A heated bed is the base that you print your 3D models on, with the one characteristic of also being able to be heated, which can be advantageous when using certain kinds of plastic.

Although not all 3D printers have a heated bed, it is required when printing with certain materials, like ABS, for example.

In certain situations, the material to be printed would require a heated bed to avoid lifting at the edges of the print, also known as warping, and this helps keep the temperature of the extruded plastic consistent throughout the duration of the print and prevents it from rapidly cooling down.

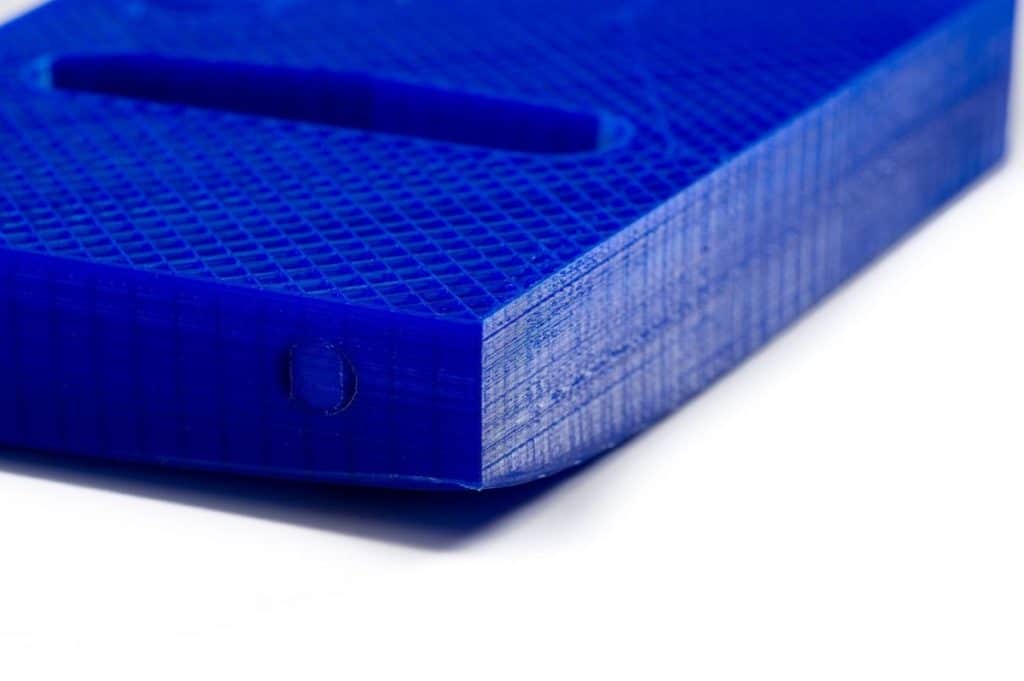

Image Source: Ultimaker.

Warping occurs due to the material shrinking while 3D printing, which causes the corners of the print to lift and detach from the build plate. When plastics are printed, they expand as they are heated up and printed but contract as they cool down, which causes the print to bend up from the build plate.

So, in short;

The advantage of using a heated bed is that it improves the overall quality of your prints by preventing the extruded plastic from cooling too quickly, which can lead to warping at the sides and corners of the model because it cools down too fast and unevenly.

Now, not all materials behave the same, which is why they need different printing conditions to be met to avoid this issue, and temperature is the most important factor since it’s what determines whether the plastic is allowed to warp or not.

This isn’t such a big issue when printing small models, but when printing larger 3D objects, even when the first layer adhered properly to the bed, the twisting and curling that occurs on the latter layers might end up detaching your model from the bed anyway.

This process mainly occurs when printing big or long parts with high-temperature materials, for example, ABS. The primary driver behind this issue is the way that plastic behaves as it cools down. For instance, if you print an ABS part at 230oC and immediately allow it to cool to room temperature (25oC), it will shrink by roughly 1.5%.

Imagine having this happen on a larger-scale model and on each layer, where every layer will start to twist until all that force detaches your 3D model from the bed. This, over time, will end up causing you to have a lot of failed prints and wasted material.

Heated beds work by regulating the temperature of the bottom part of the print, which prevents warping. They provide improved adhesion of the first layer allowing the print to stay flat.

Of course, there are many different types of heated beds that all work slightly differently and are designed to be used with specific materials, but more on those at the end of this article.

Even though heated beds work extremely well to prevent warping and to get a better first layer adhesion, there are other ways you can avoid these unwanted side-effects if you don’t have a heated bed; by adhering other materials on-to the bed itself to serve as the printing surface, such as Painters tape, Kapton tape, Hairsprays, and Glue.

Common Warping Solutions

- Use a Heated Bed.

- Disable fan cooling.

- Use a heated enclosure.

- Use brims and rafts.

The common denominator here as you can see is temperature control, and a heated bed would work quite well since it’s designed to regulate the temperature of whatever plastic you’re using.

However, like I previously mentioned, warping is especially problematic when printing with ABS, and therefore, understanding the recommended or optimal temperatures of various plastic materials, and ABS in particular, is very important, which is why I urge you to read the next part where I go into detail on what temperatures to use with each filament.

Note: You can check the label printed on your Filament spool to know the ideal printing- and bed temperatures.

Recommended temperatures

The different filaments used to print, such as ABS, PLA, Nylon, PETG, RE-Pet, Tech-G, PolyFlex, Carbon Fiber, etc., have different physical properties and would require different printing- and bed temperatures, as well as a different bed adhesion material.

In addition to this, how difficult they are to print varies quite a lot between each material, as does their overall strengths, which is why they are useful for different applications, but for the sake of this article, let’s talk about ABS since it pertains more to the subject at hand.

What is the Glass Transition Temperature?

The Glass Transition Temperature is the temperature at which a polymer becomes viscous upon heating; It takes on a glassy-state giving it mechanical properties such as brittleness, stiffness and rigidity, more commonly known as going from a solid state to a more “rubbery” state.

Different plastics have their own glass transition temperature values; ABS has a minimum and maximum value of 90oC and 102oC respectively, which is far below the print temperature leading to warping. For this reason, the heated bed temperature is set at a range of 90 to 100oC to harness the glass transition period.

PETG, for example, has a glass transition temperature value of between 70oC and 80oC, resulting in a bed temperature range of 70 – 80oC.

ABS is quite difficult to print since it shrinks remarkably as it cools down, which is the major cause of warping.

The layers of an ABS 3D print may separate (delamination) or even break because of the interior pressure building up during the part’s cooling.

Here’s a very useful table that you can use to determine both the printing temperature for your type of plastic as well as the bed temperature required.

Temperature Range Table

The table below shows the temperature ranges of specific plastics:

| Plastic | ABS | PLA | Nylon | PETG | PolyFlex | Tech-G | RE-Pet |

|---|---|---|---|---|---|---|---|

| Filament Type | Standard Filament | Standard Filament | Standard Filament | PET Filament | Flexible Filaments | PET Filament | PET Filament |

| Print Temperature | 210 – 250oC | 180 – 230oC | 220 – 260oC | 210 – 250oC | 195 – 255oC | 200 – 238oC | 200 – 230oC |

| Bed Temperature | 50 – 100oC | 0 | 50 – 100oC | 70 – 80oC | 50oC | 45 – 68oC | 30 – 70oC |

| Print Difficulty | Hard | Easy | Easy | Medium | Medium | Easy | Easy |

| Bed Adhesion | Kapton Tape | Hairspray | Kapton Tape | Glue Stick | Hairspray | Glue Stick | Glue Stick |

| Use | Ideal for mechanical parts | Ideal for prototypes and bio-degradable use case | Ideal for functional Parts | Ideal for food use | Ideal for parts that require good elasticity | Ideal for design engineering and architectural use | Ideal for plastic use cases |

So, now that you know more about why heated beds are useful and what temperature you should set them at for your prints, it’s time to dive into the different kinds of heated beds there are.

Types of Heated beds

There are a wide variety of heatbeds available and some of them come pre-installed with your printer (most of them, however, don’t come with a heated bed but rather a regular one).

Listed below are the most common ones;

PCB Heated Bed

Developed by Josef Prusa, PCB heated beds work by running an electric current through a conductor that produces heat.

These heated beds are utilized by numerous 3D printers not just because of how well they perform, but also because of how affordable they are, and the installation and levelling process is a breeze as well.

You can expect a straightforward and clean printing experience when using them, they require minimal vertical freedom when contrasted with a tempered steel sheet mounted with aluminum clad resistors, and they also provide an even heat dispersion.

Kapton Film Heater

Kapton is an electrically conductive polyimide film developed for heating applications where a thin, lightweight, uniform heater is needed.

Since these Kapton Film Heaters are so thin, they are capable of both heating up and cooling very quickly and are designed to be used with heating mediums that provide quick thermal dispersion so that the plastic materials can both heat up and cool down quickly to prevent twists and warping.

Aluminum Clad Heaters

Aluminum Clad Heaters have an electrical circuit that uses a thermistor and insulator in the case of temperature-sensitive elements.

They are found to be efficient and cheap, however, aluminum-clad heaters require quite the intricate installation process since they have to be screwed to the surface, and it is recommended to use paste between the clad heater and the surface.

This is why I’d recommend getting a printer that already comes with a heated bed since buying them separately may result in compatibility issues.

It’s worth noting that most 3D printers don’t come with a heatbed, therefore, check to make sure that the printer you end up getting already comes with one, like the XVICO Open Source Marlin2.0 Semi-Assemble DIY 3D Printer.

And last but not least…

Heated Bed Adhesives

I briefly mentioned earlier different adhesives that can be attached to the bed itself to help your prints to better stick to it, and while using a heated bed will help you out a ton, there may be times when you may need to resort to these types of materials.

Painters Tape and Kapton Tape are great forms of adhesive and are ideal for printing ABS due to their rough surface, improving adhesion.

Kapton Tape also works great with PLA since it will help keep the model stuck to the heatbed throughout the printing process.

Another type of adhesion are hairsprays and glues, which also work well with ABS to increase bed adhesion. However, hairsprays are recommended to be used on glass surfaces.

Check out our recommended products section

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

Error processing API data.