There is an endless amount of 3D printing terms out there. While some terms are very common and often used, some are not, thus it is easy to get lost in the terminology while reading. For that reason, I decided to make the ultimate glossary regarding any 3D terms.

In this article, I will give you a quick peek at every 3D printing term.

Filament Types

ASA

Acrylonitrile styrene acrylate (ASA) is a filament type originally created as an alternative to ABS with better weather-resistant conditions and less warping. ASA is UV resistant and has excellent mechanical properties, as it is rigid and impact resistant. Because of these properties, ASA is mostly used for outdoor applications. Printing with ASA should be done in well-ventilated areas as it produces toxic fumes.

ABS

Acrylonitrile butadiene styrene (ABS) is one of the oldest and most popular 3D printing filaments. It is a low-cost filament with high-temperature resistance and good durability. To properly print with ABS you will need a heated print bed or heated chamber as this filament is prone to heavy warping without adequate heat. Use in well-ventilated areas to avoid the fumes produced during the melting process (related article).

PETG

Polyethylene Terephthalate Glycol (PETG) is a semi-rigid 3D printing filament. Objects printed with PETG will have a shiny and smooth surface finish. Known for its durability and ease of use, PETG stands in the middle ground between PLA and ABS (the most commonly used filaments) as it is more flexible and durable than PLA and easier to use than ABS. PETG is hygroscopic, so keep it in a dry, cool place (related article).

PLA

Polylactic Acid (PLA) is the most commonly used filament in 3D printing. Printing with PLA is easy, as it melts with low temperatures and has minimal warping issues, thus making it great for beginners. Avoid PLA for outdoor applications as it has a low heat resistance and can deform when exposed to sunlight (related article).

Nylon

Nylon is a strong, durable, and flexible type of filament. Some printers will need an upgrade before being able to print with Nylon as it requires high printing temperatures and a heated bed to successfully print without warping. Nylon should be stored in airtight bags to prevent moisture absorption; if you don’t, moisture in the filament can lead to defects in the print.

HIPS

High Impact Polystyrene (HIPS) is mostly used as a dissolvable support structure in conjunction with ABS in dual extrusion printers. HIPS will dissolve in limonene and only the ABS will remain without any support marks. ABS is the only filament that doesn’t get damaged by the limonene. HIPS can also be used as a solo filament, it is lightweight and stronger than PLA and produces less warping than ABS.

PVA

Polyvinyl alcohol (PVA) is a filament used as support for complex prints in dual extrusion 3D printers. It dissolves in warm water, so it can be paired with many filaments, unlike HIPS that can only support ABS. PVA is highly sensitive to moisture so it should be stored in air-tight containers to keep the spool usable in the long run.

Flexible (TPE, TPU, TPC)

Flexible filaments (TPE, TPU, TPC) have rubber-like properties, meaning they are very elastic and can bend and stretch easily without breaking. These filaments are soft and durable as they have a high impact resistance. Bowden extruders might have a hard time printing flexible filament because it can stick and damage the PTFE tube (check out our article).

Carbon Fiber

Carbon fiber is used to reinforce other filaments to improve material properties. Filaments infused with carbon fiber show increased strength and stiffness. The result is a strong and lightweight material perfect for structural applications. These fibers are very abrasive and will damage brass nozzles fast, so consider using a hard material nozzle for these filaments.

Polypropylene

Polypropylene (PP) is a tough and durable filament. It has a strong heat resistance and produces smooth surface finishes. The problem with Polypropylene is that it is notoriously difficult to print with it because it is prone to heavy warping, and on top of that has poor layer adhesion.

Polycarbonate

Polycarbonate (PC) is one of the strongest 3D filaments; this filament is very strong, durable, and yet flexible. PC has also very good heat and impact resistance making it a solid option for rough environments. Most consumer-grade printers will need to upgrade the hot end to print with PC as it requires very high printing temperatures. PC filament is hygroscopic, for that reason it needs to be kept in dry spaces to preserve the spool’s integrity.

Conductive Filament

Conductive filament is capable of conducting electricity. This kind of filament is used for low voltage circuits. In most cases, PLA or ABS is the base material used in conductive filament, but they ain’t the only ones. Depending on the manufacturer, these filaments feature different values of resistivity.

Magnetic Filament

Magnetic filaments are PLA or ABS base filaments that were infused with iron powder. The result is a filament that acts like metal and is attracted to magnetic fields. It is an abrasive filament and a hardened steel nozzle should be used (check out our article on the topic).

Wood Filament

Wood filaments are typically PLA base filaments combined with wood fiber that look and feel like wood. This composite filament is less flexible and weaker than the normal PLA version. Also, nozzles can suffer and get damaged from printing this material (check out our article on the topic).

Material Related Terms

Glass Transition Temperature (Tg)

Glass transition temperature (Tg) is the temperature at which a material turns from a hard solid state into a soft, gooey state. Materials with low Tg like PLA are easier to manipulate as they don’t require high temperatures to process. Likewise, materials with high Tg will be able to withstand rough conditions as they are harder to deform (full article). It is measured in C° or F°.

Tensile Strength

Tensile strength indicates how much stress a material can take before it breaks. Whenever you print parts for strength and endurance purposes, go with high tensile strength filaments like polycarbonate (if your printer allows it). It is usually measured in Pascals.

Conductivity

Conductivity refers to the property or power of a material to conduct or transmit heat or electricity. It is usually measured in Siemens per meter.

Elasticity

Elasticity is the ability of a physical object to deform when enough force is applied to them and then return to its original size and shape when that force is removed.

Fatigue Strength

Fatigue Strength indicates how much stress a material can take for a given number of cycles without breaking. It is measured as the number of cycles of tension-compression.

Viscosity

Viscosity refers to the resistance of a fluid to change in shape, in other words, it measures the resistance of a fluid to flow. For example, water has a lower viscosity than honey. It is usually expressed in terms of centipoise (cP), which is the equivalent of 1 mPa per second.

Hygroscopicity

A hygroscopic material absorbs moisture from the surrounding environment. When these materials absorb the water molecules they can change physically, altering their properties. It can be measured by comparing the volume of an object in dry and humidified states.

3D Printer Parts

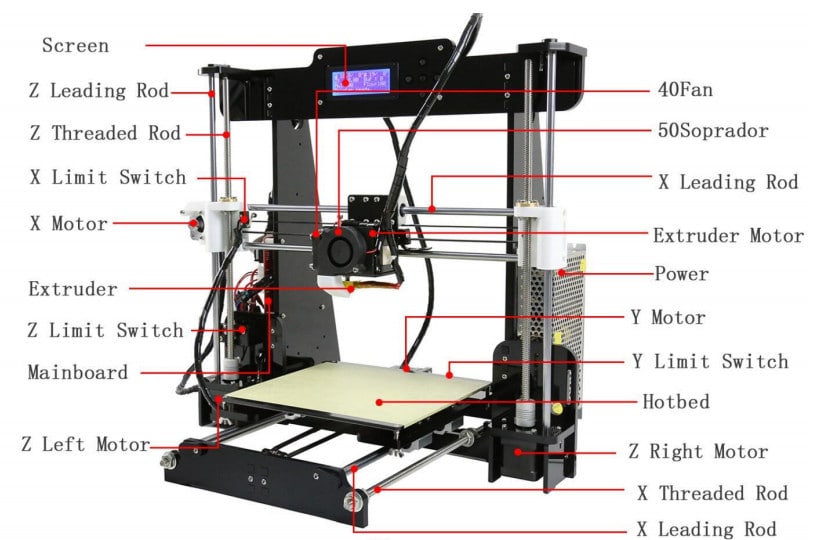

Controller Board

The controller board is the “brain” of your 3D printer. It handles all the electronic functions and requirements of a 3D printer. These printed circuit boards (PCB) receive the G-code from the slicer and translate them into commands for the 3D printer’s motors and heating components.

Extruder

The extruder is the part of a 3D printer that handles the moving and processing of the filament in order to deposit it in successive layers to form the 3D object. The extruder is composed of 2 elements, the cold end, and the hot end.

Cold End

The cold end is the part of the 3D printer where the filament is fed. There, the drive gears grab the filament and push it into the hot end. In direct-drive extruders, the cold end is directly above the hot end. Whereas in Bowden setups the drive gears are usually mounted on the printer’s frame.

Hot End

The hot end is the part of the 3D printer where the filament gets melted and then deposited in successive layers into the print bed. The filament is pushed through a non-heat conductive tube into the heater block where it gets melted and then pushed out the nozzle.

Nozzle

The nozzle is screwed into the heater block and is the last part of the hot end the filament travels through before being deposited into the print bed. Nozzles come in different diameters and materials, brass being the most commonly used and 0.4mm being the most popular diameter. Avoid brass nozzles whenever you are printing with abrasive filaments as they can get damaged pretty fast.

Bowden Tube

In a Bowden setup, the drive gears are usually mounted on the printer’s frame. From there, the filament is pushed through a Bowden tube into the hot end. The Bowden tube is generally made of PTFE plastic which is heat resistant and protects the filament.

Heater Block

The heater block is a part of the hot end and works as a thermal conductor. The heater cartridge heats the heater block which then heats the nozzle. Heater blocks are usually made from aluminum as it is an excellent thermal conductor.

Heater Cartridge

The heater cartridge is the element responsible for generating heat in a 3D printer. They are inserted into the heater block and produce heat from the electric current. The heat travels through the heater block onto the nozzles where the filament melts.

Thermistor

The thermistor is inserted into the heater block and it tells the 3D printer how hot the heater block is. This is important because different types of filament require different printing temperatures to successfully melt.

Cooling Fan

The cooling fan is a part of the hot end and in conjunction with the heat sink helps to dissipate heat. Without the cooling fan, the heat produced by high printing temperatures could travel outside the hot end and melt the filament before time. If the filament melts before entering the hot end you will likely have to deal with clogs.

Layer Fans

The layer fan is important to successfully print some filaments. It is located near the nozzle and aimed to cool the filament when it comes out onto the print bed. This way we help the melted filament to solidify faster and avoid deformation.

Endstops

The endstops tell your 3D printer how far it can move the nozzle through the X, Y, Z axis. Endstops are responsible for avoiding derails and jams on a given axis. The most commons ones are mechanical switches but there are also optical and magnetic ones.

Print Bed

The print bed is the surface where the 3D printer prints. Ideally, it provides a perfectly flat surface for your nozzle to extrude on. The print bed also gives the first layer a sticky surface to avoid the filament from detaching. Depending on the print bed material you might need to apply some adhesive to ensure the filament sticks to it. Glass print beds are the most commonly used ones but there are other materials with different properties.

X, Y, Z Axis Motors

The axis motors are responsible for moving the 3D printer’s nozzle across the different axis. To have a successful print, the axis motors need to properly move the hot end. Any malfunction on the axis motors will decrease the printing quality and speed.

Troubleshooting Terms

Warping

You have a warping problem whenever you see the filament curling away from the print bed while 3D printing. Warping occurs when the filament cools unevenly, as plastic contracts when it is cooling down. If the filament contracts too much it will lift and separate from the print bed. To prevent warping make sure the filament has good adhesion to the print bed. Some filaments are more prone to warping and require the use of a heated bed to avoid it.

Heat Creep

Heat creep refers to a problem in 3D printing where the heat travels upward outside the melting zone and starts to weaken and soften the filament before time. This issue causes the extruder to malfunction and can ultimately lead to clogs. To avoid heat creep try lowering the printing temperatures and make sure the cooling fans are working.

Bridging

Bridging in 3D printing is essentially an extrusion of filament suspended in the air that connects two columns. When a printer fails to bridge a small gap there is a bridging problem. Bridging problems are quite common; to solve this issue try increasing the layer fan speed, and decrease printing temperature and speed (related article).

Dimensional Accuracy

Whenever your printed object turns out to have different sizes than originally intended, you are dealing with dimensional accuracy problems. How well a printed object matches the size and specifications of the original file depends on many things. So before you start tightening belts and tweaking the firmware print a test cube to see how accurate your printer is. ABS is known for shrinking up to 8% when cooling down.

Ghosting or Ringing

Ghosting, ringing, rippling, echoing, all these terms refer to the unwanted presence of duplicated lines or features across the surface of 3D printed objects. This is caused by quick changes in speed and direction on the extruder which result in vibrations. To prevent this issue reduce printing speed and decrease the acceleration and jerk settings (full article on how to solve this issue).

Over-Extrusion

Whenever the 3D printer is extruding more filament than what the software thinks it’s called over-extrusion. Over-extrusion causes poor quality prints and can totally ruin a printed object. Possible fixes for over-extrusion are lowering printing temperature, decreasing the extrusion flow rate, and making sure the slicer has the correct filament diameter setting (full article on how to solve the problem).

Under-Extrusion

Whenever the 3D printer is extruding less filament than what the software thinks it’s called under-extrusion. Under-extrusion weakens the structure of the 3D printed object. If you see your model layers are too thin or have holes or gaps, you are most likely experiencing under-extrusion. In order to fix under-extrusion make the software has the correct filament diameter and increase the printing temperature and extrusion flow rate (related troubleshooting article).

Bed Adhesion

Bed adhesion refers to how sticky your print bed is. For a successful print, it is important that the filament sticks to the print bed. Bad bed adhesion can lead to warping amongst other printing problems. To prevent bed adhesion problems make sure the print bed is leveled and clean. If the problem persists, glue sticks and hair sprays can provide a lot of extra adhesion for the print bed.

Layer Separation

Layer separation has to do with the bonds between layers. For a successful print, every layer needs to adequately stick to the one underneath. Poor layer to layer adhesion can result in drastically defective prints. Layer separation is easy to detect as you will see gaps between the layers. Check out our article on the causes and solutions of this issue.

Clogged Extruder

A clogged extruder means your 3D printer can no longer extrude the filament properly. This is usually caused by an obstruction inside the nozzle. To prevent a clogged extruder make sure you have the correct printing temperature for your filament and that it is clean. Also, check that the nozzle is not too close to the print bed as sometimes there isn’t enough space for extrusion (how to fix a clogged extruder).

Gaps

Gaps are a common problem in 3D printing. You can have gaps between lines in the first and top layer or in between layers. Different solutions apply depending on where the gaps are (how to fix gaps).

Blobs and Zits

Blobs and Zits are small lumps on the outside surface of a 3D printed object. This happens at the spot where the extruder finishes printing a section of the outer shell and starts to print a new one. To prevent blobs and zits make sure you have optimal retraction and coasting settings in the slicer.

Weak Infill

The infill provides support for the structure of a 3D-printed object. A weak infill means the print can easily break. To avoid this issue use a strong infill pattern. If the issue persists lower the printing speed and increase the infill percentage (full article).

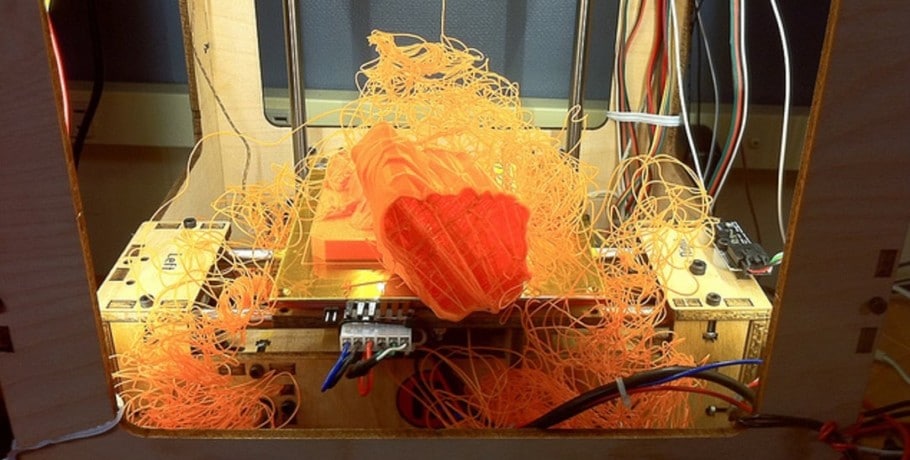

Stringing

When the extruder is moving through open space to a new location to print, some filament may ooze out the nozzle and attach to the printed object. This problem is called stringing and makes your prints look like they have cobwebs. To prevent stringing, lower the printing temperature and verify you have proper retraction settings (full article).

Layer Shifting

Layer shifting is an error in 3D printing where the printer malfunctions and misplaces the layers. Layers are being incorrectly positioned from one another, this can happen gradually or as one big displacement. This can happen due to excessive speed, and mechanical or electrical issues.

Overheating

Overheating is a problem in 3D printing where the filament is extruded at a high temperature and thus not able to cool down in time and retain the desired shape. Overheating can be fixed with proper printing temperatures and layer fans.

Elephant’s Foot

Elephant’s foot describes a 3D printing deficiency where the first layer of a 3D printed object is slightly larger than the rest. Sometimes the weight from the upper layers causes enough pressure to bulge the first layer if it hasn’t fully cooled. Elephant’s foot can be fixed by leveling the print bed, reducing the temperature of the heated bed, or adding a raft to the model (related article).

3D Printing Technologies

Stereolithography (SLA)

Stereolithography (SLA) is a popular technology of 3D printing. This technology uses a laser to harden a photosensitive resin in a layer-by-layer method. SLA is one of the most accurate 3D printing methods as it provides high-quality detail, tight dimensional tolerances, and smooth surface finishes. The downside is that SLA is usually slower, resins are fragile, and the components are expensive. For stronger prints, post-processing UV-curing is advised (related article).

Digital Light Processing (DLP)

Digital Light Processing (DLP) is a 3D printing technique that employs the light of a specialized projector screen to solidify photosensitive resin. DLP creates an entire layer at a time, which makes it faster than SLA. To achieve the desired shape, a digital micromirror device (DMD) located between the light source and the resin directs the light and creates the pattern of a layer.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is the most popular additive manufacturing method. It involves feeding the 3D printer with a thermoplastic filament which is heated past its glass transition temperature. Then, the melted filament is extruded on the print bed in a layer-by-layer fashion. FDM printers are cheaper than resin ones and can use a wide variety of materials to print with(related article).

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a rapid additive manufacturing method. This technology creates 3D objects by sintering fine polymer powder particles. After a roller spreads a thin layer of powder across the print bed, a laser heats the material and fuses it together. When a layer has finished printing, the print bed is lowered and another powder layer is laid down for the process to continue. This method does not require supports because the powder itself serves as support. Once the print is finished you need to remove the unsintered powder from the model.

Selective Laser Melting (SLM)

Selective Laser Melting (SLM) is another rapid additive manufacturing technique. In SLM, a laser is used to melt and fuse the metallic powder together. A roller spreads the metallic powder across the print bed and as the laser finishes to print the layers, the print bed is lowered and the process is repeated. Unlike SLS, SLM requires supports for overhangs since the material is heavier.

Electron Beam Melting (EBM)

Electron Beam Melting (EBM) is an additive manufacturing technology used to print metal parts. The printing process takes place in a vacuum chamber where a high-energy electron beam fuses the metallic powder to create, layer by layer, the desired parts. This technique is very fast and allows the construction of complex and highly resistant objects. EBM machines and materials are expensive, so this technology is mostly used by high-value industries.

Laminated Object Manufacturing (LOM)

Laminated Object Manufacturing (LOM) is a fast additive manufacturing process that creates models by using paper, plastic, or metal laminates. The material is successively glued together using heat and pressure, and the desired shape of the object is cut with a laser cutter.

3D Printing Software

Popular CAD software for 3d printing

Blender

Blender is free and open-source software that supports the entirety of the 3D pipeline. It is an amazing program for artistic design, where you care more about the natural appearance of lifelike forms than dimensional accuracy. As it is open-source Python developers can use Blender’s API to create their own tools (full review).

ZBrush

ZBrush is the king of digital sculpting as it has an immense and refined selection of sculpting brushes. This software can handle a very high polygon count which allows designers to create incredibly detailed models. A paid subscription is required in order to use the program (full review).

SketchUp

SketchUp is a browser-based 3D computer-aided design software with free and paid versions. It is a great software for beginners interested in construction and interior design as it is one of the easiest 3D CAD modeling programs to get started in the 3D designing world (full review).

Fusion360

Fusion360 is a cloud-based 3D CAD software for product design and manufacturing. It is best used for accurate modeling which is why it is perfect for functional 3D printing where exact tolerances and specific angles are required. For professional use, you need to pay a subscription, but it is free for personal needs (full review).

FreeCAD

FreeCAD is a free and open-source 3D parametric modeler software. This program is meant to be used to design models for mechanical purposes like accurate replacement parts and elaborated technical objects. As FreeCAD is fully parametric it is not recommended for modeling organic shapes (full review).

SolidWorks

SolidWorks is popular computer-aided design software considered an industry-standard for engineering. It is focused on the parametric design so organic modeling is not very practical with this program. SolidWorks was primarily developed to build mechanical objects that integrate mechanisms and assemblies. A paid license is required to use this software (full review).

Tinkercad

Tinkercad is free browser-based 3D design software. It is a great tool to introduce kids to the wonders of 3D modeling as it is fairly easy to get the basic concepts with it. In Tinkercad, you design using a preset catalog of shapes which limits your options, but you can still make some amazing models with them (full review).

Popular Slicers for 3d printing

Cura

Cura is a very popular free open-source slicing application for 3D printers. This is a simple and accessible slicer for both beginners and experts alike. Beginners will soon find out how easy it is to use this software with its friendly, clear interface, and the recommended preset settings. For experts, there are over 400 settings you can tweak to get the results you want (view slicer comparison).

Simplify3D

Simplify3D is a paid 3D slicer program. Because of its cost, it is mostly used by professionals for commercial purposes. Simplify3D gives users the opportunity to work with multiple processes. You can set different parameters for different objects on the print bed and even different layer heights to the same model. Also, Simplify3D is a fast slicer and can import massive files and display them in no time (view slicer comparison).

KISSlicer

KISSlicer is a slicing application for 3D printers with both a free and a paid version. Most makers will find the Free version satisfies their needs but some may want more advanced settings found in the Pro version, like dual extrusion options. This slicer is easy to use and yet has many advanced slicing features for quality prints.

Slic3r

Slic3r is an excellent free and open-source slicing software for 3D printers. This slicer is better suited for experts as it has way too many settings and experimental features. Slic3r is an all-around program that can pick up anything you throw at it, it can even be used for SLA prints.

OctoPrint

OctoPrint is a free and open-source remote 3D printer controller application. With a WiFi-enabled device, like a Raspberry Pi, connected to the 3D printer you get complete control over your prints via a web browser or handheld device. Additionally, OctoPrint can slice STls files as it has CuraEngine integrated.

PrusaSlicer

PrusaSlicer is a free open-source software based on Slic3r. This program provides three modes for use, beginner, advanced, and expert. These modes in conjunction with the clear and simple user interface make the software user-friendly. This feature-rich software can be used for both FDM and resin printers (view slicer comparison).

File Formats

STL

STL is the most commonly used file format in 3D printing. When the modeling process is finished, the object is saved as an STL file, which stores the information about the 3D model as a mesh of tessellated triangles.

Most 3D printers can not interpret STLs directly, so the file is converted into G-code before printing. STL files only contain information about the surface geometry of a 3D model. There is no information about color, texture, nor does it check the geometry stability of the object which can lead to errors.

G-code

3D printers (and most CNC machines) read G-code to get instructions on how to print a model. G-code provides in sequence all the commands (extrusion movements, temperature, fans, speed, etc) the 3D printer will execute to print the desired model.

OBJ

OBJ is another popular file format used to save a project when the modeling process is over. OBJ can store a model’s surface geometry, color, and texture. With OBJ you can get smoother surfaces as it can use different kinds of polygons.

AMF

AMF was meant to replace STL as the main file format in 3D printing. Designed to be faster, AMF has native support for file specifications like surface geometry, color, material, and orientation. However, AMF is not universally supported in the 3D printing industry.

3MF

3MF is an open-source file format for additive manufacturing that is gaining popularity in the 3D printing industry. 3MF is highly accurate and can store manufacturing data like slicer settings in addition to all the relevant information about a model (surface geometry, color, and texture). These files are usually error-free and ready to print.

VRML and X3D

VRML and its successor X3D are standard file formats used to represent 3D interactive world objects on the web. Surface geometry, color, and texture can be specified within these files. Some slicers can read these file formats directly.

DWG

DWG (drawing) is a proprietary binary file format that contains all the data about a CAD project. DWG is the native format for several CAD software and is mostly used by engineers, designers, and architects.

F3D

F3D is the native file format used by Fusion360 to store local archives of models, designs, and assets.

DXF

DXF is a CAD data file format developed by Autodesk. DXF was created to enable data interoperability between AutoCAD and other software.

STEP

The STEP file format is used for interoperability between all CAD programs. This open-source file format can precisely describe any shape employing mathematical representations of 3D geometry (NURBS).

SAT

SAT files store 3D geometry data within a standard text file format. The format is supported by many 3D CAD software so it can be used for interoperability and is saved in Spatial’s ACIS solid modeling format.

X3G

X3G is a toolpath file format developed by MakerBot. It is a simplified and efficient alternative of G-code that is easier for the MakerBot printers to handle.

Check out our recommended products section

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

Error processing API data.