require sanding or other finishing.

A standard filament in FDM printers can cost up to $25 per KG. The filaments are generally made up of ABS, PLA or PETG plastic.

SLA printers cost a lot more money to operate. The first reason is that the resin itself is quite expensive. Depending upon the manufacturer and the model of your printer the resin can cost anywhere between $80-$150 per liter. The resin tank also needs to be replaced regularly after every 2-3 liter consumption of the resin and it can cost between $40 to $80.

If you want an In-depth price comparison between filament and resin, then check out this article I wrote!

So, even though resin printers might be a lot more precise and better at printing fine details, the cost of operating them will be much higher.

Now that that’s out of the way, let’s take a look at the actual prices of the different kinds of printers.

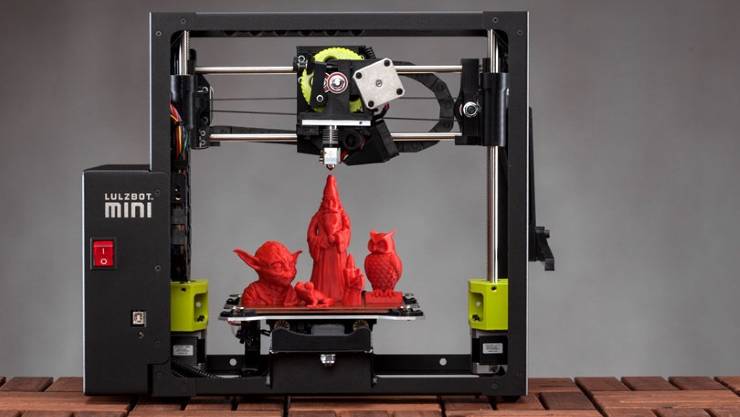

Entry Level and DIY Printers (under $300)

These relatively inexpensive 3D printers are for those who are looking to get their feet wet in the world of 3D printing. You will be able to buy a decent entry-level DIY 3D printer between $200 to $300. I won’t recommend buying a printer that costs less than $200.

Note: SLA 3D printers are generally not available in this price range.

The reason these FDM printers are called DIY FDM printers is because when you open the box, you will only find unassembled parts and you will need to assemble the printer yourself.

Now, you don’t have to worry if you are not good at solving puzzles, these types of printers are so simple to put together that it should take you no time at all.

These printers can also be quite noisy, they can only print small objects, usually have a slow speed of around 100MM/s and the quality of prints can also be severely compromised. You will have to calibrate them yourself and they require regular repairs. They also need to be modified before they can use PLA or other special types of filaments.

The main advantage of DIY 3D printers is that they are highly modifiable and a DIY enthusiast can modify them to match the performance of high-end professional 3D printers.

The Ender 3 v2 is by far the best 3d printer that you can get in this price range. The quality of prints that is achievable with this budget printer is comparable to printers that are well above this price bracket.

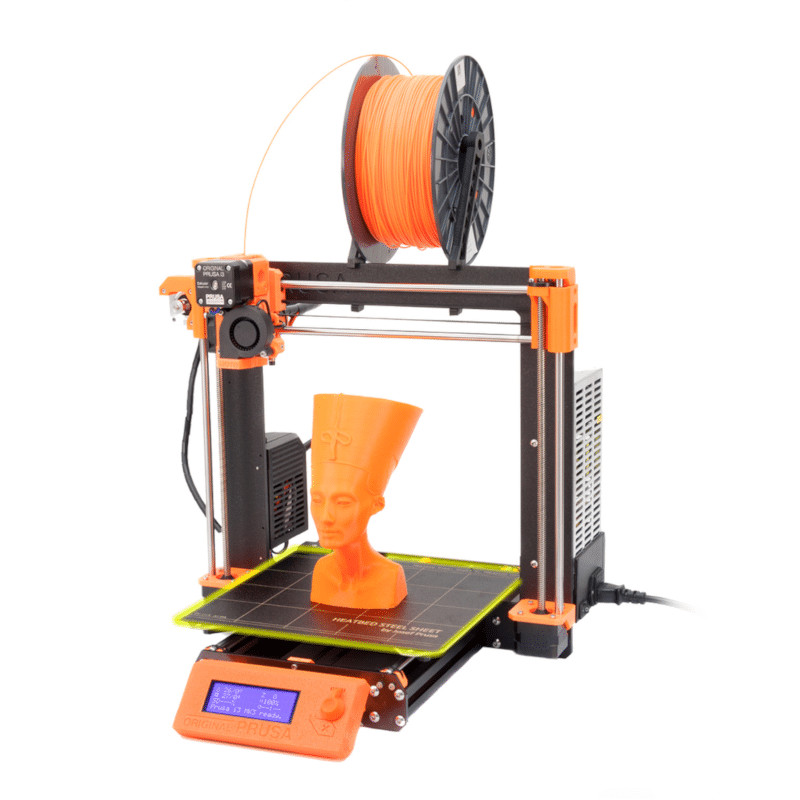

Hobbyist Printers ($300 – 1000)

Entry-level, and DIY models are usually the most affordable of the 3d printers (under $300), but that doesn’t mean you should compromise on quality. When it comes to choosing a printer, it’s important to find something durable and reliable like Hobbyist Printers that cost between $300 – $1000.

Hobbyist printers typically offer everything that a serious hobbyist or casual enthusiast would require in terms of features and overall value.

They mostly come pre-assembled but may need initial calibration. But unlike DIY printers, they operate smoothly without requiring regular calibration, repairs, or maintenance.

Printing speed, quality, and volume (the ability to print bigger objects) improve as you climb higher in the price range. The high-end models will also be able to use other types of filament, such as metal or wood infill plastics without requiring modifications.

Entry-level or budget SLA (Resin) printers are also available in this price range but you should only get them over reliable FDM printers if you are looking to print designs that require intricate detail and smooth surfaces.

But these budget SLA printers are perfect for toy or jewelry makers as they can make casting molds of small objects. These printers can offer great value for money.

The cool thing about resin printers is that you can actually mix different resin colors, use pigment to change the color of the resin, etc. to create more interesting prints.

The most reliable printer that you can get in this price range is definitely a Prusa Printer. Prusa not only is one of the best known and most reputable brands in this space, but they run a printing farm consisting of more than 500 Prusa printers working simultaneously. By working intensively with their own products, they are capable of constantly finding new ways to improve their machines.

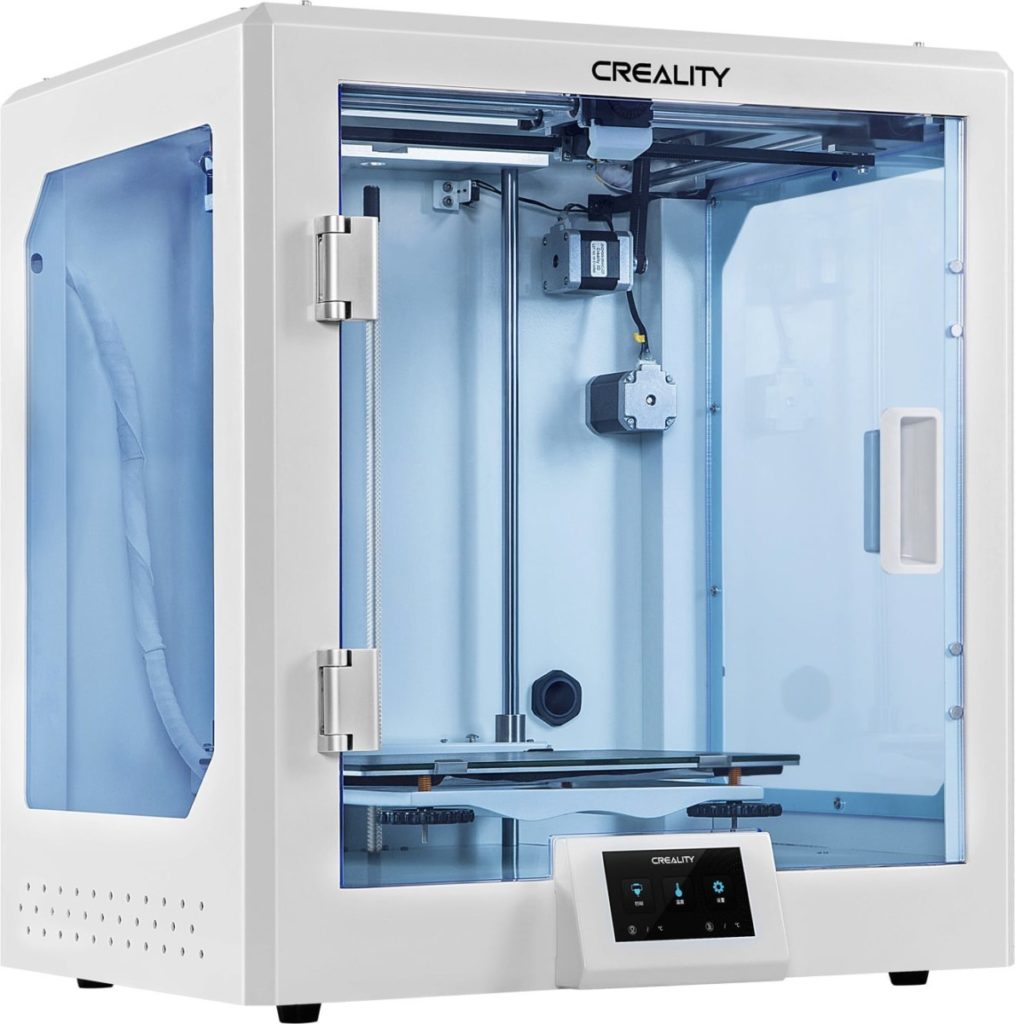

Enthusiast Printers ($1000-3000)

Enthusiast printers have real power and versatility at a price that won’t break your bank…. well, I don’t know about that, but they will allow you to get some really good 3D prints done right in your garage or lab.

FDM printers in this price bracket are not much different than the ones in the hobbyist price bracket except that they have improved print quality, speed, and volume. They also have better build quality and reliability. SLA printers in this category can also print high-quality objects with far superior precision and intricate details.

Both SLA and FDM printers can have enclosures, which isn’t a common feature in most FDM printers, and this will allow you to print with ABS more easily, they offer auto-calibration, touch screens, Wi-Fi connectivity, software with regular updates, and even a user-friendly interface.

Other than enthusiasts, these printers are also well suited for architects or industrial designers thinking about going into production with their proprietary designs or logos for gifts to clients, these printers are a great investment.

Professional Printers ($3000 – 10.000)

These printers are not the rugged little hobby-horse kits you pick up for basement printing projects.

Because they are expensive, you can bet that these printers were heavily researched and iterated upon multiple times before a manufacturer thought about putting them out in the world. Hence they have bulletproof reliability, bug-free software, enhanced user interface, and after-sales service or warranty in case of any malfunctions or hardware failures.

You can also expect a native app that lets you remotely monitor and control the printer.

In FDM printers, you can expect the noise level to be considerably lower due to the presence of an enclosure. But in larger models, the noise will still be pretty loud. They should also be able to double and triple as laser engraving or cutting machines or CNC.

SLA printers will have higher levels of precision, and hence engineers working at industrial manufacturing will be able to use them for prototyping. Also, they don’t have as many moving parts as FDMs so they will be considerably quieter.

The main downside of these printers is the operating and maintenance cost. The consumable items like filaments and resins will have to be purchased from the original manufacturer at a higher cost, otherwise, you may expect the printer to reject the materials, or run into other issues.

The maintenance and parts replacement can also be expensive after the warranty period has expired.

Industrial Printers ($10.000 – 100.000)

These printers are the gold standard of professional engineering applications, and they cost almost as much as a mid-size sedan. These are designed strictly for industrial applications and they have multiple large separate units, each with its purpose e.g. printing or curing.

Not only do they cost a lot, but they are also expensive to operate and maintain and it’s quite normal to pay huge sums of cash to the original manufacturer for the after-sales services. The engineers or designers might have to complete training to learn to operate these printers.

Industrial printers can also be expected to be industry-specific. You might have seen the printer that can 3D print a car and a printer that can 3D print a house. Expect to churn out anywhere from $10,000 – $100,000 for an industrial printer.

Filament and Resin Costs

While the 3D printer itself might be where the bulk of your initial investment is going to end up, you have take into consideration the cost of the materials used to print with, as well as some other costs associated with resin printers, such as purchasing protective gear, isopropyl alcohol to cure the prints, and more.

Here’s a table with a quick rundown of the costs;

| Printer Type | Printer Price for the average Hobbyist | Filament/Resin Price | Other Expenses | Recommended for | Advantages | Disadvantages |

|---|---|---|---|---|---|---|

| FDM Printer | $200-$1000 | $20 per 1Kg Spool | Some minor Repairs | Beginners and people who don’t need a high level of detail. | More affordable to run. Non-Toxic. | Loud. Lower print detail. |

| Resin Printer | $180-$900 | $15-$45 for 500ml $28-$85 for 1 Liter | -Changing the Resin Tank ($40) -Protective Gear: $45-$65 -Isopropyl Alcohol: $30 -UV Lamp: $30 -Some Repairs | Users who need high-quality prints with great detail. | More detailed prints (good for Miniatures) | Resin is toxic. More expensive overall. |

So, in short; the average cost for PLA, ABS and PETG is about $20 for a 1Kg spool, and for Resin you can expect to pay anywhere from $15 to $45 for 500ml of resin, and for 1000ml the price range is between $28 and $80

Conclusion

For most people interested in 3D printing, I’d recommend going with an entry-level or hobbyist type printer (between $300 and $1000) since these will yield great results and are also very cost-efficient.

Just remember that FDM printers aren’t as good at printing detailed models, so if you’re someone who wants to print perfect miniatures, for example, then maybe a resin printer might be the way to go. Just remember that those end up being more expensive over time due to the additional items you have to buy and the higher price of resin when compared to filament.

I hope this information was useful and as always, have a wonderful day!

Check out our recommended products section

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

Error processing API data.